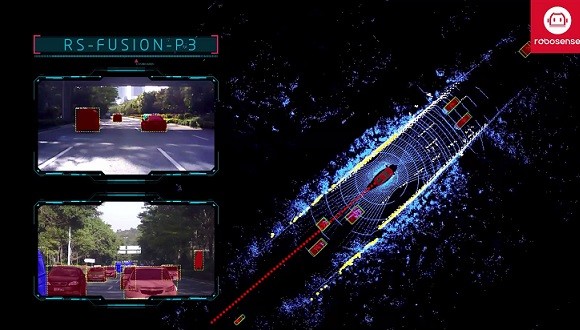

IMAGE: The solid-state MEMS-based RoboSense lidar system is dramatically cheaper than mechanical designs with high-performance specifications. (Image credit: RoboSense)

Light detection and ranging (lidar) company RoboSense (Shenzhen, China; http://www.robosense.ai) launched its RS-IPLS Intelligent perception lidar system, calling it the first hardware and software algorithm based solution for the mass production of safer autonomous cars. An autonomous driving system, the RS-IPLS features real-time data pre-processing and a “gaze” function similar to human eyes. The RoboSense system is inexpensive–1/400th the price of traditional 64-line lidar systems and is designed for the mass production of vehicles at a low price.

Based on MEMS solid-state lidar, the system outputs the highest resolution color point cloud data by merging the underlying hardware of 2D imagery with the unique RoboSense RS-LiDAR-Algorithm deep learning sensing algorithm developed specifically for autonomous driving. The intelligent detection algorithm achieves object level information that adjusts the Region of Interest (ROI) detection area in real time with no delay.

[Native Advertisement]

The RS-IPLS features the new RoboSense RS-LiDAR-Gaze “Gaze” Technology. When the system perceives a target of interest in its field of view, it initiates a “gaze” processing mechanism that instantly locks the target for ROI processing, thus achieving the clearest and most stable environmental data. The lidar low level architecture maintains a high degree of vigilance of the surrounding environment, constantly capturing the areas of interest, allowing the “gaze” to transfer efficient and high-quality feedback in the field of view.

The RoboSense RS-IPLS Intelligent Perception lidar system also provides richer three-dimensional spatial data information (X, Y, Z, R, G, B) in real-time from the bottom layer, which reduces the time delay normally caused by external fusion. Data pre-processing is performed by the AI algorithm, with the region of interest repeatedly detected for farther detection distance and more accurate perception results for autonomous driving, with reduced data processing stress to the central data processing unit.

“LiDAR needs a self-revolution. The market needs an automotive-grade product that can be mass produced in the tens and hundreds of thousands. You have to guarantee low cost and provide high performance to ensure the safety of your vehicle,” said Mark Qiu, RoboSense co-founder. “This has driven us to create a whole new sensor system technology based on the perfect extraction of environmental information and large-scale perception of the environment, with the constant capture of areas of interest, focusing on effective information.”

Automated driving has almost the same long history as the automobile manufacturing industry. In 1913, Ford developed a production line for the mass production of cars. At the same time that carriages were replaced by cars, people began to imagine autonomous driving. In 1925, the American team of Francis P. Houdina developed the first “driverless car.” Over the past decade or so, the emergence of mechanical multi-line LiDAR has solved the problem of high-precision 3D environment perception, and the autonomous driving industrybxtcerzyuqtefq has entered a period of growth.

RoboSense’s mass production price of the RS-IPLS is only $200–1/400th of the traditional 64-line LiDAR, with a several thousand or even tens of thousands faster response speed. Traditional mechanical LiDAR consists of multiple sets of transmitters, receivers, precision optics, micro-control motors, and other components, which are difficult to manufacture and require expensive materials. In addition, due to difficulty of integration and optics, mechanical LiDAR not only has a long production cycle and high production costs, but also has a difficult time meeting the stability and reliability requirements of standard vehicles. Because of these reasons, traditional mechanical LiDAR technology has become inadequate.

“The new RoboSense RS-IPLS MEMS based technology is intelligent, accurate, lower cost, and faster–and is poised to take over the market,” concluded RoboSense’s Mark Qiu.

SOURCE: RoboSense via Thomas PR; http://www.thomas-pr.com/robosense/robosensersiplsrelease.html