Haute Couture is the epitome of fashion, developing custom designs for high-end fashion and not an industry usually associated with springs. However, Lesjöfors recently created its own haute couture spring for a leading global fashion brand.

In a development project for the Swedish truck and trolley manufacturer, Helge Nyberg, Lesjöfors Industrifjädrar in Herrljunga pushed the boundaries of their coiling wire diameters to deliver a unique project.

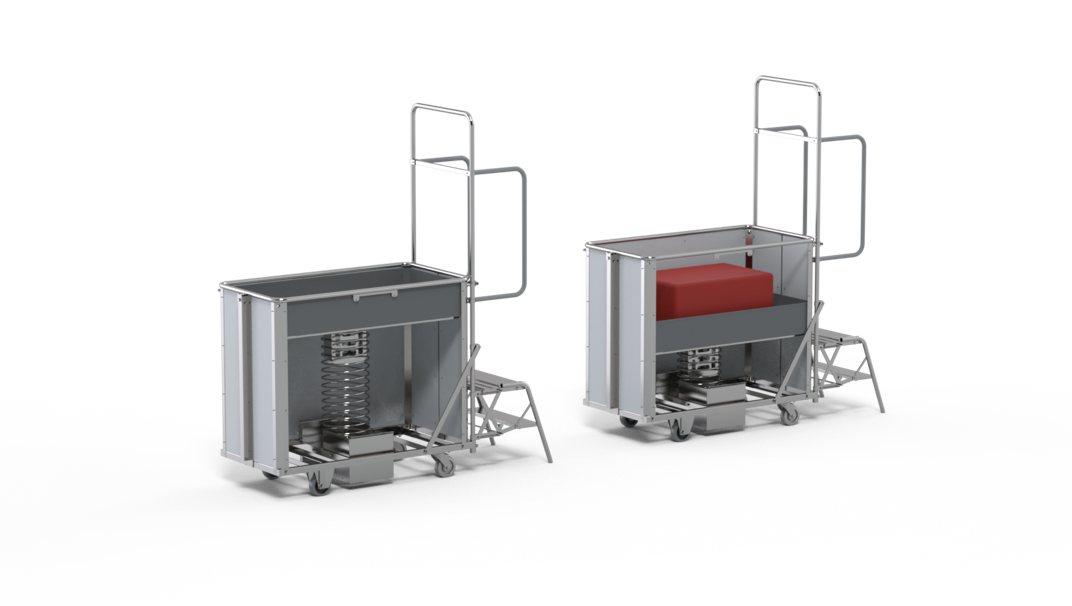

Tasked by their fashion client with designing a step trolley with a ‘springy shelf’, Helge Nyberg challenged the team at Lesjofors to secure the spring solution.

Having supplied stock springs for Helge Nyberg’s standard range products, the Herrljunga based manufacturing site of the Lesjofors Group has been a long-term supplier of quality, lifetime guarantee springs for decades. The requirements by the fashion house demanded a new level of bespoke component supply for this newly commissioned and customised specific trolley and this is where the challenge lied.

Experts in the field of customised trolleys, Helge Nyberg’s R&D manager, Patrik Ignell, turned to Lesjöfors: “Our customer required a trolley with a loading shelf that automatically lowered when loading. Since we already had a good relationship with Lesjöfors Industrifjädrar, we turned to the Herrljunga unit with the challenging request.”

The technicians seized the opportunity to overcome a spring issue and assessed the drawings but it soon became apparent that the compression spring requirements was initially thought to be too large for the company’s machines.

Not that this was a major issue as the Lesjöfors Group coils wire from 0.3mm to 65mm diameter and the project could have migrated to another of the groups 55+ manufacturing sites. However, a determination to deliver above and beyond for the customer, to keep it local, to deepen the relationship between the key sub contractor site and its customer, saw the technicians expand the existing parameters of their wire coiling facilities.

“Thanks to a deep knowledge of the capacity level of our manufacturing machines and a strong design foundation by our designers, we were able to stretch our machine’s boundaries to find a new way to manufacture the compression spring in the requested dimension. The project proved our operator’s and technical salespeople’s deep competence and ability to think outside the box,” says Christian Olsson, technical manager at Lesjöfors Industrifjädrar.

Multiple volumes of the new spring have been ordered and the fashion industry now features springs as part of its logistics management.

Patrik Ignell, R&D manager for Helge Nyberg concludes: “We have continuous deliveries of the trolleys to the customer and we also provide the model to other customers in this segment. We will definitely turn to Lesjöfors again when we need spring expertise.”

Tamsin Loveless

Communications team, +44 7855 798536

tamsin.loveless@lesjoforsab.com

Lesjöfors Group is one of the largest spring corporations in the world.

Committed to manufacturing excellence, reliability and customer service, our global manufacturing and technological development network is dedicated to world-leading products, delivering quality spring solutions.

Delivering impact to every industry, our customers rely on our products and network, reach, problem-solving agility, purchasing power and flexibility to extend their capabilities.

We provide a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors as the best partner in sustainable spring and pressing solutions.

Tags: