*/

]]>

Rüsselsheim TechDay (11-14 June 2018): Around 240 journalists, financial analysts, suppliers, dealers, politicians and employees will learn the key role of the Rüsselsheim Research and Development Center in the global engineering network of Groupe PSA.

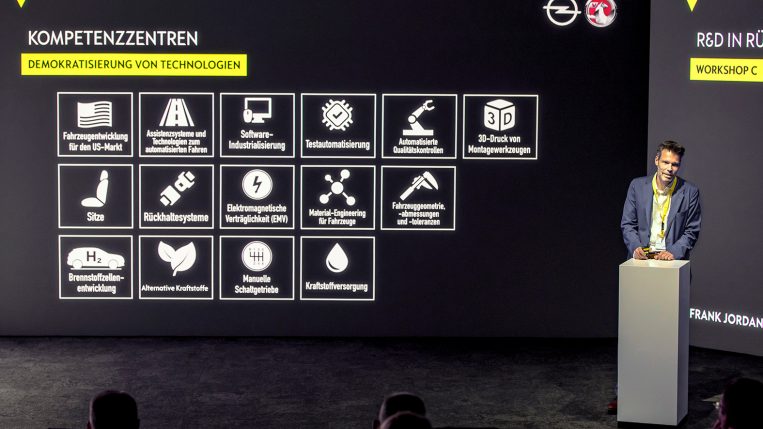

Rüsselsheim TechDay: Relaxed semi-darkness, comfortable armchairs, a gigantic screen. The Virtual Reality Room of the Design Center is a cinema atmosphere. The title of the exclusive trailer is “Research & Development in Rüsselsheim for the entire Groupe PSA”. In the lead roles: fuel cells, test automation and seat designs. Because colleagues from the Development Center use the event to show journalists, dealers and employees what Opel’s key role within the Groupe PSA is. That means an hour full of information, lectures, charts and videos. The message: “Our Engineering Center brings typical Opel strengths to the company’s global development network,” said Frank Jordan, Director of Innovation & Advanced Engineering, citing a total of 15 so-called Centers of Competence (CoC) located at the headquarters. “This benefits the entire Groupe PSA.”

![]()

“Every brand within Groupe PSA has its own customer profiles. One thing is clear: an Opel will always remain an Opel. “

– Frank Jordan –

![]()

Possible competition with regard to the other Group brands Peugeot, Citroën and DS Automobiles sees Jordan none. “Each brand has its own customer profiles, and we complement the French brands very well. One thing is clear: an Opel will always remain an Opel, “he explains. The Rüsselsheim Development Center guarantees for Opel the combination of German engineering, precision and innovation that the customer can afford.

Bundled know-how: Frank Jordan explains which 15 competence centers are based at the Opel headquarters in Rüsselsheim.

Stefan Koob, Senior Development Manager Seat Development, heads the Seat of Competence Center.

As one of the 15 competence centers, the seat development in the Engineering Center will be responsible for all seats of Groupe PSA. Stefan Koob, head of the CoC in Rüsselsheim, emphasizes the Rüsselsheim know-how acquired through, among other things, decades of development work for the US market. “The establishment of the competence center in Rüsselsheim is therefore a logical step,” says senior manager Seat Development, which calls flexibility and comfort the key strengths of the Opel seats.

![]()

“Whether Peugeot, Citroën, DS Automobiles, Vauxhall or Opel – the seats come from Rüsselsheim, but of course each brand retains its own DNA seat.”

– Stefan Koob –

![]()

Meanwhile, the biggest challenge for Rüsselsheim’s development expertise lies in the specifics of Peugeot, Citroën and DS Automobiles. “In general, of course, we want to maintain the DNA of all Groupe PSA brands, as each customer should continue to recognize the typical car seat. Customer satisfaction is our top priority. “

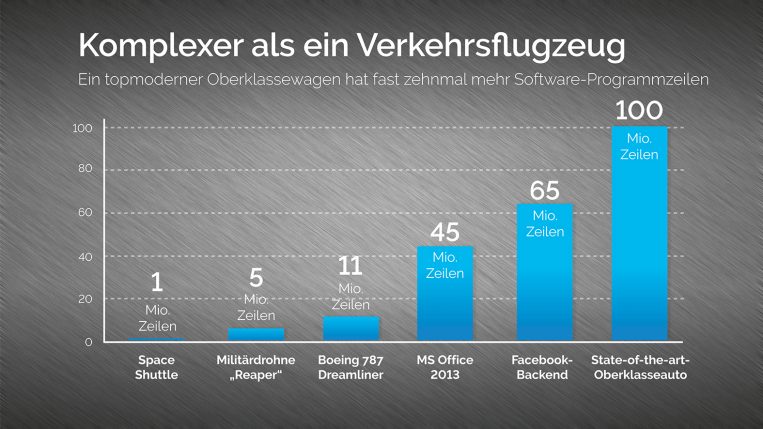

“There are ten times more software program lines in a state-of-the-art luxury class car than in a commercial aircraft,” says Dr. Marco Moebus, Manager Business Support Engineering. Thus, it is no wonder that traditional development concepts have long reached their limits. The CoC for test automation in Rüsselsheim is therefore developing innovative validation methods in three major areas: autonomous driving, connectivity and the interface between man and machine. To shorten development times, Rüsselsheim, for example, is already testing automated infotainment systems overnight or over the weekend.

![]()

“An automated car has to be better than the human.”

– Dr. Marco Moebus –

![]()

And on the way to autonomous driving, there is no way around new validation methods anyway. Too large are the amounts of data that must be captured and evaluated. To achieve sufficient statistical significance for highway automation alone, 120 million (!) Test kilometers are needed. An effort that would be repeated for every new function – if only a new sensor technology. And then there are also rural roads. And the city traffic. Amongst other things. Without innovative validation concepts there would be no autonomous driving, so Moebus. “Because an automated driving car must be better than the human being”, as Moebus emphasizes. “We have to be able to trust the vehicle. Because who would let his children ride with an insecure driver? “

Dr. At the TechDay 2018, Marco Moebus explains the tasks of the CoC for test automation.

↑ Video: Research & Development in Rüselsheim for the entire Groupe PSA

Confronting pros and cons: dr. Lars Peter Thiesen talks about the tradition and future of fuel cell technology at Opel at TechDay 2018.

Finally, Dr. med. Lars Peter Thiesen the tradition of fuel cells at Opel. First, the manager of Advanced Technology Integration explains the technology: Refueled, highly compressed hydrogen (H2) generates with the oxygen (O) from the ambient air at about 80 degrees Celsius in electricity, which then drives the electric motor of the car. Water vapor (H2O) finally comes out as the only product from the exhaust. “Of course this is a very clean solution,” says Thiesen. The new Competence Center “Hydrogen & Fuel Cell” in Rüsselsheim can build on many years of Opel experience in this area, as Thiesen further explains. Because: Opel operated from 1997 to 2012, an alternative Propulsion Center in Mainz-Kastel. Here, in the immediate vicinity of Rüsselsheim, 250 experts researched and developed electric drives and fuel cell technology.

![]()

“In terms of performance and reliability, a fuel cell vehicle is comparable to a normal car.”

– Dr. Lars Peter Thiesen –

![]()

For most of the once-open questions – such as the duration of refueling, range and access to gas stations – have long since found answers. “In terms of performance and reliability, a fuel cell vehicle is comparable to a normal car. Even starting at minus 20 degrees is no problem and refueling takes only three minutes, “explains Thiesen. “In addition, the plants are internationally standardized and can be reached at any time.” The costs and expansion of the hydrogen infrastructure are the remaining major challenges of this technology. However, more than 20 years after the beginning of the research work, which ultimately resulted in three vehicle generations, Opel has a broad expertise in this field. “We want to build on that.”

Digitalization sends greetings: The complexity of a system or product can be read off software program lines – and the car ranks first in this ranking.

As of June 2018

Photos and graphics: Opel