Nov. 16, 2024

Toyota City, Japan, November 16, 2024―Toyota Motor Corporation (Toyota) will enter the ENEOS Super Taikyu Series 2024 Empowered by BRIDGESTONE Round 7 Super Taikyu Final Fuji, to be held from November 16 to 17, with the #32 ORC ROOKIE GR Corolla H2 Concept, a hydrogen-powered GR Corolla running on liquid hydrogen.

Toyota will also be exhibiting a concept model that envisions the use of boil-off gas* generated while driving as it looks for partners to take on the challenge of developing the technology together.

| * |

|

|---|

- Liquid hydrogen-powered GR Corolla

Forming partnerships to take on the challenge of using boil-off gas generated while driving

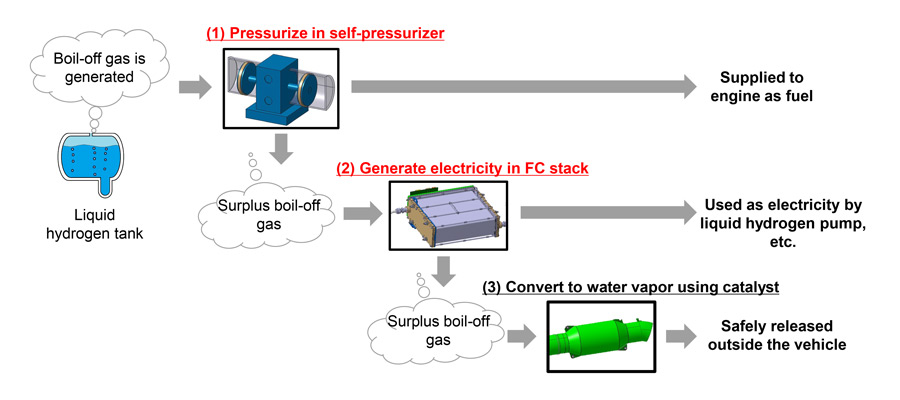

Liquid hydrogen has a higher density than gaseous hydrogen. This allows for more hydrogen to be stored in a tank of the same capacity but presents an issue of boil-off. This is a problem for all liquid hydrogen systems, where the liquid hydrogen fuel stored in the tank evaporates due to natural heat that enters from outside. Until now, the boil-off gas (vaporized hydrogen) generated in the fuel tank while driving has been released into the atmosphere without being used.

At the Super Taikyu Final Fuji, Toyota will exhibit a new concept model that utilizes the boil-off gas. Although it is still in the concept stage, if realized, this technology is expected to improve the energy efficiency of the entire liquid hydrogen system by recovering and using boil-off gas as energy. Thus, Toyota is looking to form partnerships that will help make this technology a reality.

- Overall image of boil-off gas utilization

- Reusing boil-off gas as fuel

Toyota is working on the development of technology to produce reusable fuel by sending boil-off gas released from liquid hydrogen in the tank to a self-pressurizer (a device that increases pressure without relying on external energy). Boil-off gas can be converted back to usable hydrogen fuel for the engine by applying pressure, but increasing the pressure sufficiently usually requires energy such as electricity. The self-pressurizer that will be exhibited at this event uses the pressure of the boil-off gas to increase pressure by two to four times and produce reusable fuel without using any additional energy.

- Self-pressurizer for increasing the pressure of boil-off gas (The meter on the left displays pressure after the increase, and the meter on the right displays pressure before the increase.)

- Generating electricity using boil-off gas

During the pressurization process for reusing boil-off gas (vaporized hydrogen), as in (1), a certain amount of surplus boil-off gas is still released.

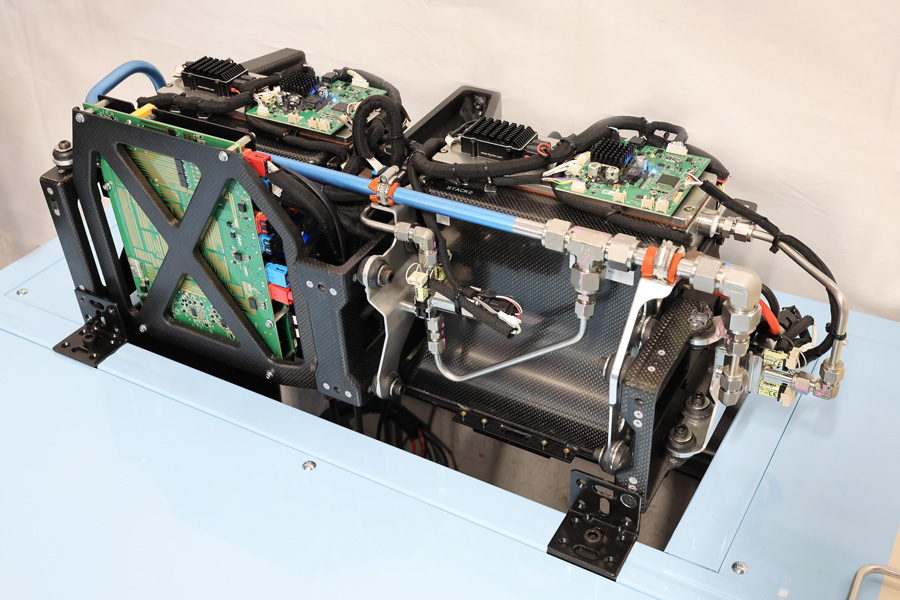

This is then fed into the small fuel cell package (FC stack) that Toyota has developed, and the hydrogen goes through a chemical reaction to generate electricity. The electricity generated can be used to power parts like the motor for the liquid hydrogen pump. If realized, it will be possible to supplement electricity equivalent to the amount generated by the alternator (small generator) from boil-off gas, leading to an improvement in energy efficiency.

- Small FC stack that generates electricity using boil-off gas

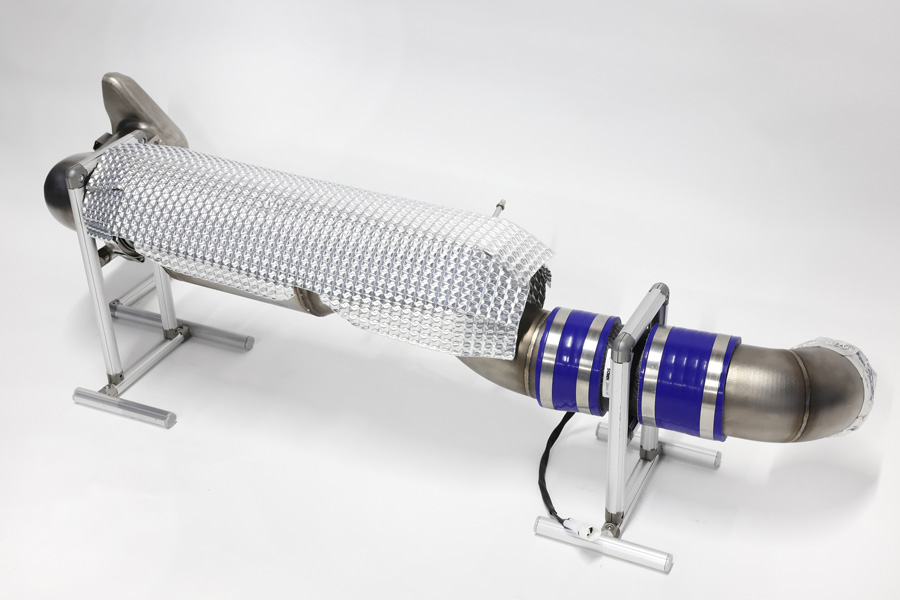

- Safely releasing surplus boil-off gas through catalyst

Boil-off gas that is not used in the electricity generation process in (2) is then converted into water vapor through a catalyst as before and safely released outside the vehicle.

- Catalyst to treat surplus boil-off gas

Toyota will continue to refine cars and people in the challenging world of motorsports and evolve together with its partners to achieve carbon neutrality.

“Achieving zero, and adding new value beyond it”

As part of efforts to pass our beautiful “Home Planet” to the next generation, Toyota has identified and is helping to solve issues faced by individuals and overall society, which Toyota calls “Achieving Zero,” hoping to help reduce the negative impacts caused by these issues to people and the environment to zero. Additionally, Toyota is also looking “Beyond Zero” to create and provide greater value by continuing to diligently seek ways to improve lives and society for the future.

- About Beyond Zero

- https://global.toyota/en/mobility/beyond-zero/

Toyota Motor Corporation works to develop and manufacture innovative, safe and high-quality products and services that create happiness by providing mobility for all. We believe that true achievement comes from supporting our customers, partners, employees, and the communities in which we operate. Since our founding over 80 years ago in 1937, we have applied our Guiding Principles in pursuit of a safer, greener and more inclusive society. Today, as we transform into a mobility company developing connected, automated, shared and electrified technologies, we also remain true to our Guiding Principles and many of the United Nations’ Sustainable Development Goals to help realize an ever-better world, where everyone is free to move.

- SDGs Initiatives

- https://global.toyota/en/sustainability/sdgs/