» Download all images (ZIP, 5 MB)

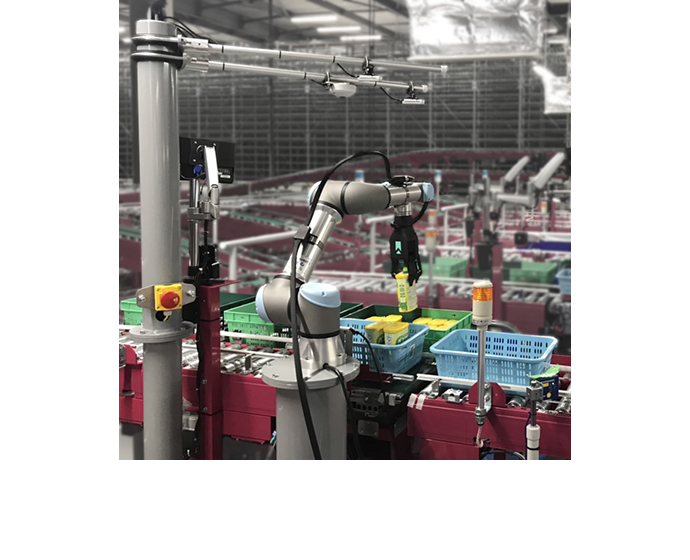

Due to the global pandemic, this year’s e-commerce sales are on the rise. Growth in online retail has placed increased pressure on warehouses to keep up with higher volumes of orders and with social-distancing protocols that have restricted the number of staff allowed on-site. Massachusetts-based RightHand Robotics addresses these challenges with its RightPick2 robot, powered by the Intel® RealSense™ D415 Depth Camera. The RightPick2 is an autonomous robotic piece-picking solution and labor multiplier that allows for rapid order fulfillment with little to no human contact.

More: Intel Real Sense (Press Kit)

The Intel RealSense D415 provides each RightHand robot with the ability to discern objects and their locations in a bin, while avoiding collisions when pulling them out. The camera also provides the data that helps RightHand Robotics improve its platform over time. Depth images from the Intel RealSense D415 gathered over millions of individual picks help RightHand learn the best way for the robot to approach different shapes and classes of items.

Aided by the RightPick2 robot, a single warehouse worker now has the ability to manage a fleet of robots, picking and placing thousands of SKUs instead of having to search warehouse aisles. This results in each robot significantly reducing lead times by fulfilling orders accurately at high speeds, and ultimately enables businesses to give customers what they need.

The RightHand Robotics solution is targeted to make warehouses safer for employees amid the pandemic and help facilities reopen while adhering to distancing guidelines. With more warehouses rapidly adopting the digital warehouse model, robotic process automation fueled by Intel RealSense technology provides a way to more efficiently fulfill the growing demand.

Customer Stories: Intel Customer Spotlight on Intel.com | Customer Stories on Intel Newsroom