“Over the past year, we have produced more than 888,000 Škoda vehicles globally, demonstrating our ability to adapt quickly and flexibly to a dynamically changing and geopolitically challenging environment. This achievement reflects our commitment to our customers, our brand, and the Group. Our recent new market entries and the addition of local manufacturing facilities are key steps in expanding our global production capacities. I would like to thank all my colleagues for their great commitment and teamwork.”

Andreas Dick, Škoda Auto Board Member for Production and Logistics

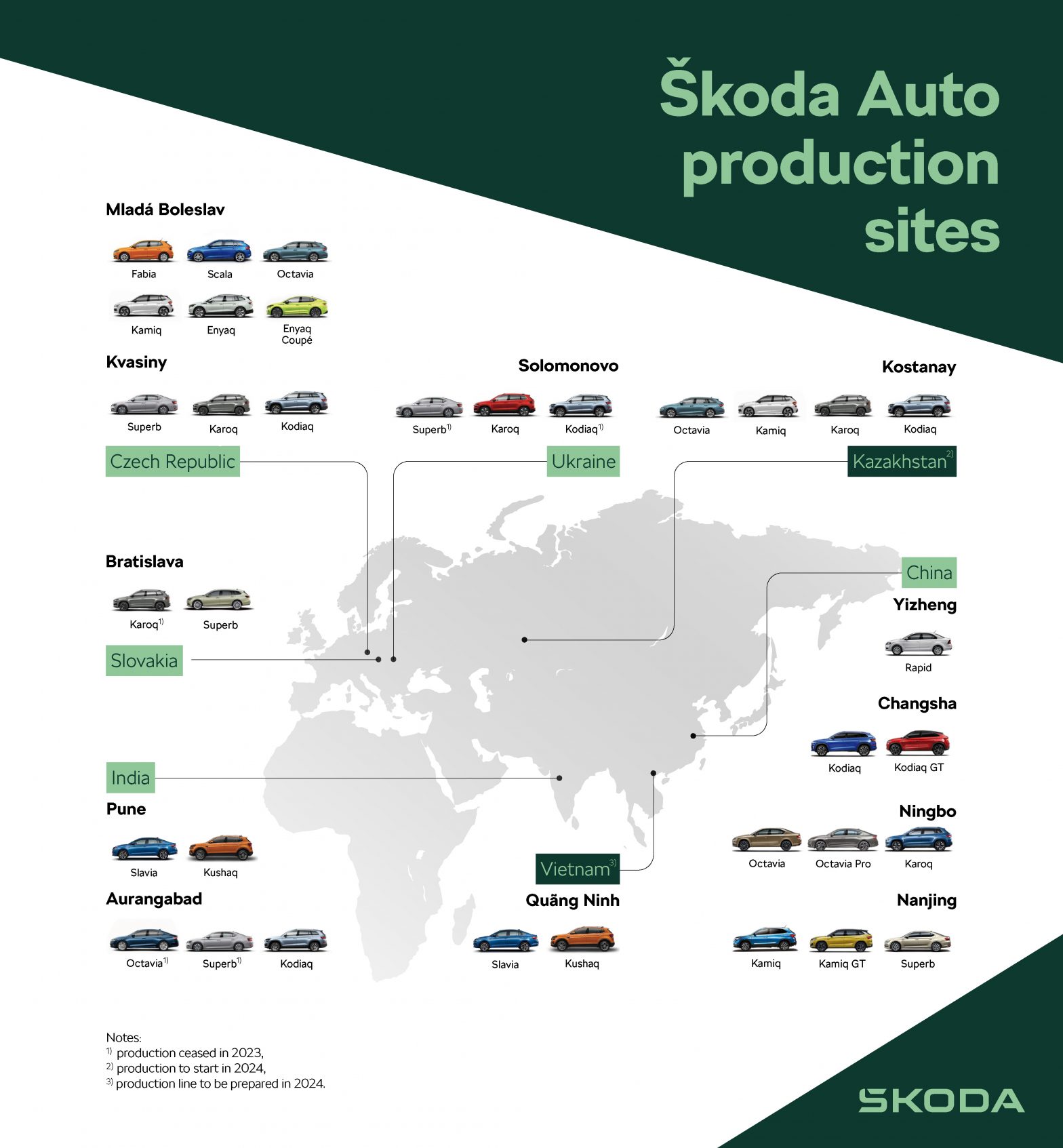

Production in the Czech Republic

In 2023, Škoda Auto manufactured approximately 556,000 units of the Fabia, Scala, Octavia, Octavia iV, Kamiq, Enyaq and Enyaq Coupé series in Mladá Boleslav. This facility also produced 349,021 MQ100 and MQ200 manual transmissions, 1,736,815 axles and 469,935 EA211 engines, which are also installed in other Volkswagen Group brands’ vehicles. Additionally, the site manufactured 165,606 battery systems for MEB vehicles and 147,625 battery systems for plug-in hybrid models. With a second assembly line commissioned in December 2023, the facility’s capacity is set to increase by 50% to 1,500 units a day.

The Kvasiny plant also contributed significantly, producing a total of 225,000 units of the Karoq, Kodiaq, Superb, and Superb iV models in 2023. Key highlights of the year included the unveiling of the second-generation Kodiaq in October and the world premiere of the fourth-generation Superb in November. The brand’s ICE flagship will continue to be available in both hatchback and Combi estate body styles.

In Vrchlabí, Škoda Auto’s production focused on DQ200 automatic direct-shift transmissions, with a total of 686,066 units manufactured. These transmissions are integral not only to Škoda’s models but also to vehicles across the Volkswagen Group.

International production facilities

At the Volkswagen facility in Bratislava, Škoda Auto’s production included over 36,000 units of the Karoq SUV and the initial units of the new Superb generation. The company was responsible for the entire development of both the Škoda Superb and Volkswagen Passat, which are manufactured on the same production line in Bratislava. This initiative is part of the Beta+ project, aimed at leveraging synergies in the production network and further boosting efficiency. By transferring the production of the Superb to Bratislava, the carmaker is creating capacity for additional units of the Octavia at the Kvasiny plant from the summer of 2024 onwards. Additionally, the move will allow more battery-electric vehicles to be built at the Mladá Boleslav plant.

At the Ukrainian plant in Solomonovo, 2,580 Škoda cars were assembled last year from semi-knocked-down (SKD) kits imported from Czech production plants. The potential for increasing production volumes at the Solomonovo facility is contingent on the evolving war situation in Ukraine.

Across the four Chinese factories in Changsha (Kodiaq and Kodiaq GT), Nanjing (Kamiq, Kamiq GT and Superb), Ningbo (Octavia, Octavia Pro and Karoq) and Yizheng (Rapid), the Czech car manufacturer built approximately 18,500 vehicles in 2023.

Internationalisation strategy: entering new markets and building synergies

Škoda Auto effectively advanced its internationalisation strategy throughout 2023. The Pune factory in India produced almost 48,000 units of the locally developed Kushaq and Slavia models. Additionally, the Aurangabad plant contributed approximately 4,400 units, encompassing the Superb, Octavia, and Kodiaq models. In total, Škoda Auto’s Indian facilities produced over 52,000 vehicles.

The company is actively seeking to reach more customers in India while also expanding its international market presence. In line with this objective, Škoda Auto opened a new Parts Expedition Centre in Pune in October 2023. This will serve as a logistics hub for completely-knocked-down (CKD) kits of the Kushaq and Slavia models manufactured in India, starting this year.

In December last year, the Indian Parts Expedition Centre achieved a significant milestone by being the first in India to receive the Indian Green Building Council’s platinum certificate for green building. The certification underscores the facility’s adherence to green building principles, focusing on water conservation, energy efficiency, natural resource preservation, waste reduction, and creating healthier spaces for workers. These efforts align with Škoda Auto’s corporate strategy for a sustainable future.

From Pune, the CKD kits are set to be exported to Vietnam, reflecting Škoda Auto’s expansion into that market in September 2023. Vietnam is part of the ASEAN region where Škoda Auto strategically leads the Brand Group Core and aims to maximise growth for the Volkswagen Group.

Škoda Auto’s re-entry into Kazakhstan in October 2023 marks another significant step in its internationalisation efforts, contributing to the company’s goal of expanding its global presence.

| Škoda Auto’s production in 2023 (*rounded figures) | |

| Vehicles | 888,000* |

| Engines | 469,935 |

| Axles | 1,736,355 |

| PHEV battery systems | 147,625 |

| MEB battery systems | 165,606 |

| Transmissions | 1,035,087 |

| DQ200 | 686,066 |

| MQ200, MQ100 | 349,021 |