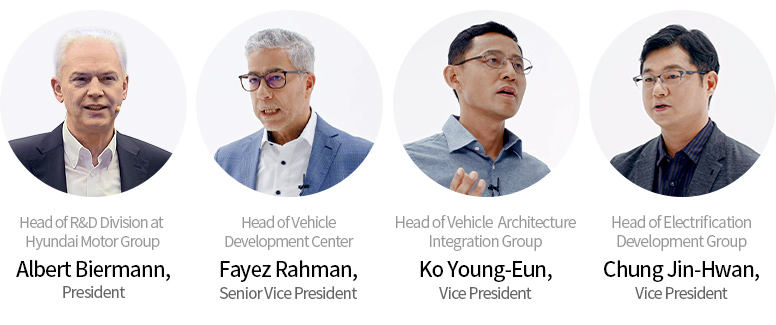

On Dec. 2, Hyundai Motor Group unveiled on Youtube the Electric-Global Modular Platform (E-GMP), the group’s first dedicated platform for BEV. Its optimized design for BEVs makes it more efficient and eco-friendlier than ever—it certainly appears that the group’s long-accumulated know-how in electrification is poised now to usher in a revolution in how we experience electric vehicles. To address our curiosities about this important innovation, we interviewed four executives from Hyundai Motor Group: President Albert Biermann, Head of R&D at Hyundai Motor Group; Senior Vice President Fayez Rahman, Head of Architecture Development Center; Vice President Ko Young-Eun, Head of the Automobile Architecture Integration Group; and Vice President Chung Jin-Hwan, Head of the Electrification Development Group.

Q. Compared to EVs built on Internal Combustion Engine Vehicle (ICEV) platforms, what are the advantages of those built on the E-GMP?

Ko Young-Eun: The difference begins with the fact the E-GMP was tailor-made for BEVs from the start. It can accommodate more batteries, which increases the driving range, not to mention availing greater power. The E-GMP’s design also allows for much bigger cabin space, with the wheelbase (the distance between the front and the rear axles) made as long as possible and the bulky engine replaced by the remarkably compact Power Electric System (PE System); the EV equivalent of an ICEV’s powertrain). This structural change from the ICEV’s engine room also ensured optimization in curb weight. And finally, the E-GMP opens for us the doors to developing high-performance EVs with powerful motors on both front and rear wheels.

Chung Jin-Hwan: We know that charging EVs is stressful for our consumers. So we have applied onto the E-GMP the 800V high-speed charging system, which significantly reduces the charging time relative to BEVs based on ICEV platforms. High-speed charging charges the battery up to 80% of capacity within 18 minutes. The Vehicle-to-Load (V2L) feature allows appliances to run on the car’s battery. Finally, we have applied durable and efficient Silicon Carbide (SiC) power semiconductors to ensure that the high-voltage charging system runs with the equally high-quality drivetrain.

Fayez Rahman: ICE platforms necessarily come with very large engine rooms, which BEVs have no need for. So the wheels can be pushed farther out to the edges of the vehicle, allowing for fresh, unprecedented, and futuristic design concepts. For example, the vehicle floor can become completely flat because of the lack of the center tunnel in the bottom of the car. And the climate control unit in the dashboard might move into the space that once was occupied by the engine bay, leading to what we call the “Slim Cockpit” design. The cabin space has become large and flexible, and we can now even attempt unprecedented design proportions by, say, equipping larger-diameter tires.

Q. What would you say distinguishes the E-GMP from its competitor platforms?

Albert Biermann: If you measure the amount of time necessary to charge a BEV to run 100 kilometers, I fully expect our vehicles with the E-GMP to come out on top. The 800V high-speed charging system with silicon carbide power semiconductors will do that. And what’s more, the BEVs based on the E-GMP can be made highly powerful—up to 600 horsepower—meaning they stand out in being able to offer acceleration performance features like racetrack features.

If you look at the vehicles based on the E-GMP, you will see that there are significant changes in design beyond just interior space and functionality. The E-GMP is all about freedom in vehicle design. At a time when most EVs being released in the market are looking rather similar, the E-GMP will offer some standout, unique exteriors that will appeal to the customers. We feel it will be embraced by the market.

So yes, the exterior stylings are a big plus for the E-GMP, and particularly, the large and prominent wheels are the focal point of our designs. While the other competitor models churn out the same stylings after another, we are planning to release our uniquely designed EV lineups across Hyundai, Kia, and Genesis brands. Of course, it’s not just the facade that will attract; their spacious interior will offer the consumers new UX and lifestyle utility.

Fayez Rahman: We put consumer needs first in developing the E-GMP; put simply, it’s a human-centered platform. Its basic configuration is made to prioritize convenience, comfort, safety, and generous driving range. And the scalable PE concept, as well as the other technologies in development, will allow us to flexibly and efficiently meet the evolving demands of the market.

Q. Currently, most charging infrastructures in the world feature the 400V fast-charging systems. Given this, why did you feel compelled to develop the 800V high-speed charging system?

Chung Jin-Hwan: Car chargers’ cable and connector sizes are determined by the electric current; the larger the current size, the heavier the cable and the parts become, which makes charging inconvenient. One way to alleviate this inconvenience is to increase the voltage. The 800V high-speed charging system comes with twice the output of the mainstream 400V system, so in theory, it cuts the charging duration in half, which is obviously desirable. But given that the 400V systems are still the mainstream, the E-GMP was equipped with the first multi-charging system in the world that accommodates both 800V and 400V charging.

To use 800V high-speed charging with an ordinary 400V fast-charger, one requires a booster converter. But the E-GMP uses the motor system in the car to do the boosting without the need for that additional adapter. This multi-charging system is patented by Hyundai Motor Group as the first of its kind in the world.

Albert Biermann: The market for high-voltage charging systems will only grow in the future. And Hyundai Motor Group is the first manufacturer to mass-produce 800V systems; sure, some sports cars support 800V systems now, but they are very expensive. Our systems are competitively priced to facilitate demand and let the market grow. It’s only a matter of time until 800V systems supplant 400V ones, and then we will be in our labs to develop even higher-voltage ones.

Q. Is E-GMP’s charging still efficient with a standard 400V charger?

Chung Jin-Hwan: As stated, the efficiency boost comes from using SiC power semiconductors, which doesn’t go away even if you do 400V charging. So the efficiency is maximized, regardless of which charging method you choose. To be more specific, most quick-charging infrastructure to date for 400V charging comes with chargers with wattages between 50kW and 150kW. The E-GMP is built to easily accommodate that maximum of 150kW.

Q. Does the E-GMP come with wireless charging technology?

Chung Jin-Hwan: It’s in development, and we have been resolving many issues that inherently arise with wireless charging. The car itself needs some technological updates to accommodate it, and we need to build a transmission unit on the bottom of the platform to generate and transmit electricity. That is to say, the development is still ongoing on both ends, and only after the development is done will we be able to apply the technology to our mass-produced vehicles. The timetable for that application is flexible, dependent on market reactions and changes in the business environment.

Q. The E-GMP uses pouch cells. What is their relative advantage to cylindrical cells?

Chung Jin-Hwan: Pouch cells have the ideal shape for vehicles, so they can be efficiently laid out depending on the size of the car. And their capacities are significantly higher than those of cylindrical cells, so you don’t need as many battery cells to satisfy the demand for energy capacity, which translates to cost and procedural savings during production. This is not to say that we have dropped cylindrical cells altogether—technological development has seen their capacities steadily increase as well, so we are continuing to monitor all options for the future.

Q. How did you secure the safety of the battery pack? Does the E-GMP have a special plan for contingencies?

Ko Young-Eun: This was one of our major concerns during the E-GMP’s development. In terms of BEVs, ensuring safety does not simply mean ensuring the occupants’ safety. The battery needs to be protected as well. To that end, the E-GMP was designed to structurally distribute and absorb the collision energy in the event of front and rear crashes, and the battery’s vicinities received protective reinforcements with ultra-high strength steel. Furthermore, the side sill received extruded aluminum for added structural protection. During the development, all vehicles received routine crash tests and were vetted for safety performance. The PE System received similar structural reinforcements for safety’s sake. If a crash leads to a leakage of coolant liquid, and that liquid seeps into the battery cells inside, short-circuiting will occur and potentially cause a fire. To prevent this, we physically separated the system from the battery so as to drain the coolant outside of the battery premises.

Q. What are the release plans for models based on the E-GMP?

Albert Biermann: The first one in line will be the Hyundai IONIQ 5. And next year, we’ll get Kia’s first E-GMP exclusive BEV line on the market—and just as the IONIQ line offers a variety of segments, the Kia’s new BEV line will offer a wide range of choices of segment: sedans, CUVs, SUVs, 7-seater SUVs, and so on. Meanwhile, our existing EVs on ICEV platforms will see some expansions into smaller segments as well.

Q. Are there any plans to apply the E-GMP on N Brand’s high-performance cars? If that does happen, do you think that it is possible to simulate the sporty ride feel of the N on an EV?

Albert Biermann: Of course, we are considering it. In fact, we’re debating that issue internally right now and already possess the technological wherewithal to do it. We are looking to release many high-performance models next year, and our consideration is not confined to just the N Brand but includes some performance models from Kia and Genesis.

As for the concerns about the ride feel, there is no need to worry. I have test-ridden many times the IONIQ 5, the first model with the E-GMP, and despite its large battery and high-performance electric systems, the ride always felt absolutely pleasurable and oozed with dynamism. The handling and responsiveness were particularly top-notch. So I have full faith that a hypothetical N brand model on the E-GMP will be even more pleasing to any driver’s sensibilities.

Q. Any comment on the E-GMP’s versatility as a platform?

Fayez Rahman: The E-GMP can be used for C-segments, E-segments, CUVs, sedans, SUVs, 7-seater SUVs… basically, regardless of body type or size. This structural flexibility, coupled with the modular system and the scalability of our technology and solutions, makes the E-GMP incredibly versatile in accommodating vehicles of various specifications and characteristics.

Q. Is there a plan to even accommodate commercial vehicles or hydrogen fuel cell vehicles?

Albert Biermann: we are collaborating with an autonomous mobility company Motional to build a “robotaxi” based on the E-GMP. Robotaxi is envisioned as a massive high-tech transportation service. We plan to aid its development and commercialization with the E-GMP, whose high efficiency, long driving range, and high-speed charging are a perfect fit with what the serve is looking for. And as for the hydrogen fuel cell question, no, the E-GMP is dedicated only to BEVs. While adapting it to hydrogen fuel cells is technologically feasible, we are not pursuing that avenue right now. Hyundai Motor Group already possesses excellent FCEV capabilities apart from our BEV division— so we are not looking to integrate them at this time.