- First fully integrated electric axle drive system enters volume production in China and Europe

- Innovative third-generation electric drive system offers outstanding power density

- Vitesco Technologies’ portfolio focused strongly on electrification and electric mobility

Regensburg, October 9, 2019. Vitesco Technologies, the former Powertrain division of Continental, today announced it has signed agreements with Groupe PSA and Hyundai to supply the first fully integrated electric axle drive system for various volume-production models. The agreement with two leading OEMs highlights Vitesco Technologies’ position as a pioneer of intelligent customized solutions for all electrification aspects. Production of the new electric drive system at Vitesco Technologies plant in Tianjin, China, has already started.

“I am very excited to announce that two leading vehicle manufacturers have chosen Vitesco Technologies’ – to produce innovative electric drive unit to power their electric volume-production models,” said Andreas Wolf, CEO of Vitesco Technologies. “Our new integrated axle drive unit and our extensive experience in electrifying drive-units have made Vitesco Technologies the partner of choice for carmakers striving to be at the forefront of e-mobility.”

First fully integrated electric axle drive system for various volume-production models of PSA and Hyundai

Groupe PSA has selected Vitesco Technologies’ new electric drive system for its e-CMP modular electric platform, which compact battery electric vehicle models such as the Peugeot e-208 and Opel Corsa-e will be built on. The Hyundai Motor Corporation has made Vitesco Technologies the supplier of choice in China through its joint venture Beijing Hyundai. Two models will be equipped with Vitesco Technologies’ electric drive system: the Encino compact SUV and the Lafesta sedan. In addition, other vehicle manufacturers have chosen Vitesco Technologies to supply drive systems for battery electric cars that are planned to launch over the next 12 months. The innovative electric axle drive system will also power German start-up Sono Motors’ Sion battery electric vehicle. “Electric vehicles are starting to go mainstream – with our sophisticated technology on board”, Wolf said.

Long-standing focus on powertrain electrification

Vitesco Technologies’ electrification track record of more than a decade makes the company a key partner to all major car manufacturers. The company’s long-standing and enduring commitment to pioneering electric mobility solutions started back in 2006. By 2011, this electric drive system was on the market – in the Renault car models Zoe, Fluence and Kangoo. Now, Vitesco Technologies has used its experience and deep expertise in electric drive systems to bring its innovative third generation of its electric axle drive system to market.

Two power ratings and best-in-class power density, size and weight

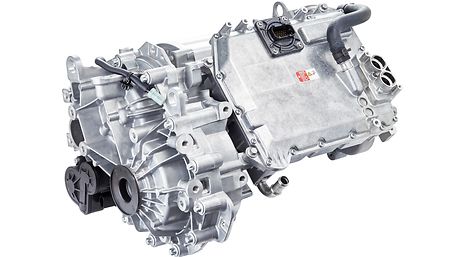

Based on their expertise in systems and electronics, Vitesco Technologies’ engineers have improved the interaction between the system’s individual components: electric motor, power electronics and transmission. These improvements result in a drive system that is lighter, more compact and cost-effective. The new module – whose electric motor and power electronics are liquid-cooled – weighs less than 80 kilograms. It also features a new transmission-integrated electric parking lock function. Through the intelligent combination and integration of the system’s individual components, it was also possible to remove numerous connectors and cables, cutting costs even further.

“We offer our highly integrated electric axle drive system in power ratings from100 up to 150 kW,” said Thomas Stierle, Head of the Hybrid Electric Vehicle business unit at Vitesco Technologies. “With a maximum output of 150 kW and maximum torque of 310 Nm, the more powerful version is comparable with a conventional 2-liter turbodiesel engine, offering best-in-class power density, size and weight,” he added.

Portfolio focused strongly on electrification and electric mobility

Focus on electrified and all-electric technologies

Vitesco Technologies chose to build this new electric axle drive system in China, currently the world’s largest and fastest-growing market for electric vehicles, and near its customers. This will enable Vitesco Technologies not only to serve its customers better, but also to showcase the Tianjin plant’s experience in the field of electric drive technologies. Highly automated production lines at the plant allow for large production volumes to be built to the highest quality standards.

Today, Vitesco Technologies is one of the few automotive systems suppliers to offer complete electrification systems from a single source. The company’s portfolio ranges from 48-volt electrification technologies and key components for hybrid drives to full battery-electric drive systems.

“We will be focusing our investment strategy even more heavily on electrified and all-electric technologies and channeling more internal resources into these areas. In doing so, we are significantly strengthening our existing high level of electronics expertise,” Wolf explained.