Jul. 29, 2023

Toyota City, Japan, July 29, 2023―Toyota Motor Corporation (Toyota) announced today that it will enter the ENEOS Super Taikyu Series 2023 Supported by Bridgestone Round 4 Super Taikyu Race (5h x 1 race), to be held from July 29 to 30 at the Autopolis international racing course in Oita Prefecture, with the #32 ORC ROOKIE GR Corolla H2 Concept, which runs on liquid hydrogen, and the #28 ORC ROOKIE GR86 CNF Concept running on carbon-neutral fuel.

-

- Hydrogen-powered Corolla

-

- GR86 (carbon-neutral fuel)

- Evolution from the Fuji 24 Hours Race

The hydrogen-powered Corolla, mobile liquid hydrogen stations, and carbon neutral fuel have evolved in the two months since the Round 2 NAPAC Fuji SUPER TEC 24 Hours Race from May 26 to 28.

- Hydrogen-powered Corolla

- Improved durability of liquid hydrogen pump

The durability of the pump, which was an issue in the Fuji 24 Hours Race, has been improved, resulting in 30% enhanced durability under similar conditions. Lubricating oil is usually used in pumps to reduce stress through less friction in the pump; however, lubricating oil cannot be used in liquid hydrogen pumps as it contaminates the hydrogen. For this race, a buffer structure will be used to reduce stress on the pump gear drive unit, aiming to allow it to finish the race without needing to be replaced. - Vehicle weight reduced by 40 kg

Various liquid hydrogen systems, including safety valves and piping, have been optimized based on analyses of data collected in previous tests and races. In addition, pump stress has been reduced by optimizing fuel pressure, leading to a weight reduction for the pump drive motor battery. As a result, the vehicle now weighs 1,910 kg, 40 kg lighter than the 1,950 kg it weighed during the Fuji 24 Hours Race in May.

- Mobile liquid hydrogen stations

- Joint and flexible hose weight reduced

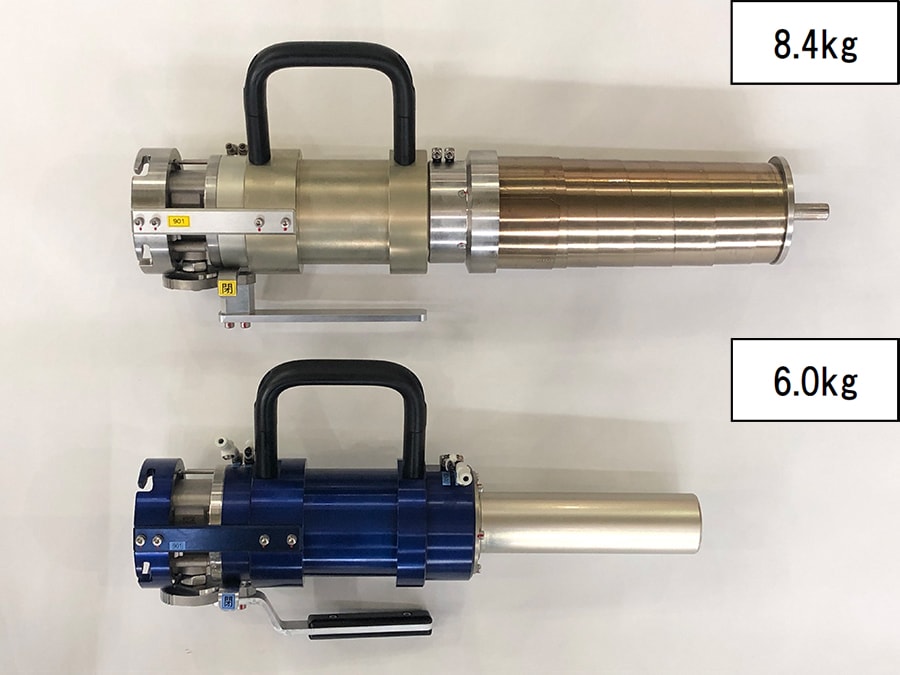

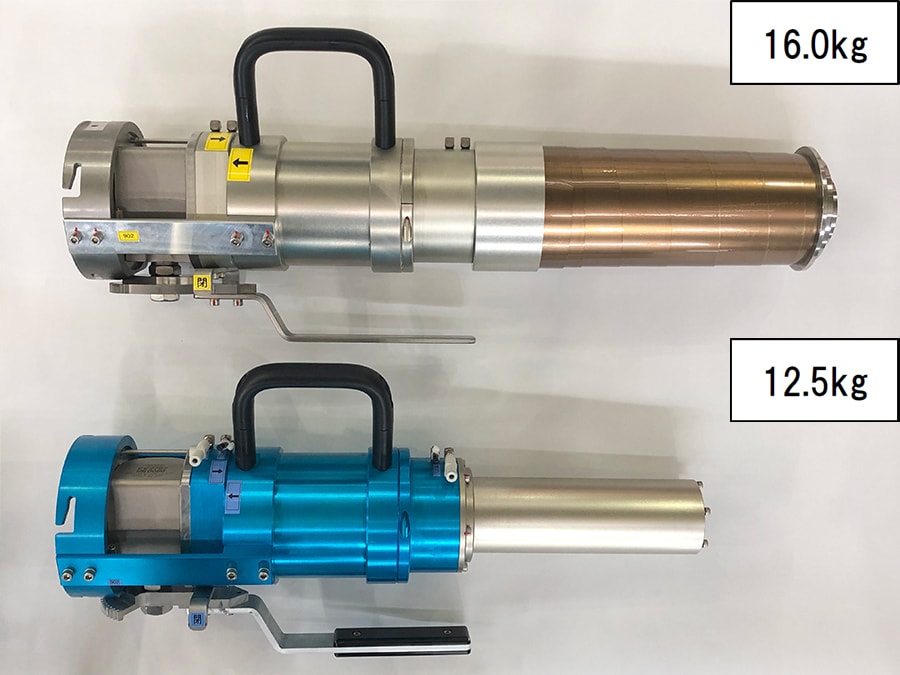

We have succeeded in reducing the weight of joints and flexible hoses for the mobile liquid hydrogen station that was developed jointly by Iwatani Corporation and Toyota. Since the joint and flexible hose weight puts a burden on the workers who fill vehicles with hydrogen, reducing their size and weight is important in preparing for future commercialization. We reduced the weight of the filling joint from 8.4 kg to 6.0 kg and the return joint from 16.0 kg to 12.5 kg by eliminating the connection cover and changing the components that do not come into contact with hydrogen from iron to aluminum. The flexible hose on the return joint side has also been changed to a thinner hose, reducing the weight from approximately 4 kg to 1 kg, to reduce the burden on workers and improve workability during filling operations.

-

- Filling joint*1

-

- Return joint*2

Both pictures show the joint used during the Fuji 24 Hours Race (top) and the improved joint (bottom).

-

- Back: Return joint, front: filling joint

-

- Flexible hose*3 Top is pre-improvement, bottom is post-improvement.

- Automated hydrogen filling operation

Until now, all hydrogen filling operations for the hydrogen-powered Corolla, such as opening and closing the filling valve and stopping filling when the hydrogen reaches full capacity, have been performed manually. For this race, we have succeeded in automating these operations through electronic control. Automating hydrogen filling will enable it to be performed efficiently and error-free in a predictable time frame. - Improved hydrogen filling time

A high-flow-rate filling-side stop valve developed by Fujikin Incorporated will be installed starting from this race. The filling-side stop valve is installed onto the filling port of the liquid hydrogen tank. Valve sizes increase as the flow rate increases to speed up the filling process, making sealing more difficult. However, Fujikin’s valve has succeeded in balancing both of these factors. As a result, hydrogen filling time*4 has been reduced to approximately 1 minute, down from 1 minute 40 seconds at the Fuji 24 Hours Race.

- High-flow-rate filling-side stop valves developed by Fujikin Incorporated (Left is pre-improvement, right is post-improvement)

- Carbon-neutral fuel

The CNF GR86 has been racing with the newly improved carbon-neutral fuel since the Round 3 SUGO Super Taikyu 3 Hours Race held from July 8 to 9.

The problem with traditional carbon-neutral fuel is that it tends to dilute the engine oil, preventing the engine oil from performing as it should. Together with Subaru Corporation, which also uses carbon-neutral fuel in its races, and fuel manufacturers, we adjusted the composition of the fuel to make it easier to vaporize and burn. This reduces engine oil dilution and improves reliability and exhaust performance by reducing the burden on the engine.

- Progress of efforts to achieve carbon neutrality with partners in Kyushu

Our local company and municipality partners in Kyushu, who have come together to achieve carbon neutrality, have been further accelerating their efforts.

Efforts of partners in Kyushu

| Obayashi, Toyota Motor Kyushu, Fukuoka City |

A fuel cell generator has been installed in the pit to power the mobile liquid hydrogen station for the hydrogen-powered Corolla. Three types of Kyushu-produced gaseous hydrogen are being used: geothermal-derived hydrogen from Obayashi Corporation, solar-generated hydrogen from Toyota Motor Kyushu, and sewage biogas-derived hydrogen from Fukuoka City.  |

|---|---|

| Obayashi |

(Announced on January 24, 2023) |

| Fukuoka Prefecture |

Fukuoka Prefecture introduced FC coasters in its BRT (Bus Rapid Transit) system in cooperation with Kyushu Railway and CJPT. It also promotes hydrogen project initiatives, such as supporting the introduction of Light-Duty Fuel Cell Electric Truck to logistics providers. https://global.toyota/en/newsroom/corporate/38377786.html |

| Fukuoka City |

Fukuoka City promotes hydrogen project initiatives, including the introduction of FC school lunch delivery vehicles in collaboration with Toyota and CJPT. A prototype FC garbage truck for technical studies, which is scheduled to be introduced by Fukuoka City and other municipalities, was unveiled for the first time at the Autopolis event square. https://global.toyota/en/newsroom/corporate/36884314.html |

- Fuel cell garbage trucks (prototype for technical study)

Toyota will continue to accelerate development by refining cars and people in the challenging world of motorsports. It will also continue to evolve together with its partners to create an even better carbon-neutral society.

| *1 |

|

|---|---|

| *2 |

|

| *3 |

|

| *4 |

|

“Achieving zero, and adding new value beyond it”

As part of efforts to pass our beautiful “Home Planet” to the next generation, Toyota has identified and is helping to solve issues faced by individuals and overall society, which Toyota calls “Achieving Zero,” hoping to help reduce the negative impacts caused by these issues to people and the environment to zero. Additionally, Toyota is also looking “Beyond Zero” to create and provide greater value by continuing to diligently seek ways to improve lives and society for the future.

- About Beyond Zero

- https://global.toyota/en/mobility/beyond-zero/

Toyota Motor Corporation works to develop and manufacture innovative, safe and high-quality products and services that create happiness by providing mobility for all. We believe that true achievement comes from supporting our customers, partners, employees, and the communities in which we operate. Since our founding over 80 years ago in 1937, we have applied our Guiding Principles in pursuit of a safer, greener and more inclusive society. Today, as we transform into a mobility company developing connected, automated, shared and electrified technologies, we also remain true to our Guiding Principles and many of the United Nations’ Sustainable Development Goals to help realize an ever-better world, where everyone is free to move.

- SDGs Initiatives

- https://global.toyota/en/sustainability/sdgs/