On the surface, this looks like an ordinary class 3 electric delivery van – one with a crazy-low floor, extra-large cargo space and gratuitous rear-wheel steering. But its entire drivetrain, suspension and steering systems live in the wheel arches.

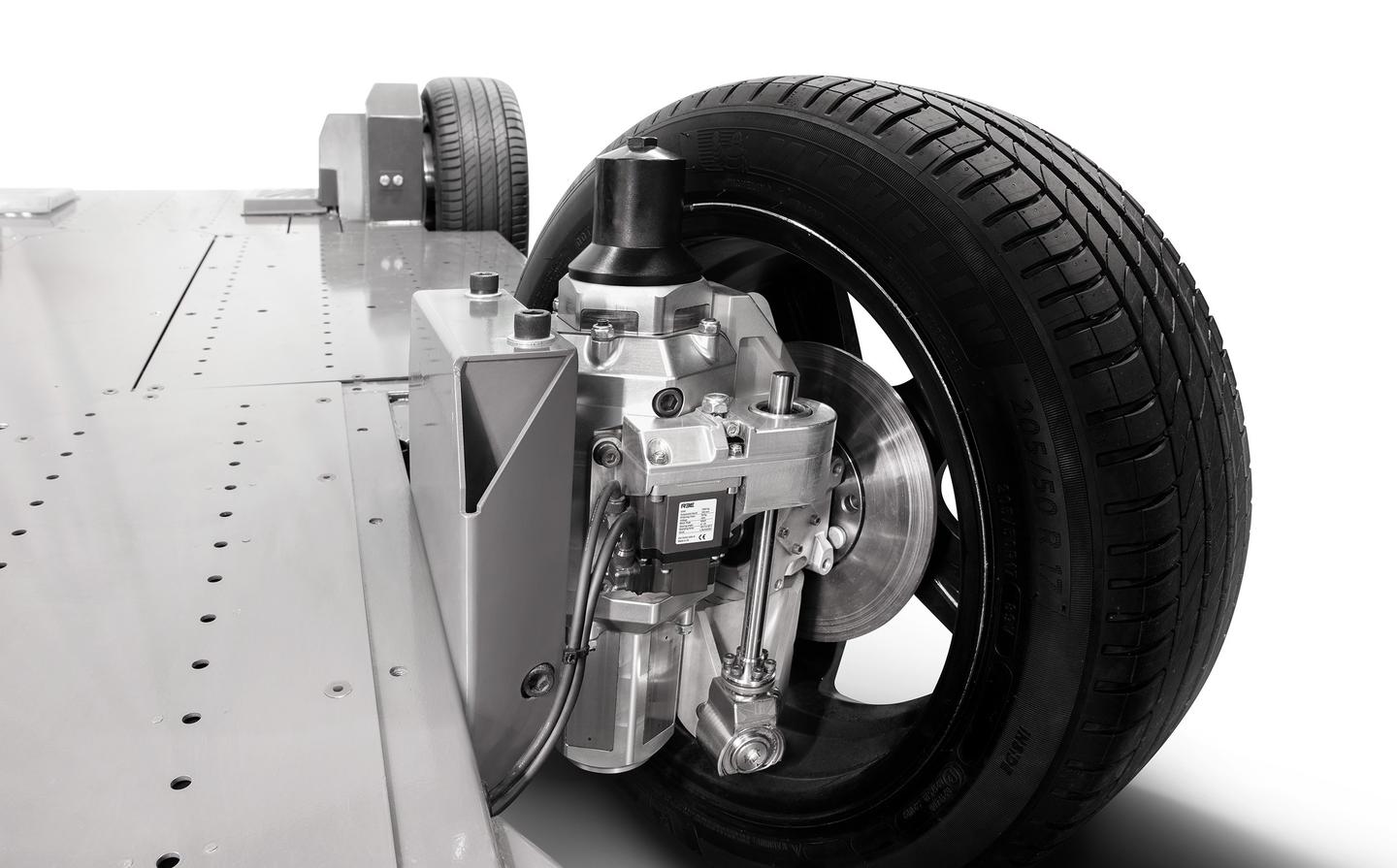

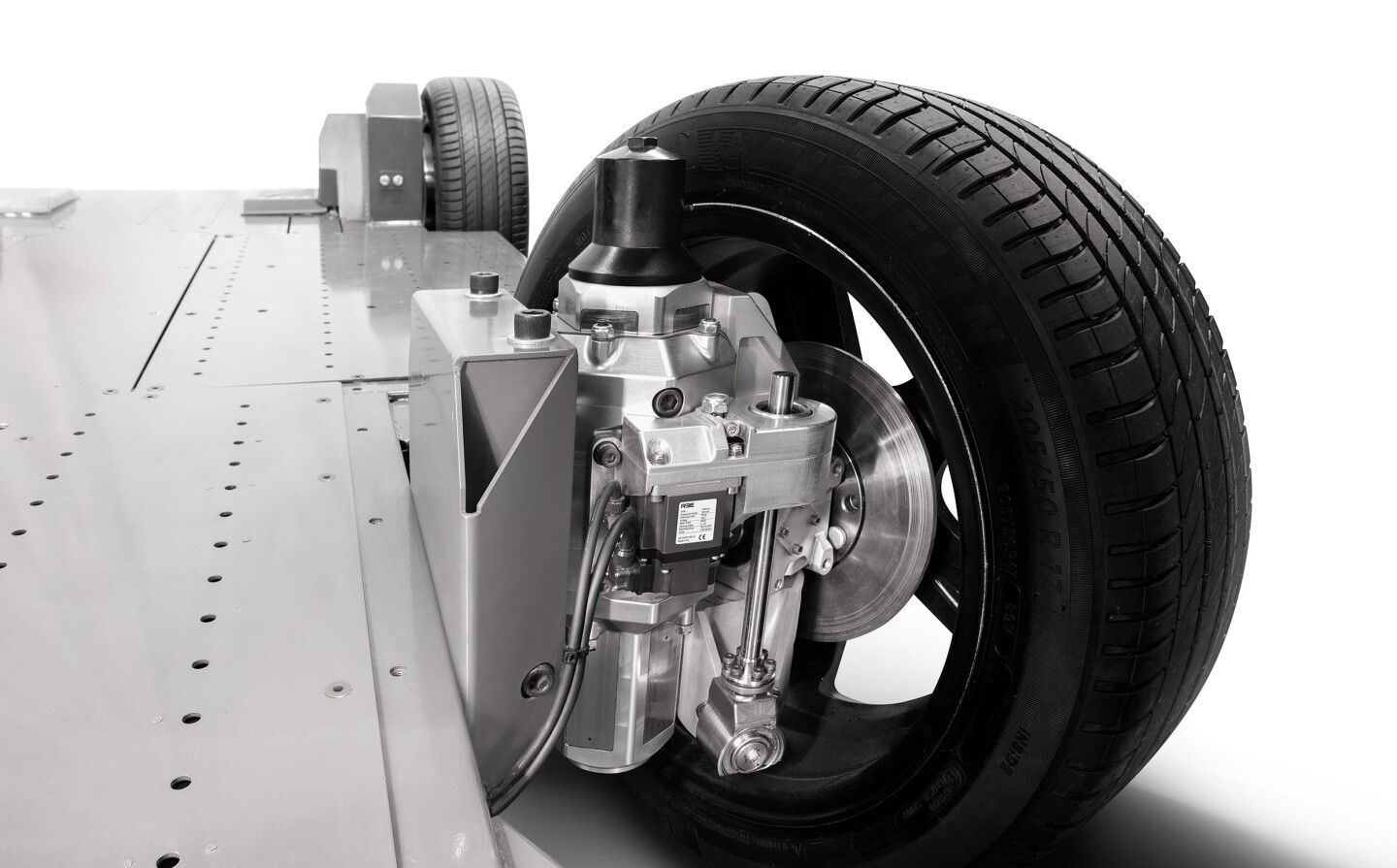

The P7-B is the latest customer evaluation vehicle built on top of REE’s ultra-modular, ultra-flat electric vehicle chassis. We’ve written about REE’s extraordinary chassis designs in the past, but what sets this company apart is its super-flexible REEcorner modules.

Every REE chassis starts with a skateboard-flat battery pack, built into a tough, structural casing. But where other EVs place motors, steering systems and other functional chassis components throughout the vehicle, REE packs the lot into bolt-on corner modules specified however you’d like them. It’s an everything-by-wire system; everything from steering to acceleration to braking inputs gets sent electronically to the corner modules – so the REE chassis, in effect, neither knows nor cares whether instructions are coming from a human driver or an autonomous system.

REE Automotive

The flexibility this system allows is enormous. As the P7-B demonstrates, it’s just as easy to put steering systems on the rear wheels as the front ones. Automakers can specify their desired drivetrain, suspension, brakes, motor torque and performance characteristics off the rack, or custom-built from a collection of REE’s tier-one supply partners, and then go ahead and design whatever sort of body and interior they want to go on top.

In this case, it’s a box truck running a meaty 400-kW (536-hp) all-wheel-drive system. It carries enough battery for a 150-mile (241-km) range, with a max speed of 75 mph (120 km/h). It’ll carry up to 4,400 lb (2,000 kg) of cargo, with an 812-cu-ft (23-cu-m) space to put it in, and a minimum load floor height of 23 inches (58 cm). And the turning radius is just 19 ft (6 m), since it’s been specified with steering systems in the rear corner modules as well as the front ones.

As with all REE-platform vehicles, if something in the drivetrain fails, the van needn’t stay off the road while it’s being fixed. Pull off the offending corner module, bolt on a spare, and you’re back on the road – an attractive prospect for fleet owners.

REE

The P7-B is the second evolution of this delivery van concept, built after customer feedback around the Proxima-bodied prototype we saw as recently as July. In this case, REE went ahead and built the body itself, but the company is working hard to get it – or something close – into production in both the UK and US, for fleet clients.

“The on-track testing of the P7-B and extensive customer evaluations are another crucial step on the road to commercialization and deployment of test fleets followed by scale adaptation in fleets,” said Tali Miller, chief business officer at REE. “Feedback from our customers has been that this is the truck they have been waiting for – a driver-centric work truck that drives like a saloon car but is built to deliver under the harshest commercial duty cycle. Our modular P7 chassis allows us to design vehicles tailored to our customers’ needs and we are excited to be showing them what our unique technology affords their fleets as we support them on their path towards electrification and carbon neutrality.”

Check out a video below.

REE P7-b electric box truck

Source: REE