- First electric central drive with functional safety for buses and medium-duty trucks developed for the Chinese market

- Unit strengthens ZF presence in this important market

- 100 percent of volume production will be in China

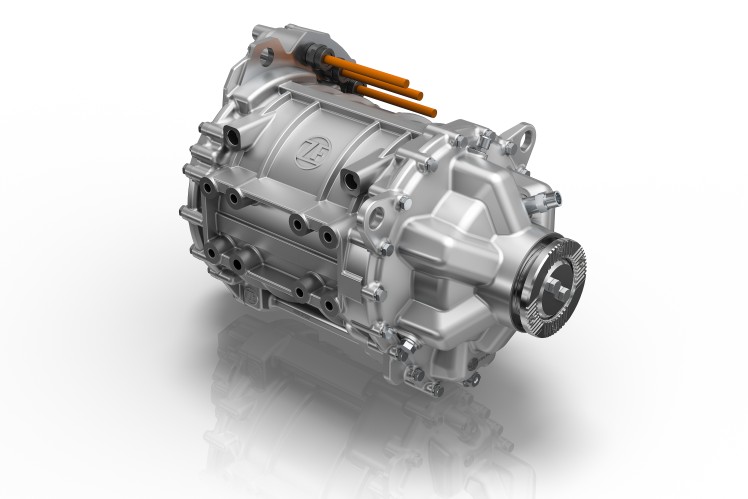

Friedrichshafen/Shanghai. Against a backdrop of exhaust pollution in China’s cities, the country’s commitment to electromobility is probably greater than that of any other country. The electrification of public transport and distribution logistics plays an important role in satisfying this commitment. ZF is supporting China’s efforts with supply of a new electric central drive for buses and medium-duty trucks. Developed in China, with future production planned there, the new unit is designed to meet the particular conditions of the Chinese market and the requirements of vehicle manufacturers there.

The new electric central drive was developed by a local ZF development team to meet the specific requirements of the Chinese market in terms of safety, performance and cost-effectiveness. Designed for city and shuttle buses with a length of 10~12 meters as well as medium-duty trucks up to 12 tons, it meets all the necessary standards for integration into established vehicle platforms.

Powerful thanks to permanent magnet

The unit is driven by a permanent magnet synchronous motor (PSM). As a permanent magnet motor, it is highly efficient even at low speed range, making it particularly suitable for stop-go traffic typical of urban areas, while enabling greater range per battery charge. With an output of 170 kW, peak torque of 3000 Nm and a maximum climbing capacity of approx. 15 percent (bus) or 25 percent (truck), demanding topographies are no problem for the new drive. Production is expected to start in China next year, which will ensure rapid availability to the market.

First system with functional safety in China

In addition to the unit itself, ZF will also be able to supply inverters and control units including the appropriate software. This guarantees optimum efficiency between battery and drive and reduces testing and homologation costs for the manufacturer. Thanks to ZF software competence, the drivetrain control unit offers comprehensive additional functionalities and ensures a higher safety level compared to other solutions on the market. The system is designed to fulfill international functional safety standard (ISO26262) with level at ASIL-C.