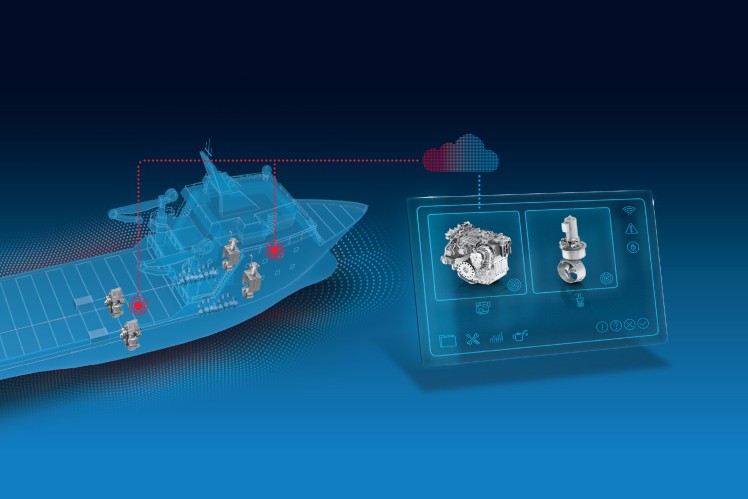

New Orleans. A global specialist for marine propulsion systems, ZF has introduced an intelligent Condition Monitoring System for thrusters. The technology monitors the status of the thruster system and helps shipyards, shipping companies and fleet operators maintain the safety and efficiency of their ships as well as extend the service life of the propulsion system. In addition to that, a new oil cleaning system ensures oil quality and prolongs oil service life.

ZF’s Condition Monitoring System is equipped with various sensors and an intelligent electronic evaluation unit. This system measures vibrations which indicate the condition of the bearings and gears in the thruster’s upper and lower gearbox. The measurement results help the operators identify early on which components need to be replaced or maintained. This means repairs can be planned in advance and potential damage to components can be avoided, all of which prevents downtime and shortens maintenance cycles. It also extends the service life of the monitored systems and components, allowing the operators to focus on the job at hand.

“Particularly with biodegradable oil, it is important to keep contaminants, such as water, out of the system so as to prevent downtime caused by mechanical failure.” Said Drew Orvieto, Senior Manager, Commercial Fast Craft Product Line and Engineering North America.

By heating up the oil, the water is evaporated, a cotton element filters out particulate down to 1 μm. Clean oil is pumped back into the system which extends the service life of the oil by 10 to 15 times. In conclusion, fewer oil changes are required which decreases operating cost.