The world’s first cars to use recycled cobalt whose supply chain is tracked on Blockchain has been produced by Volvo.

The global car maker that is owned by a Chinese firm – Geely used recycled cobalt. This strategy could guarantee the brand a positive reception in a market that is becoming more concerned and involved in sustainable means of production.

Further, Volvo has joined a separate project that traces cobalt from the Democratic Republic of Congo (DRC). The mission of the project is to offer reliable data to consumers to shun out unethically produced minerals.

Improving Accountability Of Supply Chain

In an email that Volvo sent out on Friday, the team revealed that they had completed the pioneer Blockchain program. This new adoption case marks yet another milestone in the adoption of DLT across the broader industrial spectrum.

In the project, the platform monitored the supply chain of the recycled cobalt right from the recycling plant to Volvo cars plant in Zhejiang. The period timeline span two months and the company is optimistic that the project is proffering next-level “transparency and traceability”. Openness is fundamental in improving the accountability of the supply chain for intermediate car products.

About The Blockchain Platform

Interestingly, the adoption of Blockchain technology is very dynamic as traditional technologies such as Oracle and IBM are increasingly creating hybrid platforms powered by Blockchain.

In this use case, the platform has been developed by a UK-based Blockchain specialist known as Circulor. The Circulor Blockchain experts used technology from Oracle to design the software to perfection. In the design, Blockchain technology guarantees security through immutability, decentralization, and security.

It is widely expected that the platform would be deployed in 2019, but Volvo is yet to give out any official statement.

In the meantime, Contemporary Amperex Technology is producing the batteries for Volvo cars.

Volvo Is Now A Member Of The Responsible-Sourcing Group RCS Global

The Responsible-Sourcing Group RCS Global is an organization with a mission of improving transparency in supply chains. Volvo, alongside Huayou Cobalt, South Korea-based cathode maker LG Chem, Ford Auto Makers, and IBM technologies, is part of the RCS Global project.

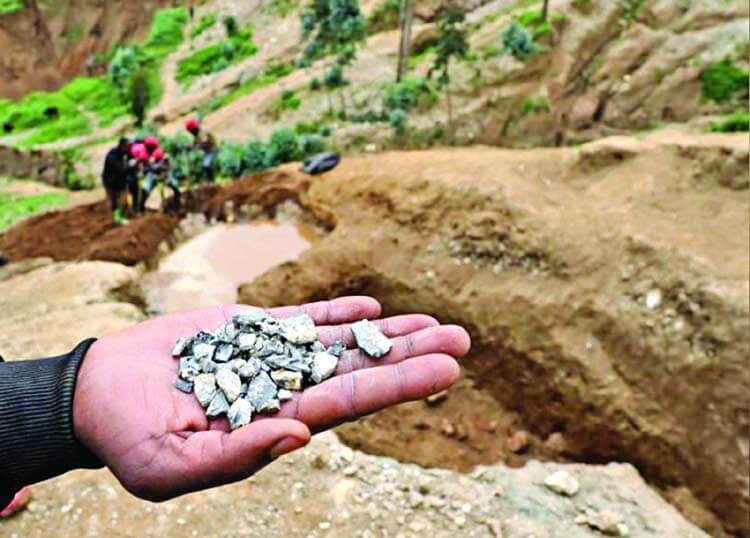

The project aims to sanitize cobalt production and its supply chain. The industry is marred by rampant cases of unethical means of extraction and production characterized by claims of child labour, meagre wages for miners, conflict financing, etc.

Notably, the DRC supplies 75% of the global Cobalt supply, where the Felix Tsishekedi-led government is largely inept and almost non-existing, especially in the vast equatorial rural areas.

Is Blockchain The Answer To Transparency?

Although experts differ on whether the exclusive use of DLT is the key to tracking minerals, some quarters say that the technology could play a critical role in improving accountability is supply chain participants enter accurate data on each stage of production and supply.

The CEO of Circulor Doug Johnson-Poensgen, on his part, believes that due diligence cannot be replaced by technology. However, DLT has the potential to “improve enforcement of standards” by highlighting areas of inconsistencies and irregularities in supply chains.