Cars are becoming lighter, safer, and more beautiful. Brand-new material is the key ingredient.

Cars are transforming from a simple means of transportation to a high-tech gadget. Automakers are using more innovative materials to make their cars faster, safer, and prettier every day. Plus, there are tighter environmental regulations and pickier consumers. Here are brand-new, innovative materials and manufacturing technologies out there in the automotive world.

Ultra-Low Specific Gravity Sealer for Lightweightness

The term ‘lightweight’ seems to have become ubiquitous in the recent discussions about automobiles. Hyundai/Kia’s lightweight technology can also be found in more subtle aspects of the car. One evidence of such is an ultra-low specific gravity sealer (ultralight adhesive) developed and mass-produced by the collaboration of the materials and production engineering departments. Sealers are adhesives applied between the panels to prevent rust and ensure water-tightness. In general, Approximately 8 kg is used for every car produced, which would amount to 170 m in length if placed in a horizontal line. New types of materials could do the trick here.

Hyundai/Kia solved the crux of the new ultra-low specific gravity sealer, through the cutting-edge lightweight material ‘glass bubble.’ Contrary to conventional materials, the glass bubble is a hollow ultralight material with a glass exterior layer and a vacuum interior (Microsphere). It is currently being used as a high-quality insulation filler material for fields such as construction and aircraft building. Thanks to the introduction of the glass bubble, sealer weight could be reduced by 37% or 3 kg per vehicle. This technology is widely used for various Hyundai and Kia models.

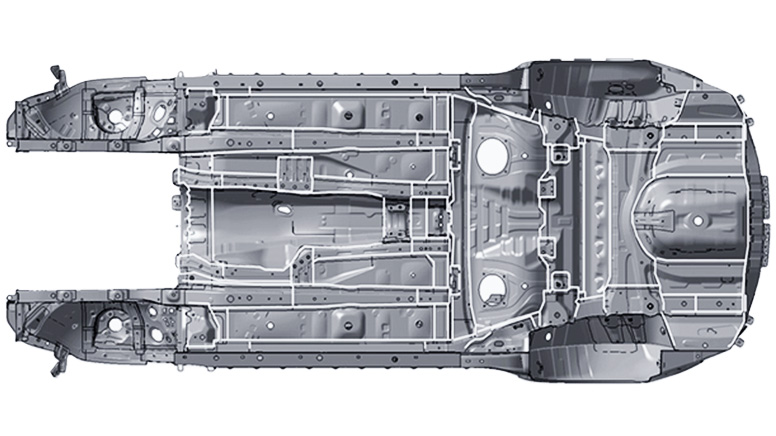

Lightweight and Sturdy At The Same Time: High-Strength Steel Sheets

The chassis of a car is like a bone structure of our body. A chassis is the basic framework of your vehicle, absorbing impacts and protecting passengers in a car crash. Being lightweight and sturdy are inversely proportional—but technology can solve this dilemma. Hyundai/Kia achieved a considerable decrease in curb weight by optimizing the structure and increasing the use of high-strength steel sheets.

The conventional high-strength steel sheets are strong enough, yet it meant it is also too hard to modify. However, Hyundai/Kia’s 3rd-generation steel sheet is 30% easier for modification. Hyundai/Kia is valiantly meeting the weight loss objectives, with tons of different materials – aluminum, synthetic resin, or thermoplastic composite material.

Carbon-Fiber-Reinforced Plastic In the Motorsports Industry

Lightweight yet durable materials are typically very expensive. Particularly, weight for weight, CFRP(carbon-fiber-reinforced plastic) offers 6 times more rigidity than steel, 3 times more post-elastic stiffness, and 4 times more lightness. The only drawback would be that it is much harder to stretch or bend. This material, therefore, has been only used for a few racing vehicles, such as i20 WRC Rally Car of the Hyundai Motors World Rally Team, which has won the manufacturers’ championship back in 2019. CFRP indeed is a very luxurious material.

Recently, Hyundai/Kia has applied the CFRP to its commercialized models. The brand-new ‘N Performance Parts’ include various types of tuning parts – carbon front lip, carbon rear diffuser, carbon rear spoiler, carbon side mirror cover, etc. The Kia Stinger and the Genesis G70 also house Real Carbon Interior Trim that uses CFRP.

Alcantara: Water-and-Stain-Resistant

Alcantara is the brand name of a common synthetic textile material.

At only 1/400 the thickness of a strand of hair, it has a soft, suede-like microfiber pile and is noted for its durability. Alcantara is commonly seen in automotive applications, as a substitute for conventional materials in vehicle interior trim, such as suede. It is generally used for steering wheels, dashboards, gear knobs, door trims, or anywhere it is needed for a luxurious yet sporty atmosphere.

Hyundai/Kia also showcased interiors housing a lot of Alcantara. Inside the Alcantara Edition, the Kia Stinger has an Alcantara-wrapped steering wheel, gear selector knob, and center console armrest all of which are complemented by the suede-like headliner material. The Hyundai N Performance Parts also offers an interior package that includes the steering wheel, parking brake lever, center console, and shift lever boots that use Alcantara.

New Materials for Fog-Free Automobile Lamps

Headlamps are technically the eyes of a car. They are more important than anything else when you are driving at night. The light source is important, of course, but the fog issue has been quite an obstacle. Hyundai/Kia has recently applied a new headlamp that can fundamentally resolve the fog issue.

As a lamp has to endure up to 200℃ of inner temperature, the plastic starts to emit a certain kind of gas that makes stain on the lamp. To satisfy these challenging requirements, the Kia K9 added glass fiber to the existing plastic material to secure sufficient rigidity and also added high molecular weight additives, and as a result, it succeeded in developing the new material that satisfies various requirements without generating gases.

New Materials In the Future

As above, automakers have developed various kinds of new materials for their products’ efficiency, functionality, or safety. But future mobility will require revolutionary new materials more than ever, to meet the demand for better safety and efficiency.

Vehicles in the future will no longer be a simple means of transportation. The definition of mobility is changing rapidly, and it requires groundbreaking materials as a result. Materials indeed are a key factor in automotive industries.