First high-volume production start of electrically heated catalytic converter worldwide is part of Vitesco Technologies’ electrification strategy

Production start for multi-million contract relating to electrified vans planned for late 2022

Innovative electric catalytic converter aimed at ensuring vehicles comply with planned stringent Euro 7 standard

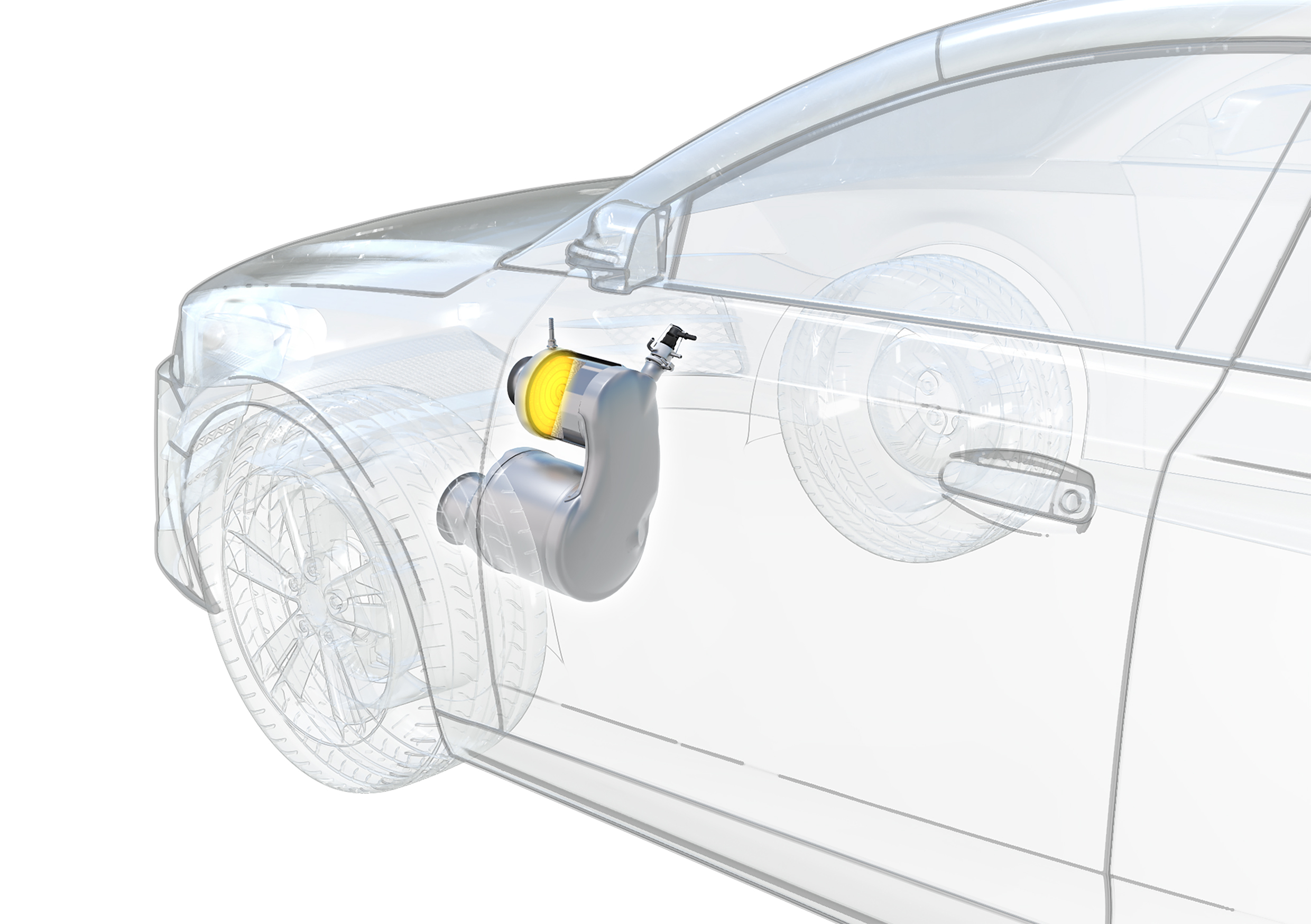

Regensburg, March 12, 2020. Vitesco Technologies, a leading supplier in the field of vehicle electrification, and Continental’s Powertrain division has won a major contract from an European vehicle manufacturer for the supply of innovative electric heating elements for diesel catalytic converters. This EMICAT brand e-catalyst technology will be used in two of the manufacturer’s 48-volt hybrid van models. Start of production for the multi-million contract is scheduled for 2023.

The capability to rapidly heat up the catalytic converter at all times increases the overall efficiency of exhaust-gas aftertreatment. This means that the vehicles will be prepared to meet the future extremely stringent Euro 7 standard. The EMICAT e-catalyst developed by Vitesco Technologies is a form of smart electrification for combustion engines. It ensures effective exhaust gas aftertreatment, even when the exhaust gas is actually too cold for this purpose. This is the case, for example, when a diesel engine is producing very little heat in slow urban traffic. The 48 V current for the e-catalyst is obtained via recuperation in the vehicle’s mild hybrid system.

The innovative e-catalyst is part of Vitesco Technologies’ electrification strategy

“The electrification of the drivetrain, which goes along with higher electrical power, clearly supports emission reducing innovations like EMICAT®. The e-catalyst allows a robust emission control with regards to all real driving situations for an extremely clean future mobility”, says Klaus Hau, head of the Sensing & Actuation business unit at Vitesco Technologies. “EMICAT® eliminates a decisive weak spot with regards to real driving emissions, namely excessively cold exhaust gases. The first serial production of e-catalysts worldwide confirms the importance of emissions safety in all driving situations”.

Klaus Hau: „EMICAT® eliminates a decisive weak spot with regards to real driving emissions, namely excessively cold exhaust gases.”

Emissions safety – even when cold engine starts becomes’ the norm

The high efficiency of modern diesel engines means that the engine barely gets warm in certain operating situations. In principle, this is desirable, as lost heat means lower efficiency. However, exhaust gas pollutants can only be converted into harmless substances in a catalytic converter if the exhaust gas and therefore the catalytic converters are sufficiently hot. This is often not the case, particularly in slow inner-city traffic where conditions previously only familiar during cold engine starts are frequent. “This is critical for compliance with stringent emission standards because the vast majority of pollutants in a test cycle are released during the cold start phase,” explains Rolf Brück, head of Catalytic Converters and Filters at Vitesco Technologies.

This EMICAT® technology will be used in two of the manufacturer’s 48-volt hybrid van models

In vans equipped with 48-V mild hybrid technology, the current harvested during recuperation is used to heat up the catalytic converter system in these situations. “Then, exhaust gas aftertreatment also works reliably” adds Brück.

Complete system successfully tested in research vehicle

In a dedicated mild hybrid demonstration vehicle with a diesel engine, Vitesco Technologies has demonstrated the effect that the EMICAT® can have with its 4kW heating output: In the Super Clean Electrified Diesel vehicle featuring a 48-V system, NOx emissions dropped by 40%, and CO2 emissions decreased by 3% in the WLTP test. In the extremely slow “Traffic for London” cycle, NOx emissions even fell by 62%. In the Super Clean Electrified Diesel, the efficiency of exhaust gas aftertreatment rises to 97%.