The new innovation lab will be located in Singapore’s Jurong Innovation District, a one-stop advanced manufacturing hub developed by Hyundai Motor Group, housing a vibrant ecosystem of researchers, technology, and training providers and factories of the future. The lab will explore business ideas and technologies to revolutionize a value chain encompassing R&D, business such as test drive, and production for future mobility solutions for the fourth Industrial Revolution. It also will help define the future business direction for the company, being a testbed. Here’s the trailer video of HMGICS, showing the automaker’s vision.

HMGICS to Serve as an Innovation Center in Singapore for Future Mobility Studies

HMGICS is an innovative manufacturing platform that implements advanced mobility life with continuous orders, productions, test-drives, and services; and is planning to build overall customer experience facilities, R&D centers, and small-size EV manufacturing facilities that would take up a 90,000-square-meter, seven-story building.

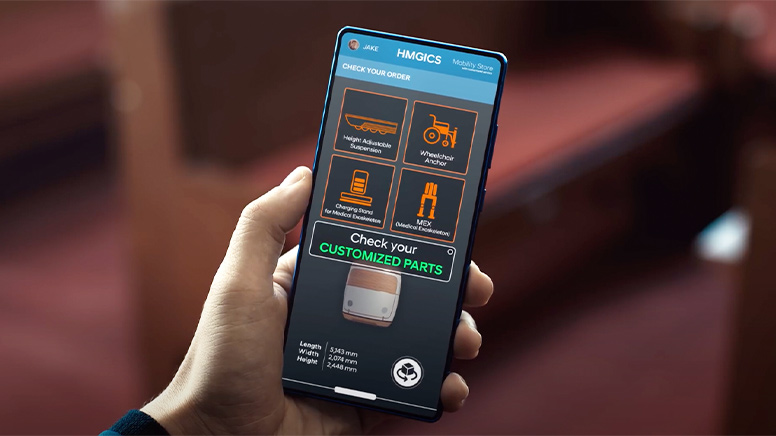

The HMGICS introductory video recently unveiled by Hyundai Motor Group shows an advanced mobility life that it will create, through one family with a daughter who is about to get married. The story begins with showing the groom conveniently orders a Purpose Built Vehicle and MEX, a medical wearable exoskeleton, using his smartphone, for his father-in-law-to-be.

Next, the video shows a small electric vehicle manufacturing facility with cutting-edge production technologies that produces customized PBVs. PBV is one of Hyundai Motor Group’s future mobility solutions unveiled at the Consumer Electronics Show 2020 in January this year. Hyundai Motor Group has proposed a new mobility environment for future cities through three solutions: Urban Air Mobility (UAM), Purpose-Based Mobility (PBV), and Mobility Transfer Base (Hub).

Smaller Production Systems with Smart Factory Technologies

Highly automated smart factory technologies are introduced in HMGICS’s small EV-manufacturing facilities. Based on an intelligent manufacturing platform that combines various cutting-edge technologies such as artificial intelligence (AI), the Internet of Things (IoT), and robotics, it is a small-scale multi-model production system that responds to the demands and the changes in the market with flexibility. When realized, Hyundai’s new manufacturing platform will help make automotive plants safer and greatly diminish the physical burden for workers, using manpower only where necessary, using the assembly line called ‘Cell’.

The video now shows the wedding day. The father of the bride rides the PBV that his son-in-law gave him, and moves comfortably to the ceremony. He is wearing MEX, a wearable robot the groom ordered as an additional option of a custom PBV, so they together walk down the aisle without relying on a wheelchair. Developed by Hyundai Motor Group, MEX is a medical robot that helps paraplegic patients walk with the lower body, which supports muscle movement like the exoskeleton of crustaceans. It also provides customized walking patterns by adjusting walking speed, stride, and angle of body tilt according to settings. Hyundai Motor Group’s human-centered technology can indeed help those who are not able to walk.

For your information, Hyundai Motor Group’s wearable robotics technology was first applied to industrial sites. Vest EXoSkeleton (VEX), which was put on trial at Hyundai Motor’s Alabama plant and Kia Motors’ Georgia plant in the U.S. in January 2019, is a case in point. The VEX functions without the need for a battery by imitating the human shoulder joint and using a multilink lift assistant module. It is so light that it weighs only 2.5 kilograms that it reduces musculoskeletal disorders and increases work efficiency where they look up and raise their arms for a long time. It is to increase freedom of movement and support muscles of the workers, and it can also adjust settings accordingly depending on the worker’s body shape, muscle strength, and working environment.

The customers being able to watch the production process of a vehicle suggest that HMGICS can be a new example of a customer experience. Customers who visit HMGICS will test drive the vehicle produced on the sky track on the roof of the building before the final delivery. The rooftop will have a 670-meter-long sky track with high-speed driving, as well as a take-off and landing ground for urban aviation mobility. In addition, solar panels that produce eco-friendly energy will be installed as a part of Hyundai Motor Group’s efforts towards carbon neutrality, resource protection, and its circulation. Hyundai Motor Group’s vision of being responsible for the local community and humanity surely is to contribute to future generations. In addition, the video showing the unique exterior of a building indicates that HMGICS will be a new landmark in Singapore.

Realizing Advanced Mobility Value Chain

The PBV in the video features various specifications in consideration of passengers using wheelchairs. The entrance with the ramp is wide enough to make it easy for wheelchairs to get in and out of the PBV. In addition, the floor houses a device that holds the wheelchair so that it does not move while driving. In addition, the PBVs feature self-driving technologies with voice recognition control, so that the passengers can just say their destination out loud. It is a realistic implementation of a smart mobility environment in which humans can enjoy a better life through customized mobility vehicles and services.

As such, Hyundai Motor Group plans to provide customized products optimized for customer needs. In addition, the company plans to discover new future mobility projects that will contribute to a sustainable society; so the automaker will offer such a lifestyle with its various mobility services. Through the Battery as a Service (BaaS), a battery life cycle-related service, the company plans to rent expensive electric vehicle batteries at low prices to reduce the burden and improve utility.

Singapore, Testbeds for New Technologies in Southeast Asia

So why is HMGICS being established in Singapore? Singapore is a leading Southeast Asian country when it comes to innovative technologies, housing global companies, world-class universities, and specialized research institutes, being optimized for developing new future mobilities. It is also considered the best new technology testbed in Southeast Asia for its hospitality towards the IT industry. Based on the superb human resources in Singapore, HMGICS will be used as a stepping stone for developing new future mobility while collaborating with multiple innovation ecosystems in Singapore. It will also push for other mobility-related businesses in combination with HYUNDAI CRADLE, Hyundai Motor Group’s global innovation hub, and AIR CENTER, the AI-exclusive research facility.

From placing orders to providing services, HMGICs will become Hyundai’s global open innovation hub. The lab, through open innovation on multiple fronts, will explore and prove new future mobility business concepts for eventual expansion into global markets, calling for the fourth Industrial Revolution. HMGICs will validate concepts including multi-modal mobility service. Combining AI, the Internet of Things (IoT), and other advanced technologies, the lab will create a human-centered smart manufacturing platform that will be validated through a small pilot EV production facility. In conjunction with the platform, an innovative product development process and on-demand production system will be tested and proven. Also, HMG will also provide medical wearable robotics such as MEX, or special mobility such as PBV, for those who are not able to use regular means of transportation. Everyone is looking forward to the innovative mobility ecosystem that HMGICS will bring to change the paradigm of future mobility.