The only place in North America that builds engines, transmissions and hybrid transaxles under one roof is Toyota West Virginia. The plant assembles products for the Avalon, Camry, Corolla, Highlander, Highlander Hybrid, Lexus ES, Lexus RX350, RAV4, Sienna and Sienna Hybrid. Today, the plant’s 2,000-employee workforce cranks out more than 1 million engines and transmissions per year. A new transmission rolls off the assembly line about every 25 seconds, with four-cylinder engines completed just under 30 seconds.

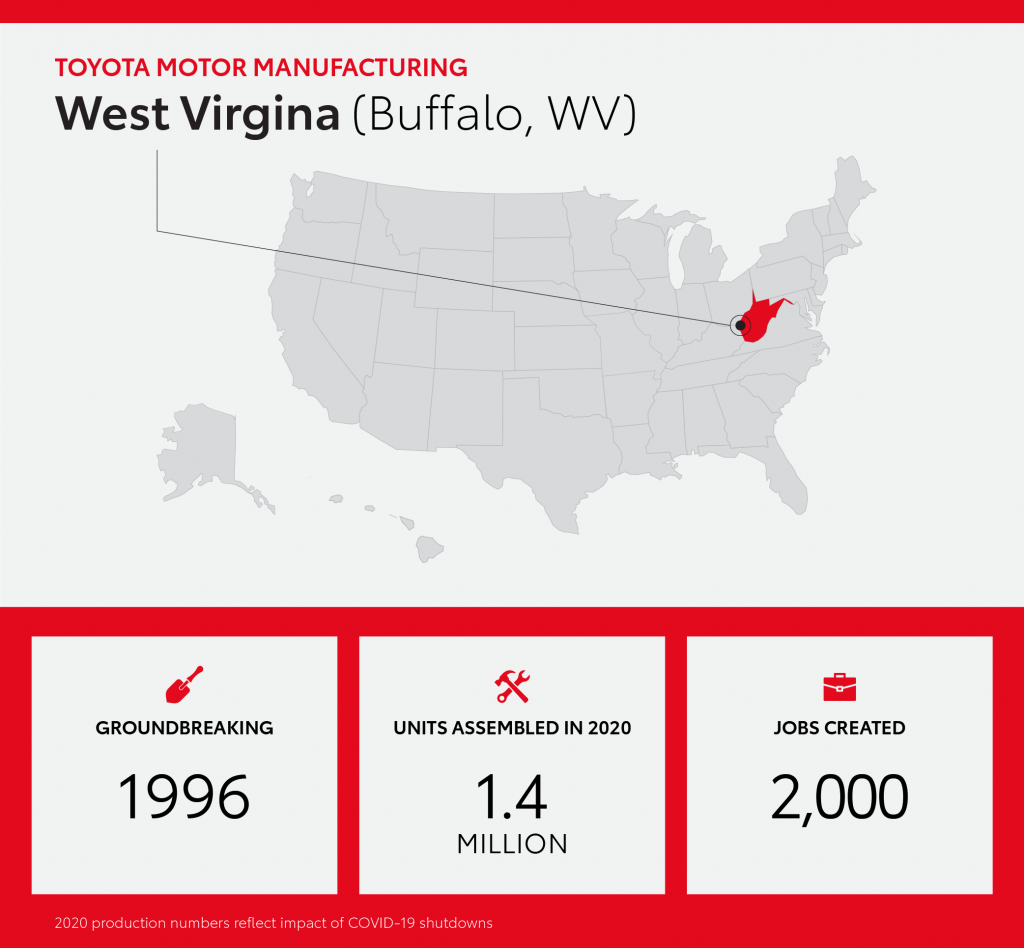

In May 1996, Toyota Motor announced plans to build a 230-acre property in Buffalo, West Virginia. The area was chosen to be the home of Toyota Motor North America’s first and only engine and transmission assembly plant. Upon groundbreaking in September 1996, Toyota originally built a team of 300 employees to produce 300,000 four-cylinder engines at the facility. But before construction finished in 1998, the plant added a V6 engine production line, marking its first expansion before the facility’s official opening.

Since 1998, 19.5 million engines and transmissions have been produced at TMMWV — up to 5,000 engines and transmissions can be constructed every day.

Toyota West Virginia’s employees are notably skilled, passionate and talented — a contributing factor to why the facility has been expanded nine times. Toyota has invested $1.8 billion in the plant making it one of the largest companies in the state. In mid-2020, breaking yet another record, TMMWV became the first Toyota facility in North America to assemble hybrid transaxles, built for the Highlander and Sienna.

Deepening its commitment to the environment, Toyota installed the largest solar panel array in West Virginia. The initiative uses solar energy to help power its manufacturing operations throughout the plant. The array spans 6 acres and generates 2.6 megawatts of solar-generated energy. To enhance biodiversity, TMMWV has a bio-diverse walking trail, known as the “Green Mile.” The path is certified by the West Virginia Division of Natural Resources and is recognized by the Wildlife Habitat Council.

Developing the next generation is also important to TMMWV. To introduce students to STEM education and the workforce environment, team members demonstrate how they program collaborative robots at community events, facility tours, career events and camps. These efforts allow them to show K-12 students that STEM activities are not only educational but fun too. And hopefully inspire students to one day join the only plant that manufactures three integral components for Toyota and Lexus vehicles.

Learn more about TMMWV here.

Originally published September 7, 2021

Add to Cart

Add to Cart Print

Print Convert to PDF

Convert to PDF