Most kaizens, or changes that promote continuous improvement, are small but can have a significant cumulative effect. Occasionally, though, a low-cost change comes along that generates massive savings. Toyota West Virginia has come up with just such an extraordinary innovation.

Continuous improvement, or the kaizen process, is the secret sauce that makes Toyota, well, Toyota. Most kaizens are small but can have a huge cumulative effect. Every once in a while, though, a low-cost change comes along that generates massive savings.

Toyota West Virginia’s cam chatter checker is one of those extraordinary innovations.

The Problem

Some 2,000 team members at the plant in Buffalo, West Virginia, make nearly 1 million engines and transmissions annually. A key component in their output is the camshaft which must be machined to very tight tolerances to function properly. If the camshaft’s lobes aren’t spot on, it can result in unacceptable chatter noise when the completed engine is powered up. At that point, the only way to fix the problem is to shut down the production line, deconstruct the affected engines and replace the faulty camshafts.

“Just one failed test can cause a quarter of production — or about 135 engines — to be placed on hold,” says Cheryl Rollins, team leader in Quality Control at the plant. “That almost always requires scheduling weekend work to fix the problem.”

Encouraged by the team members on the front lines, Rollins and her team set out five years ago to come up with a way to identify cam chatter earlier in the production process.

The Kaizen

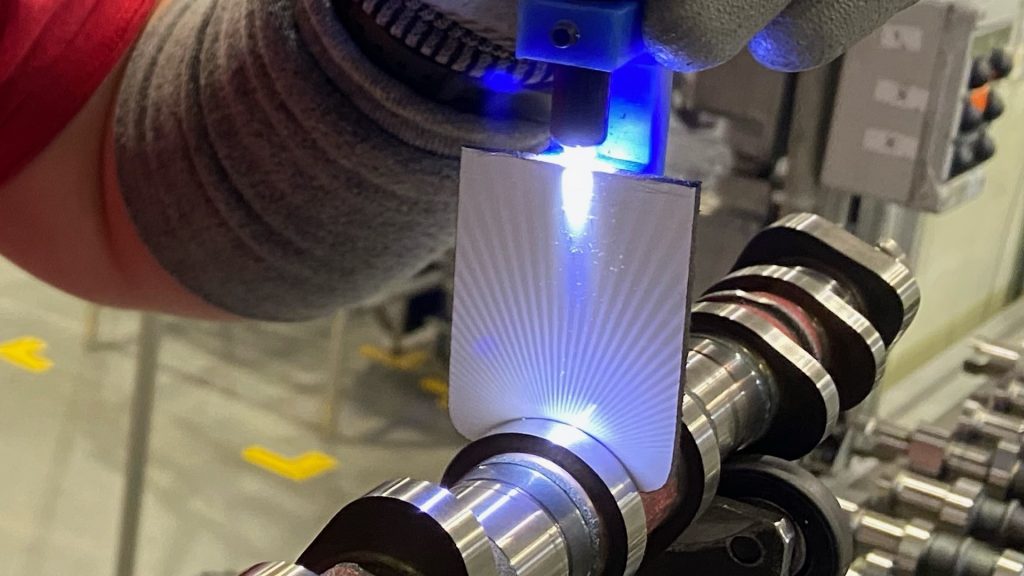

By applying Toyota Production System principles, the team drilled down to the root cause of the problem and came up with an elegant and incredibly affordable camshaft chatter checker tool. It’s comprised of an LED stream light, a small white board and a bit of nylon to hold it all together at the required angles. The team member conducting the inspection simply aligns the tool with the camshaft, turns on the LED and examines the pattern that appears on the whiteboard when the light reflects off a specific lobe.

If all is well, the light will bounce off the lobe and onto the white board in one continuous flood of light. But if there are imperfections in the machined surface, a radial pattern of shadows will appear on the board — what the team refers to as “fanning.” The more prominent the shadows, the more significant the flaws. And, in turn, the louder the resulting engine noise if that camshaft were to find its way into production.

West Virginia’s team members don’t check every camshaft, only a representative sample. But since the checker has been put into use, the plant hasn’t had a single shutdown requiring extra work shifts due to this problem. All of the flawed components have been identified and replaced earlier in the production process.

The Savings

In hard costs, Rollins says the impact of an assembly line shutdown due to cam chatter was in the neighborhood of $500,000 per incident. Even if the cam chatter checker has prevented just one such occurrence, it has already paid for itself many times over. And that’s before factoring in the impact such disruptions can have on the lives and morale of the team members directly affected by it or the delayed production of engines that are in such very high demand right now.

Meanwhile, Rollins and her team applied for and were granted a patent for their invention. And their colleagues at Toyota Alabama, which churns out 3,000 engines per day, have also incorporated the innovation into its quality control processes.

“The loss of containment used to cause a lot of frustration on the line,” Rollins says. “They came to us and said, ‘Please come up with something.’ It’s incredibly satisfying to respond to the challenge and to receive the validation of the patent, which, as far as we know, is the only one of its kind in the U.S. It really makes you proud to work for a company like Toyota.”

By Dan Miller

Originally published February 3, 2023

Add to Cart

Add to Cart Print

Print Convert to PDF

Convert to PDF