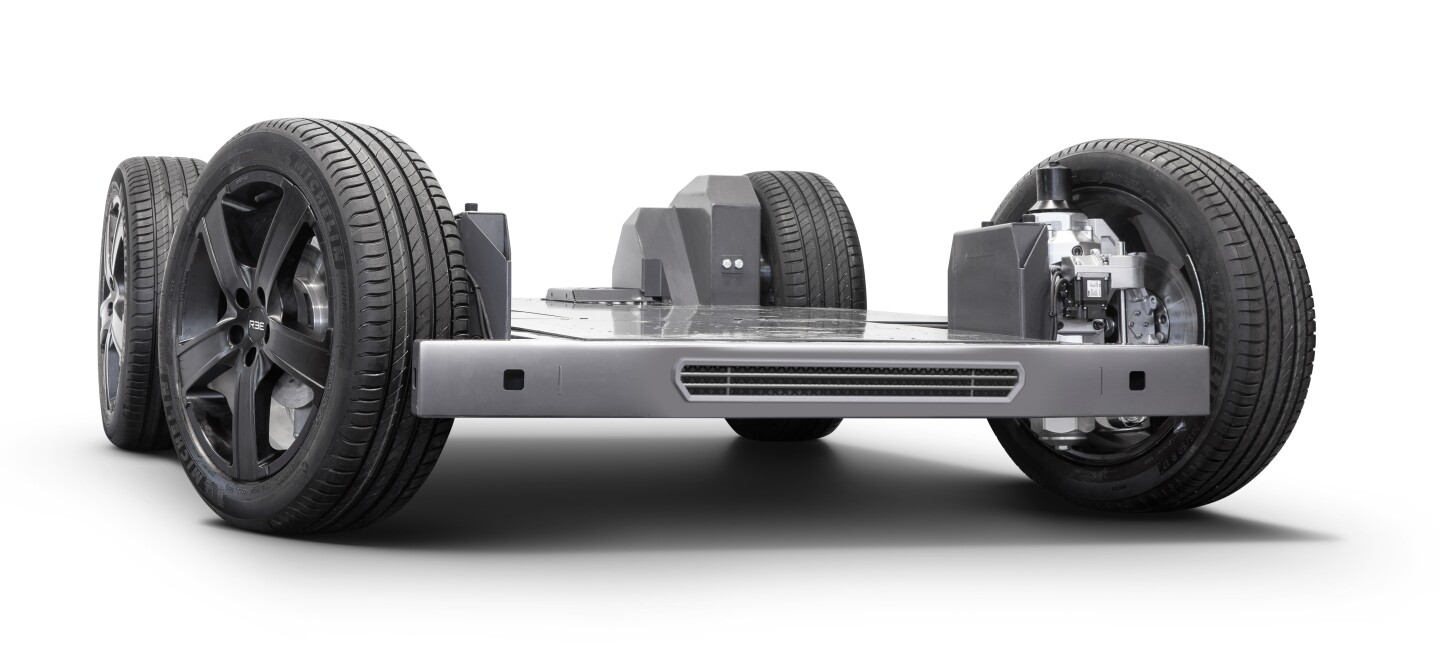

We’ve written about Israeli company REE Automotive and its remarkable super-flat modular EV chassis several times before. The company has a drastically disruptive offer for automakers; we’ll build you a skateboard electric vehicle chassis full of batteries, as well as your entire electric drivetrain, with more or less whatever characteristics you want in the motors, brakes, suspension, transmission and steering, using tier one suppliers. All you have to do is build the rest of the vehicle on top of it, however you like.

Not only that, the entire drivetrain is fully electronically controlled, and built into “REEcorner” modules that bolt on and off behind the wheels. Maintenance is a breeze, fleet owners can simply swap out faulty units for fresh ones. And the vehicles in question, which could range from tiny delivery pods through passenger cars, vans, 4WDs and all the way up to large electric trucks, can be driven equally well by humans, remote control units or autonomous systems. The platform doesn’t care; it’s everything-by-wire, the REEcorner units will accept electronic inputs from anywhere you like.

It’s a heck of a pitch; once a chassis is crash tested and homologated it can provide the underpinnings of a range of different vehicles, with a vast reduction in development cost. And it’s landing; Toyota’s trucking subsidiary Hino is using the REE chassis as the basis for its new FlatFormer range, for one, and Indian automotive manufacturing giant Mahindra has signed on to a strategic collaboration based around electric commercial vehicles.

REE Automotive

And now, after announcing it’s going public on the NASDAQ through a SPAC merger, REE has announced it’s investing US$92 million over three years in a “new state-of-the-art Engineering Center of Excellence” in the UK, where up to 200 employees will work to “accelerate our validation, verification and testing as well as product homologation,” says REE co-founder and CEO Daniel Barel in a press release.

The location is key; REE’s new facility is in the MIRA Technology Park, near Hinckley in the British midlands, a haven for the UK automotive industry. Other MIRA tenants include Aston Martin, Bentley, Bosch, Continental, Goodyear, Jaguar Land Rover, Michelin, Pirelli, Toyota, Triumph, Royal Enfield, Bridgestone and many other supply companies. REE will be exceptionally well placed to source talent and develop relationships both with component suppliers and potential customers.

The company is also planning to establish 15 integration centers where it will assemble the REEcorner modules designed in partnership with component suppliers. The first, it says, will be opened in the USA this year, with REEcorner unit deliveries starting in 2022 and mass production starting in 2023 to start filling some 250,000 platform orders for which the company says it has “signed indications of interest,” if not solid orders as yet.

REE Automotive

The REE model represents an absolute upending of the automotive business in which automakers can more or less outsource the expensive platform and powertrain development process and concentrate on customer experience, interior and exterior development.

The proposition borders on offensive; this cuts right to the heart of what it means to be an automaker, but then, it raises the question: how much does proprietary motor and chassis technology even matter in the electric future? Surely not as much as it has in the ICE age. And when customers have the ability to do drive-in, drive-out corner unit replacements to fix nearly any motor, chassis or drivetrain issue – or heck, even swap out the commuter units for long-travel suspension and four-wheel-drive modules for a week on the trails, will that be a more compelling offer?

Interesting times ahead, and a fascinating company to follow.

Source: REE