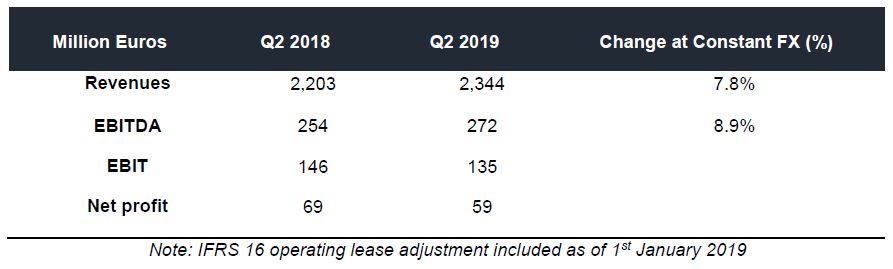

Gestamp, the multinational company specialized in the design, development and manufacture of highly engineered metal components for the automotive industry, has presented its results for Q2 and H1 2019. The second quarter experienced a positive evolution with better performance than in Q1, especially when taking into account the challenging environment seen during Q2. Reported revenues… Continue reading 25.07.2019 Gestamp recorded revenues of €4,513m in the first semester Ge…

Category: Suppliers

Nidec Revises Downward Consolidated Financial Forecasts for the Fiscal First-Half of the Year Ending March 31, 2020

Original Article

Supplementary Financial Data (April-June 2019)

Original Article

Magna Celebrates the Signing of Its First Complete Vehicle Manufacturing Joint Venture in China

JV to have capacity of up to 180,000 vehicles per yearFirst production of electric vehicles planned to be launched in late 2020Capability to offer EV contract manufacturing services to other potential customersZHENJIANG, China, July 24, 2019 (GLOBE NEWSWIRE) — Today Magna, BAIC Group and the Zhenjiang government celebrated the signing of a framework agreement governing… Continue reading Magna Celebrates the Signing of Its First Complete Vehicle Manufacturing Joint Venture in China

Financial Results (April-June 2019)

Original Article

Presentation Material (April-June 2019)

Original Article

News Coverage: Velodyne and Kaarta Technologies Team for Fast, Easy Surface Mapping.

July 24, 2019 Lidar technology can enable ground surface mapping solutions that help city governments plan for infrastructure improvements as well as parking and traffic management. Spencer Chin wrote a FierceElectronics story about how Kaarta has included Velodyne’s lidar technology in the new Kaarta Stencil 2-32 ground surface mapping solution. He noted that Stencil 2-32… Continue reading News Coverage: Velodyne and Kaarta Technologies Team for Fast, Easy Surface Mapping.

Velodyne Lidar Acquires Mapper.ai for ADAS Launch

July 22, 2019 Velodyne adds Mapper’s mapping and localization software to advance revolutionary lidar-centric ADAS In addition to ADAS, Velodyne will incorporate Mapper technology into lidar-centric solutions for other emerging applications, including autonomous vehicles, last-mile delivery services, security, smart cities, smart agriculture, robotics, and unmanned aerial vehicles. Velodyne Lidar, Inc. today announced it has acquired… Continue reading Velodyne Lidar Acquires Mapper.ai for ADAS Launch

AEye Redefines the Three “Rs” of LiDAR – Rate, Resolution, and Range

Company’s Intelligent Sensor Extends Metrics for Evaluating Automotive LiDAR System Performance

Pleasanton, CA – July 18, 2019 – In a new white paper released today, artificial perception pioneer AEye proposes newly extended metrics for evaluating advanced LiDAR system performance. Industry leaders recognize that the conventional metrics of frame rate, angular resolution, and detection range currently used for evaluating LiDAR performance no longer alone adequately measure the effectiveness of sensors to solve real world use cases that underlie autonomous driving. In response, AEye has proposed three new extended metrics for LiDAR evaluation: intra-frame object revisit rate, instantaneous enhanced resolution, and object classification range. The AEye white paper describes these capabilities and why they matter within the context of real-world automotive applications.

“Current metrics used for evaluating LiDAR systems designed for autonomous driving often fail to adequately address how a system will perform in real-world conditions,” said AEye co-founder and CEO, Luis Dussan. “These extended metrics are more apropos to measuring advanced LiDAR performance, and are key to evaluating systems that will solve the most challenging use cases.”

First generation LiDAR sensors passively search a scene and detect objects using scan patterns that are fixed in both time and in space, with no ability to enhance performance with a faster revisit nor to apply extra resolution to high interest areas like the road surface or intersections. A new class of advanced solid-state LiDAR sensors enable intelligent information capture that expands the capabilities of LiDAR and moves from passive “search” or detection of objects to active search and, in many cases, to the actual acquisition and classification attributes of objects in real-time making perception and path planning software safer and more effective.

Extended Metric #1: From Frame Rate to Object Revisit Rate

It is universally accepted that a single interrogation point, or shot, does not deliver enough confidence to verify a hazard. Therefore, passive LiDAR systems need multiple interrogations/detects on the same object or position over multiple frames to validate an object. New, intelligent LiDAR systems, such as AEye’s iDAR™, can revisit an object within the same frame. These agile systems can accelerate the revisit rate by allowing for intelligent shot scheduling within a frame, with the ability to interrogate an object or position multiple times within a conventional frame.

In addition, existing LiDAR systems are limited by the physics of fixed laser pulse energy, fixed dwell time, and fixed scan patterns. Next generation systems such as iDAR, are software definable by perception, path and motion planning modules so that they can dynamically adjust their data collection approach to best fit their needs. Therefore, Object Revisit Rate, or the time between two shots at the same point or set of points, is a more important and relevant metric than Frame Rate alone.

Extended Metric #2: From Angular Resolution to Instantaneous (Angular) Resolution

The assumption behind the use of resolution as a conventional LiDAR metric is that the entire Field of view will be scanned with a constant pattern and uniform power. However, AEye’s iDAR technology, based on advanced robotic vision paradigms like those utilized in missile defense systems, was developed to break this assumption. Agile LiDAR systems enable a dynamic change in both temporal and spatial sampling density within a region of interest, creating instantaneous resolution. These regions of interest can be fixed at design time, triggered by specific conditions, or dynamically generated at run-time.

“Laser power is a valuable commodity. LiDAR systems need to be able to focus their defined laser power on objects that matter, said Allan Steinhardt, Chief Scientist at AEye. “Therefore, it is beneficial to measure how much more resolution can be applied on demand to key objects in addition to merely measuring static angular resolution over a fixed pattern. If you are not intelligently scanning, you are either over sampling, or under sampling the majority of a scene, wasting precious power with no gain in information value.”

Extended Metric #3: From Detection Range to Classification Range

The traditional metric of detection range to may work for simple applications, but for autonomy the more critical performance measurement is classification range. While it has been generally assumed that LiDAR manufacturers need not know or care about how the domain controller classifies or how long it takes, this can ultimately add latency and leave the vehicle vulnerable to dangerous situations. The more a sensor can provide classification attributes, the faster the perception system can confirm and classify. Measuring classification range, in addition to detection range, will provide better assessment of an automotive LiDAR’s capabilities, since it eliminates the unknowns in the perception stack, pinpointing salient information faster.

Unlike first generation LiDAR sensors, AEye’s iDAR is an integrated, responsive perception system that mimics the way the human visual cortex focuses on and evaluates potential driving hazards. Using a distributed architecture and edge processing, iDAR dynamically tracks objects of interest, while always critically assessing general surroundings. Its software-configurable hardware enables vehicle control system software to selectively customize data collection in real-time, while edge processing reduces control loop latency. By combining software-definability, artificial intelligence, feedback loops, with smart, agile sensors, iDAR is able to capture more intelligent information with less data, faster, for optimal performance and safety.

AEye’s iDAR system uniquely architected to scale from modular ADAS solutions to fully integrated mobility/robot-taxi implementations. In order to deliver automotive-grade ADAS solutions at scale, AEye has partnered with top Tier 1 global automotive suppliers such as Hella, LG Electronics, and Aisin to design and manufacture best-in-class ADAS systems to global automakers. In addition, the company is engaged in pilots with more than a dozen non-disclosed OEMs and mobility companies.

“To create an effective sensing system, two things matter most – the quality of the data and the speed at which you can make it actionable,” said AEye Co-Founder and SVP of Engineering, Barry Behnken. “Performance metrics matter because they determine how designers and engineers approach problem-solving. These extended metrics help the industry focus on what matters most.”

About AEye

AEye is an artificial perception pioneer and creator of iDAR™, a perception system that acts as the eyes and visual cortex of autonomous vehicles. Since its demonstration of its solid-state LiDAR scanner in 2013, AEye has pioneered breakthroughs in intelligent sensing. The company is based in the San Francisco Bay Area, and backed by world-renowned investors including Kleiner Perkins Caufield & Byers, Taiwania Capital, Hella Ventures, LG Electronics, Subaru-SBI, Aisin, Intel Capital, Airbus Ventures, and others.

Media Contact:

AEye, Inc.

Jennifer Deitsch

[email protected]

925-400-4366

AEye Redefines the Three “Rs” of LiDAR – Rate, Resolution, and Range — AEye Sets New Benchmark for LiDAR RangeAEye Advisory Board Profile: Luke SchneiderBlair LaCorte Named President of AEyeAEye Team Profile: Vivek ThotlaElon Musk Is Right: LiDAR Is a Crutch (Sort of.)SAE's Autonomous Vehicle Engineering on New LiDAR Performance MetricsLeading Global Automotive Supplier Aisin Invests in AEye through Pegasus Tech VenturesAEye Advisory Board Profile: Tim ShipleAEye Team Profile: Indu Vijayan

Revision of Outlook for Fiscal 2019 and Preliminary Q2 Key Data

Due to the following factors, Continental’s previous outlook for the 2019 fiscal year issued on May 9, 2019 will no longer be achievable: Whereas the previously communicated outlook was based on expectations of a flat development in global light vehicle production in fiscal 2019 versus the previous year, current expectations are for a decline of… Continue reading Revision of Outlook for Fiscal 2019 and Preliminary Q2 Key Data