Israeli EV startup REE Automotive, just unveiled its new approach to drive components and platforms. Named REEcorners, these proprietary systems fuse all of the vital parts of an EV together between the chassis and wheel. Combined with its modular EV platforms, REE Automotive sees its technology as a cornerstone for the future of electrified mobility.

REE Automotive is headquartered in Tel Aviv, with subsidiaries in the US, UK, and Germany. It specializes in developing and manufacturing REEcorners and modular EV platforms for B2B transactions. According to its website, REE has a unique CapEx-light manufacturing model that leverages its Tier 1 partners’ existing production lines.

Speaking of partners, REE recently announced a SPAC merger with 10X Capital Venture Acquisition Corp. ($VCVC). When the merger is complete, the EV platform manufacturer plans to list on the NASDAQ as $REE. The startup hopes the $500 million in gross proceeds will accelerate the mass production of its REEcorners and platforms, currently set for 2023.

In today’s press release, REE Automotive unveiled five new and improved REEcorner architecture designs. Furthermore, it shared technologies within its modular EV platforms, designed to support the broadest range of commercial electric vehicles.

REE Automotive’s REEcorner

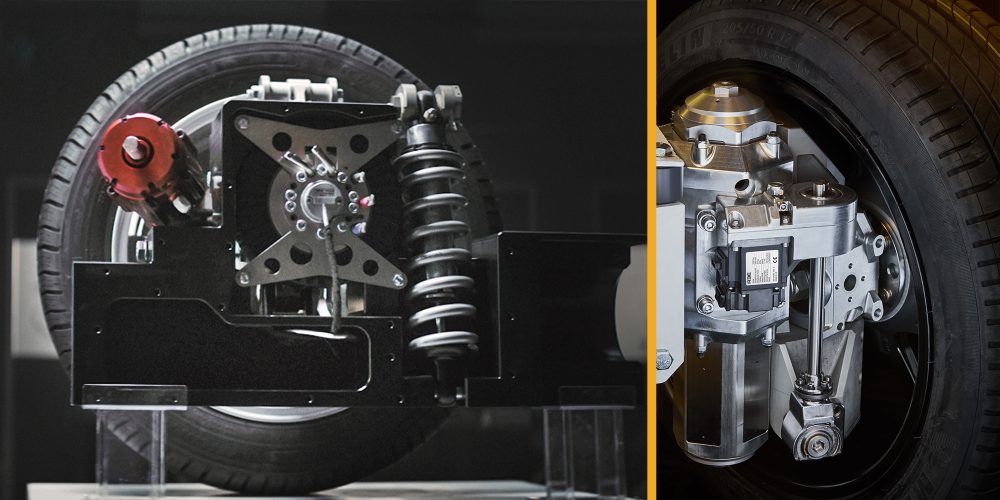

There is no shortage of startups pushing the boundaries of electric vehicle innovation. However, the REEcorner is unlike anything the EV world has seen so far. This technology integrates all the traditional drive components (steering, braking, suspension, powertrain, and control) into the arch of the wheel.

REEcorners remove bulkier components like steering columns, allowing for a super flat platform. This allows for complete modularity in terms of width, length, and even height. REE cofounder and CTO Ahishay Sardes explains:

Unlike in-wheel motor systems, the motors in REEcorners are fully sprung masses, positioned on the chassis side of the suspension. By minimizing unsprung mass, REEcorners are designed for optimal ride and handling vehicle dynamics. REE’s plan to utilize true x-by-wire technology to control each of the corners of the vehicles with full drive-by-wire, brake-by-wire and steer-by-wire technology is expected to deliver vehicle stability, responsiveness and safety with fully independent wheel control.

REE’s design further includes the REEcenter ECU (Electrical Control Unit) system to coordinate all four independent REEcorner ECUs, a thermal management system, power converter and power module. We believe that future customers who choose to build their electric vehicle fleets leveraging REE’s technology and EV platforms will benefit from significant operational and functional benefits over conventional EV fleets.

REE’s fully flat platforms feature a lower center of gravity than conventional EVs with motor(s) between their wheels. As a result, EVs on this platform are intended to carry more passengers, cargo, and batteries. REE’s smaller footprint and lower center of gravity will also allow for taller cabins and lower step-in height.

REE’s EV Platform

Just when we thought skateboard platforms and wheel hub motors were the future, REE introduces its own cornerstone technology. Thanks to space-saving REEcorners, platforms remain entirely flat with no components limiting it from expanding in any direction. This makes the platform fully customizable for any customer, whether the priority is cargo, passengers, or battery capacity.

Additionally, REE’s platforms are completely agnostic, leaving the door wide open for any power source or method of control. Fuel cell manufacturers rejoice! REEcorners give each company the freedom to create custom platforms large and small.

In addition to customized dimensions, REE is promising a comprehensive range of other technical configurations to meet specific customer needs. Modular platform options also include front, rear, or all-wheel-drive and peak motor power ranges of 35-200 kW. Furthermore, customers can choose front or all-wheel steering, advanced suspension capabilities, and payload capacities of up to 5,000 kg (~11,000 lbs). You can see the full unveiling from REE here:

REEcorners and platforms offer modularity

Thanks to REE’s extensive modular capabilities, B2B customers can utilize REEcorners and platforms to customize vehicles for their exact needs. According to REE, Mobility-as-a-Service (MaaS) providers can build FWD electric shuttles. As a result, this will offer maximum payload capacity for transporting passengers, with minimal battery consumption.

Another example is logistics companies, who can instead choose low-speed, AWD, all-wheel steer REEcorner configurations for last-mile deliveries. Furthermore, REE’s platform will also offer low step-in-height and minimum-turning radius in congested urban areas. Lastly, REE’s EV platforms can also feature 360° accessibility for all sides, and unrestricted visibility for easy loading and unloading.

Electrek‘s take

We have a feeling we’re going to be covering REE Automotive much more as time goes on. Overall, this is due to the innovation we’ve seen from REE in a short period of time. The innovators at the company aren’t just thinking outside the box. They’ve taken that box and put all of its contents in each corner, leaving the rest endlessly customizable.

REE truly seems to be onto something with the combination of its REEcorners and platform. Through integrating critical components into each wheel independently with X by wire capability, there are no mechanical systems or linkages to worry about. For example, if one REEcorner is having an issue, it can be swapped out without affecting the entire EV.

As we noted earlier, these REEcorners leave additional coveted space for battery cells. Want more? Simply make the platform bigger; no big deal. REE’s platform, much like its technology as a whole, has a lot of potential. All in all, this is an EV company to keep an eye on.

FTC: We use income earning auto affiliate links. More.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.