– Unlock software innovation to enable feature-rich and highly automated vehicles

– Reduce complexity, accelerating development and enabling manufacturing automation

– Unite diverse applications to provide new functionality and improve lifecycle management

LAS VEGAS, Jan. 7, 2020 /PRNewswire/ — Aptiv PLC (NYSE: APTV), a leading technology company committed to making mobility safer, greener, and more connected, unveiled today a modern, sustainable vehicle architecture that enables automakers to improve safety, increase vehicle efficiency, and deliver the intelligently connected, software-defined experiences consumers want.

Aptiv’s Smart Vehicle Architecture (SVA) debuts at the Consumer Electronics Show 2020 as today’s vehicle architectures have reached an impasse and are no longer able to handle the rapidly increasing software and hardware complexity of feature-rich and highly automated vehicles. At the same time, OEMs are making unprecedented investments in electrification, which SVA is ideally suited to support. The intersection of these trends – exponential increases in software-enabled functionality, vehicle electrification, and intelligent connectivity – will have a profound impact on the future of mobility and society.

“Automakers will need to adopt a new vehicle architecture to unlock software innovation and actually bring to market the innovative concepts on display across CES,” said Kevin Clark, President and Chief Executive Officer, Aptiv. “As a full systems solutions provider, uniquely positioned with both the brain and nervous system of the vehicle, we know that Smart Vehicle Architecture is the right approach to enable the future of mobility.”

Aptiv’s expertise in software and systems integration, combined with its ability to provide automotive-grade compute and signal and power distribution inside the vehicle, sets the company apart from others looking to help OEMs address vehicle electrical and electronics complexity. SVA is a sustainable open platform that lowers total cost of ownership and enables feature-rich, highly-automated vehicles. It is also built to meet the most stringent functional safety and cybersecurity standards. Additional benefits include:

- Unlocking New Software-Enabled Functionality Today’s vehicles are complex and costly to develop. SVA’s intelligent abstraction, standardized interfaces, and scalable compute lower costs by allowing software applications to be developed independent of the hardware and reused across platforms, providing scalability on the path towards full safety automation.

- Reducing Complexity. Many of today’s features are highly distributed among individual controllers. SVA drives significant consolidation by centralizing compute power into more manageable zone controllers, while also separating it from I/O to allow for the easy addition of features. The zone controllers provide an interface to the sensors, manage the power, and provide compute functionality inside the zones that can be used for feature consolidation. For central compute, SVA’s Open Server Platform can dynamically allocate computing resources to both safety-critical, and non-critical functions, providing maximum performance and flexibility while optimizing cost. These changes reduce weight and packaging space for compute by 25%.

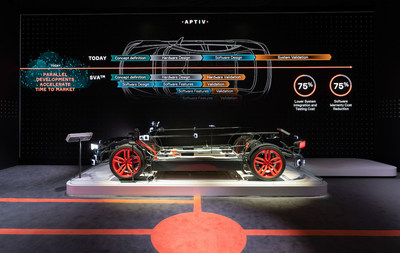

- Accelerating Development Cycles. Current development, test, and validation processes must be done sequentially. SVA’s abstraction of software from hardware and separation of I/O from compute enables independent parallel development cycles, shortening time to market and allowing for significant software reuse. The company expects SVA to reduce system integration and testing costs, as well as software-related warranty costs, by roughly 75% each, while making the need for model year updates a thing of the past.

- Providing Modular Architecture that Simplifies Manufacturing. Aptiv’s architecture is designed for the factory of the future, where automation will ensure quality and help lower costs. It’s modular zonal architecture with Dock & Lock™ connection system enables designs for simplified manufacturing and vehicle assembly, while common sub-assemblies result in 25% fewer SKUs. Additionally, Aptiv believes OEMs that adopt SVA will require 20% less factory floor space for assembly of the electrical architecture.

- Unlocking new business models. Aptiv’s server-based central compute, Aptiv Open Server Platform, supports over-the-air software and firmware updates, enables performance enhancements, and optimizes data analytics with edge compute. It also provides an open platform and development ecosystem to leverage third-party innovation.

Aptiv is displaying its Smart Vehicle Architecture and high-voltage electric vehicle solutions inside the company’s private pavilion at the Consumer Electronics Show 2020 in Las Vegas. In addition to SVA, the company will showcase advanced solutions designed to save lives today and in the future, efficiently meet environmental and security standards, and empower automakers to deliver the unique and differentiated user experiences that define their vehicles.

To learn more and see this innovation firsthand, please visit aptiv.com/CES2020.

About Aptiv

Aptiv is a global technology company that develops safer, greener and more connected solutions enabling the future of mobility. Visit aptiv.com.

![]() View original content to download multimedia:http://www.prnewswire.com/news-releases/aptiv-unveils-smart-vehicle-architecture-at-ces-2020-300983160.html

View original content to download multimedia:http://www.prnewswire.com/news-releases/aptiv-unveils-smart-vehicle-architecture-at-ces-2020-300983160.html

SOURCE Aptiv PLC