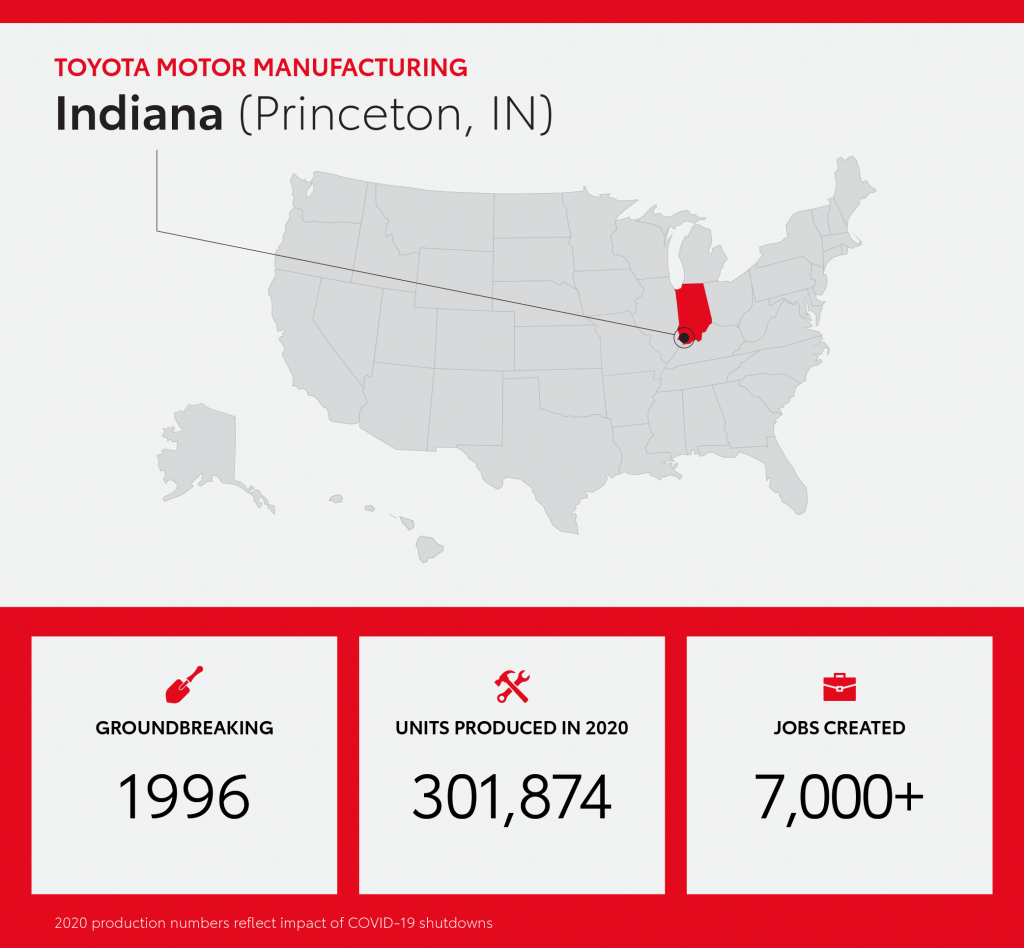

Toyota Motor Manufacturing, Indiana (TMMI) uses high-tech manufacturing systems to assemble some of the most technologically advanced vehicles on the road today. TMMI has assembled more than 6 million vehicles — and counting.

Since the plant’s groundbreaking in 1996, Toyota has invested $6.6 billion to make high-quality vehicles through smarter, flexible manufacturing and innovation. For instance, at TMMI employees work in tandem with robots to help increase efficiency. It’s not uncommon to see an employee donning an exoskeleton — like a harness — to get a boost and some support when working on a task that’s elevated. Employees also program the robots to perform various operations, including welding car body panels and painting bumper covers.

Cutting-edge innovations are embedded in Toyota’s DNA. In fact, the TMMI Experience Center contains a rare glimpse into Toyota’s trailblazing origins. TMMI is the only facility in North America, and just the second outside of Japan, to possess an Automatic Loom, Type G. The loom, the first of its kind in Japan, was invented in 1896 by Sakichi Toyoda. Since then, the automaker has continued to build on its pioneering heritage by bringing its state-of-the-art approaches to Indiana and all of its operations in the U.S.

Today, the plant employs more than 7,000 people who assemble some of Toyota’s most-loved vehicles, including the Highlander, Highlander Hybrid, Sequoia and Sienna. As part of Toyota’s continued investment in its U.S. plants, the automaker recently allocated $803 million and 1,400 new jobs toward its preparation to introduce two all-new, three-row SUVs designed with the active Gen Y American family in mind.

On top of its commitment to assembling better vehicles, Toyota is focused on helping the planet. The Indiana plant’s biodiversity efforts minimize the disruption of natural habitats and proactively support local species. At the TMMI Experience Center, guests can view plants native to Indiana in its pollinator garden and might even catch a glimpse of the facility’s flying “guests” from the comfort of an air-conditioned viewing area.

In addition, TMMI is committed to driving positive change in Princeton, Indiana and the surrounding communities. In 2019, the plant turned a planned shutdown into Impact Week, an initiative that led more than 400 employees to lend a hand and support local residents and 16 local nonprofit organizations in surrounding neighborhoods. In one week alone, TMMI donated nearly 3,000 work hours to benefit its community partners. TMMI has also granted more than $30 million to local nonprofits since 1996.

For 23 years, TMMI has been assembling cars and communities in the Princeton area.

Learn more about TMMI here.

Originally published September 2, 2021

Add to Cart

Add to Cart Print

Print Convert to PDF

Convert to PDF