Mar. 09, 2023

Toyota City, Japan, March 9, 2023―Toyota Motor Corporation (Toyota) has been working with Fukushima Prefecture since June 2021 toward the development of new future cities using both hydrogen produced in Fukushima and hydrogen-related technologies developed there. As part of these efforts, Toyota has been collaborating with the DENSO Group to use hydrogen along with renewable energy to decarbonize plants.

Toyota recently developed new electrolysis equipment that produces hydrogen from electrolyzing water using the FC stack and other technology from the Mirai. The equipment will be put into operation this March at a DENSO Fukushima Corporation plant, which will serve as a technology implementation venue to promote its widespread use going forward. Toyota will accelerate its efforts to build a model for the local consumption of locally produced hydrogen, using electrolysis equipment to produce clean hydrogen and combust it in one of the plant’s gas furnaces.

Furthermore, Toyota will publicize the details of its efforts to build such a hydrogen utilization model in the hopes of expanding the model’s implementation to many people from various industries and regions.

The hydrogen utilization at DENSO Fukushima will be implemented as a project subsidized by the New Energy and Industrial Technology Development Organization (NEDO).

Toyota has positioned hydrogen as a critical fuel for promoting initiatives aimed at reducing CO2 emissions to contribute to achieving carbon neutrality. In doing so, it aims to promote the use of hydrogen not only through fuel cell electric vehicles (FCEVs) including passenger cars, commercial trucks, and buses, but also through the widespread use of fuel cell (FC) products, such as the development and test operation of FC stationary generators. To this end, Toyota is working with various industry partners in the areas of producing, transporting, storing, and using hydrogen.

Toyota has been using hydrogen for FCEVs, FC stationary generators, production at plants, etc. to date. It has also promoted transporting activities, such as the development and manufacturing of FC trucks for hydrogen transportation. In the future, Toyota hopes to contribute to expanding options for producing hydrogen using biogas generated from livestock manure in Thailand in addition to developing electrolysis equipment.

Features of the Electrolysis Equipment

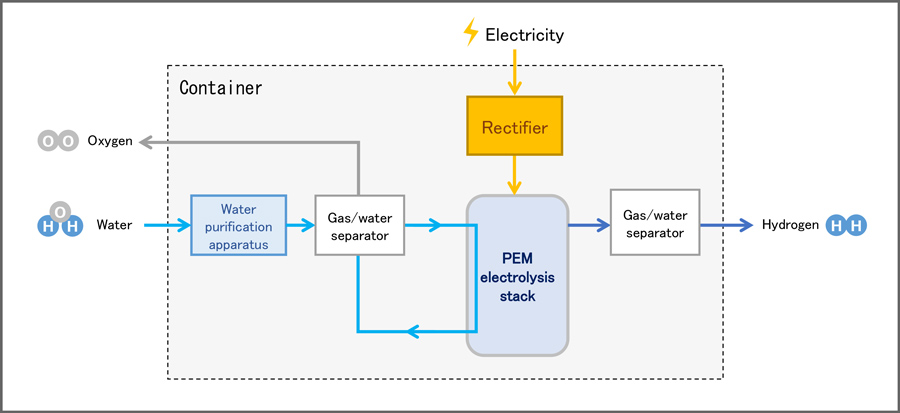

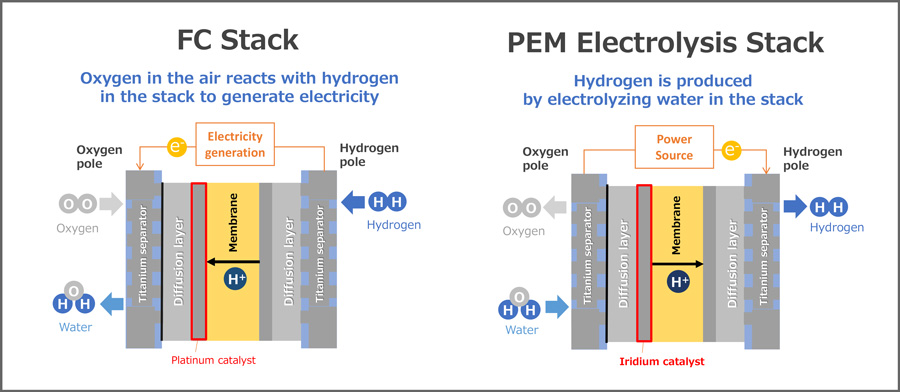

The electrolysis equipment, which utilizes the FC stack from the Mirai and Sora FC bus, is newly developed equipment that takes advantage of both the technology Toyota has cultivated over many years of FCEV development and the knowledge and expertise it has accumulated from a variety of usage environments around the world. Its features are as follows:

- The cells used in the Proton Exchange Membrane (PEM) electrolysis stack are highly reliable, backed by the mass production and usage results of more than seven million cells (enough for approximately 20,000 FCEVs) since the first-generation Mirai was launched in December 2014.

- Toyota has used titanium for the stack separator, which was developed for FCEVs and has been used since the first-generation Mirai. It was developed to improve the durability that is required of electrolysis equipment using titanium’s high corrosion resistance maintaining almost the same level of performance even after 80,000 hours of operation so that it can be used safely over a long period of time.

- More than 90% of FC stack components for FCEVs and FC stack production facilities can be used/shared in the PEM electrolysis stack production process. This will allow for mass production to achieve a cost level that enables its widespread use. Furthermore, it significantly shortens the development period by using the technology, knowledge, and experience accumulated over many years of FCEV development.

Overview of the Electrolysis Equipment

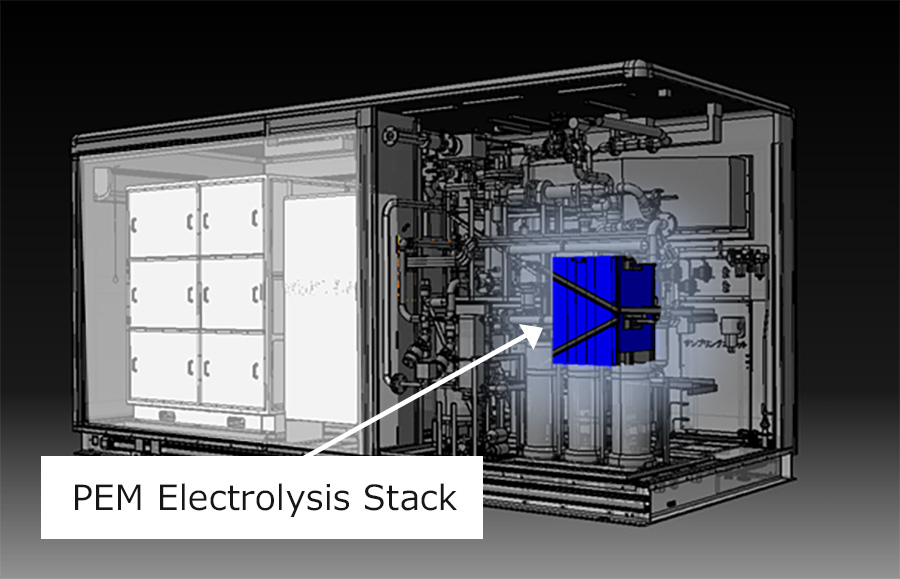

Mid-development images

Appearance (As installed at DENSO Fukushima)

Internal structure of the electrolysis equipment

| Size (L x W x H) | Approx. 2.3 m x 5.8 m x 2.8 m |

|---|---|

| Hydrogen production capacity | Approx. 8 kg/hour |

| Hydrogen production energy | 53 kWh/1 kg of hydrogen production |

| Stack type | Proton Exchange Membrane (PEM) |

Numerical values are targets and subject to change.

Electrolysis equipment configuration

Stack usage: FC and electrolysis

Toyota will be exhibiting the stack utilized in the electrolysis equipment and other conceptual models at the FC Expo (International Hydrogen & Fuel Cell Expo) to be held at Tokyo Big Sight (Koto-ku, Tokyo) from March 15 to 17.

Related News

“Achieving zero, and adding new value beyond it”

As part of efforts to pass our beautiful “Home Planet” to the next generation, Toyota has identified and is helping to solve issues faced by individuals and overall society, which Toyota calls “Achieving Zero,” hoping to help reduce the negative impacts caused by these issues to people and the environment to zero. Additionally, Toyota is also looking “Beyond Zero” to create and provide greater value by continuing to diligently seek ways to improve lives and society for the future.

- About Beyond Zero

- https://global.toyota/en/mobility/beyond-zero/

Toyota Motor Corporation works to develop and manufacture innovative, safe and high-quality products and services that create happiness by providing mobility for all. We believe that true achievement comes from supporting our customers, partners, employees, and the communities in which we operate. Since our founding over 80 years ago in 1937, we have applied our Guiding Principles in pursuit of a safer, greener and more inclusive society. Today, as we transform into a mobility company developing connected, automated, shared and electrified technologies, we also remain true to our Guiding Principles and many of the United Nations’ Sustainable Development Goals to help realize an ever-better world, where everyone is free to move.

- SDGs Initiatives

- https://global.toyota/en/sustainability/sdgs/