There are also design benefits from the CFRP.

You can already pre-order Polestar’s first-ever production vehicle, the Polestar 1 hybrid coupe, with a refundable $2,500 deposit (€2,500 or ¥20,000, depending on the market). However, the vehicle is not slated to arrive in showrooms before next year, so meanwhile the automaker wants to give you some more information about its product.

The Swedish company is happy to announce the construction of the Polestar 1 uses extensively Carbon Fiber Reinforced Polymer (CFRP), which brings a number of advantages. First, the coupe is some 500 pounds (226 kilograms) lighter than if it was using an equivalent steel-made chassis. Second, and probably most important, Polestar says that several main body panels are constructed from this lightweight material, making it a core contributor to the dynamic handling of the vehicle.

Learn more about the Polestar 1:

The Polestar 1 is actually the first model from Volvo ever to feature carbon fiber details, including hood, trunk, side body panels, doors, and the entire roof structure. The brand is so proud of that fact that it says it “acts as a technology spearhead for the Group.”

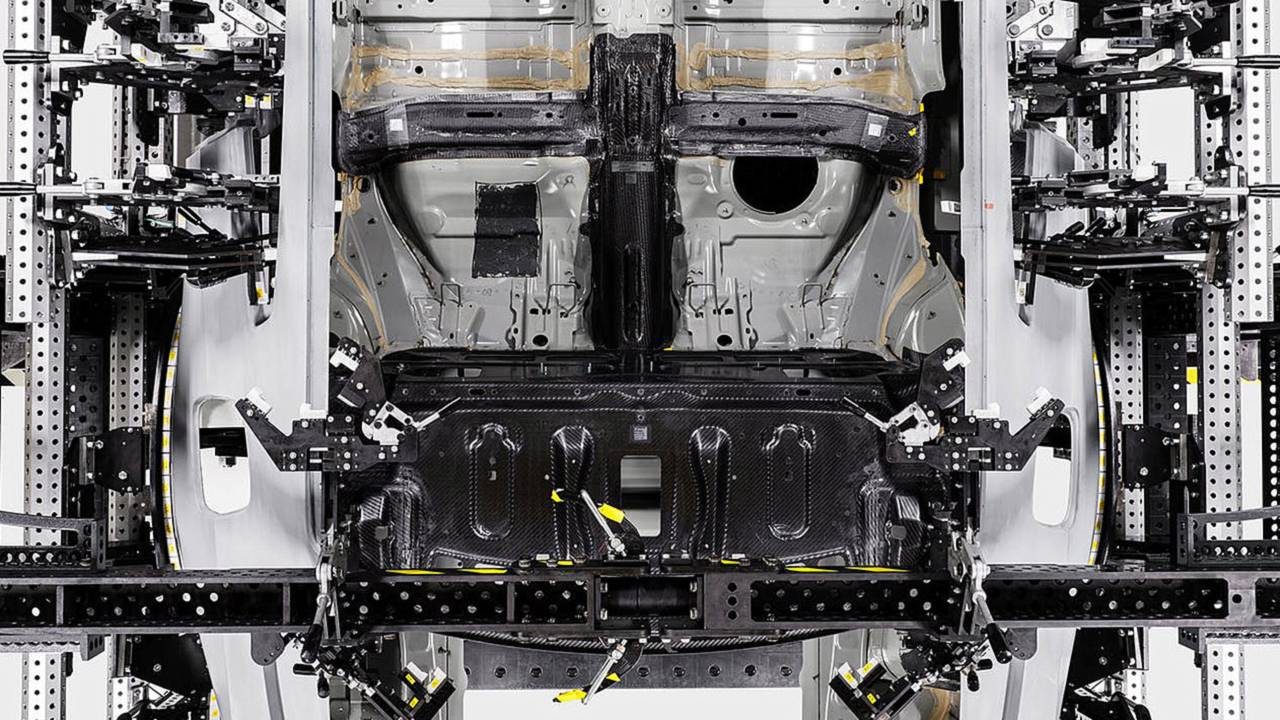

“The Polestar 1 features a structural ‘dragonfly’, which is also made from CFRP,” explains Christian Samson, head of product creation at Polestar. According to the company, this component radically improves the coupe’s torsional stiffness between the middle of the floor and front-rear construction, one of the critical points in the body structure.

On the other hand, the use of carbon fiber in the roof allows for a sleeker profile thanks to its thinner and stronger construction than a steel equivalent. A glass panel stretches the length and width of the roof, integrated with minimal intrusion from body elements on the inside for a truly panoramic view.

To be able to produce the Polestar 1 with all its CFRP components, the company is currently tooling specifically its Polestar Production Center, which is under construction and should be operational by mid-2019, to the needs of the coupe.

Source: Polestar

Polestar 1 carbon fiber construction

Hide press releaseShow press release

Carbon fiber plays integral role in Polestar 1 development

One of the key components in creating a responsive and agile driving experience in the new Polestar 1 is the extensive use of Carbon Fiber Reinforced Polymer (CFRP). Producing an overall weight savings of more than 500lbs versus steel. Most of the main body panels are constructed from this high-tech and lightweight material, making it a core contributor to the dynamic handling of the Polestar 1.

The Polestar 1’s carbon fiber body represents the first time that the Volvo Car Group has explored carbon fiber construction – an example of how Polestar acts as a technology spearhead for the Group. The Polestar Production Center, which is currently under construction and due to begin full-scale production in mid-2019, is being specifically tooled to deal with the intricate nature of carbon fiber construction.

Carbon fiber components have been used extensively in the car’s structure, including the hood, trunk, side body panels, doors and the entire roof structure. “The Polestar 1 features a structural ‘dragonfly’, which is also made from CFRP,” says Christian Samson, Head of Product Creation at Polestar.

The dragonfly-shaped component plays an instrumental role in creating the Polestar 1’s reactive dynamics – it radically improves torsional stiffness at one of the critical points in the body structure, between the middle of the floor and front-rear construction.

“When you combine this strengthened framework with the super-strong body and roof structure, you get a stiff and communicative chassis which translates driver input into superb driving characteristics,” continued Samson.

There are significant design benefits as well. The carbon fiber roof structure is not only thinner and stronger than a steel equivalent, but it also allows for a much lower roof line, resulting in a sleek and slender profile. A glass panel stretches the length and width of the roof, integrated with minimal intrusion from body elements on the inside for a truly panoramic view.

Thomas Ingenlath, Chief Executive Officer at Polestar, concludes: “Carbon fiber is crucial in meeting our design, engineering and performance goals with the Polestar 1. The result is a beautiful, technological package that remains faithful to the original design with its elegant and low silhouette. It looks as good as it is to drive!”