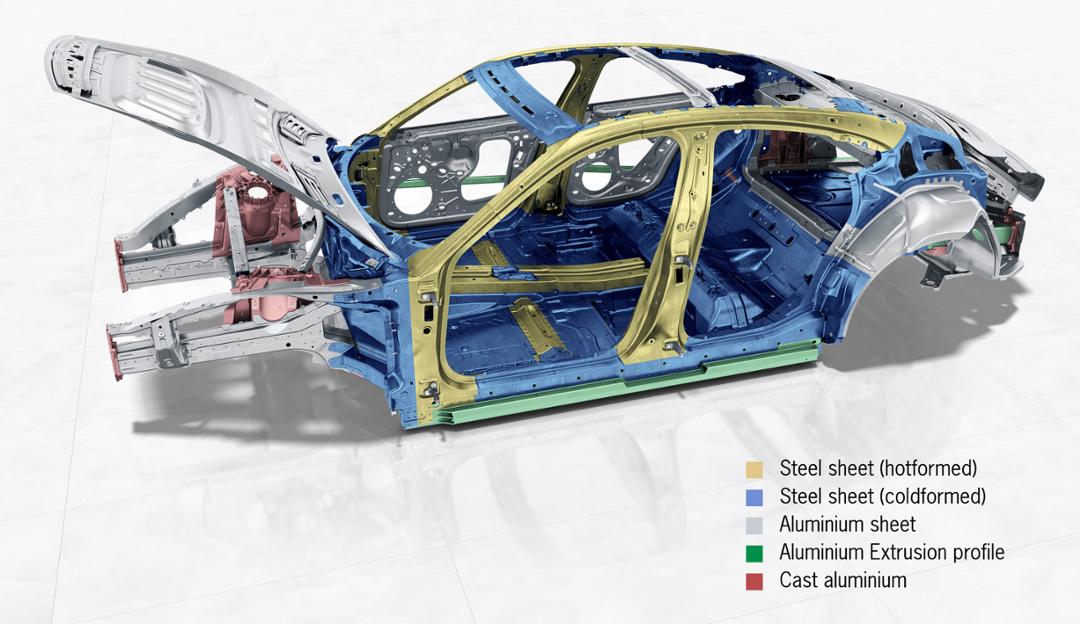

The strut mounts, axle mounts and the rear side members are made of die-cast aluminium. The shock absorber mounts are forged aluminium. The front side members combine an aluminium shell construction with extruded sections. The 1,941-millimetre sills are designed as seven-chamber extruded sections. Compared to steel sills, this reduces the number of components per side from 15 to three and the weight by around 3.4 kilograms.

Hot-formed steels protect the passenger compartment (A-pillar structure, B-pillar inside/outside, side roof frame, seat cross member). A special highlight is the bulkhead cross member, which is manganese-boron steel. Special manufacturing processes are used to produce various cross-sections within the tubular component. This results in maximum strength with optimised weight. Apart from the front and rear end components, the complete outer skin is made from aluminium. With a draw depth of 325 millimetres, the one-piece aluminium side panel posed a particular challenge for development and production. The total aluminium content for the Taycan is around 37 percent.

The low central installation position of the Performance Battery Plus ensures a very low centre of gravity. Its integration was an essential cornerstone in the design of the body. The aluminium housing of the underfloor battery was designed as a load-carrying component and forms part of the Taycan’s safety structure. A total of 28 bolts are used to attach the housing to the body.

“Foot garages” – recesses in the battery in the rear footwell – provide improved rear seating comfort, while at the same time allowing for the low car height and flyline that are so distinctive in sports cars. The result is a low seating position and sufficient head clearance at the rear, despite the underfloor battery. Two luggage compartments are available: The front compartment has a capacity of 81 litres, and the rear 366 litres.

The panoramic fixed glass roof: a clear view without distracting roof bows

Due to its flat construction, the panoramic fixed glass roof blends harmoniously into the silhouette. Transverse bows were not required. This means the continuous area of the roof in the new Taycan measures one square metre, and as such provides an even more pleasant feeling of space and airiness. It is also possible to use a Porsche roof transport system.

For the first time in a Porsche, low-emissivity thermal insulation glass is used for the panoramic fixed glass roof. Several wafer-thin metal layers are applied to the insulating glass. As the thermal insulation glass allows short-wave radiation to pass through and reflects long-wave infra-red radiation, the vehicle interior will heat up more slowly in summer. This also means that the heat in the interior is retained longer in winter. In combination with the glass tint, it was therefore possible to dispense with a roller blind. An intermediate layer in the glass structure also provides acoustic insulation for the interior.

Additional content

Sports cars, redesigned with sustainability in mind. The first all-electric sports car, the Taycan, marks the beginning of a new era for Porsche as the company systematically expands its product range in the field of e-mobility. An overview.