BERLIN — Volkswagen Group is using Tesla’s new European plant as a model for the construction of a new factory in Germany.

VW’s supervisory board approved on Dec. 9 a plan to add a new electric car factory near its home factory in Wolfsburg. The site will build VW brand’s flagship Trinity car that will have advanced self-driving technology.

A decision on the exact location of the greenfield site could be made as early as the next few weeks, and the building itself will be built within three years, Christian Vollmer, the automaker’s production boss, said.

This means construction should take only a little longer than Tesla’s Gruenheide factory near Berlin, which aims to be completed within two years.

“We will need no longer than three years to build the Trinity plant,” Vollmer said in an interview with German business publication Wirtschaftswoche, as reported in Automotive News Europe sister publication Automobilwoche.

Vollmer said as soon as the location has been decided, construction can begin quickly. “Then, according to current planning, the plant should be ready in 2025, so that series production and deliveries can begin as planned in 2026,” he said.

The aim is to build a single-story plant, because that is the most efficient solution, Vollmer said, however if the area is too small, a two-story construction can be used in some areas.

According to information from Automobilwoche, the factory area will cover 2 square kilometers, which is almost one third of the area of the current main plant, with approximately the same volume to be added for logistics and suppliers.

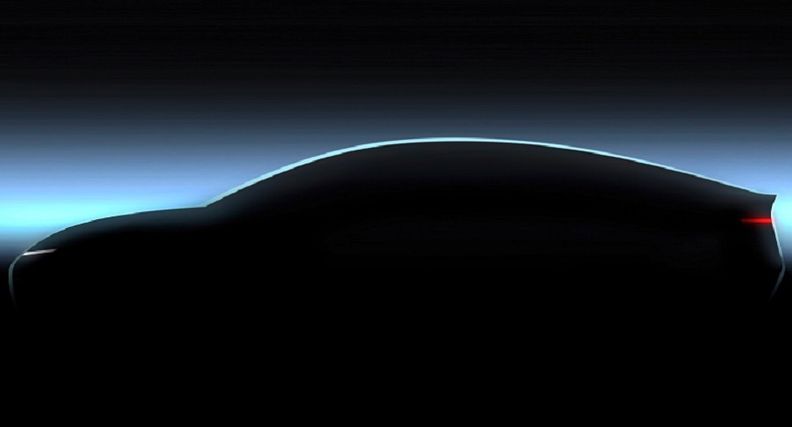

VW’s new factory will build a flagship electric car, previewed here in a sketch released by the automaker.

Similar to the Tesla plant, the Trinity plant could also produce car bodies from just a few huge parts.

“The use of large cast aluminum parts for the front and rear of the car, for example, could speed up production,” Vollmer said. “That is why we are looking at using it in Trinity production.”

However, he said, this has not yet been decided. That is because in addition to pure production speed, one also must look at CO2 emissions, material costs and safety, Vollmer added.

“So, it may be that large components made of steel end up being more advantageous for us,” he said. “Large aluminum casting presses are a possibility, but not a must for us.”

The plant could then even use drones to transport parts, Vollmer said.

In addition, the company is considering having vehicles drive autonomously through the plant while it is still in production.

“I think it’s very realistic that the Trinity vehicles are already on the road autonomously in the factory, for example, to drive to parking locations or to do test drives for quality assurance,” Vollmer said.

Vollmer said he did not yet want to comment on the possible location, but according to reports, both the city of Wolfsburg and neighboring municipalities are trying to win the bid.

In order to be able to start construction quickly, VW is specifically looking for sites that are already fully or partially developed, which is the only way to keep to the ambitious schedule.

According to reports, the Wolfsburg district of Warmenau, which is separated by the river Aller and borders directly on the north of the VW plant, is the one that is most hopeful for the factory. The development and IT service provider Capgemini recently opened a new campus there.

The district town of Gifhorn, 20 km (12.5 miles) away, is also being discussed as a location.

Just a week ago, there was a meeting with Wolfsburg’s mayor Dennis Weilmann, of which VW Group CEO Herbert Diess subsequently shared a photo on LinkedIn. Diess was joined by Daniela Cavallo, head of the Works Council, and Gunnar Kilian, member of the Board of Management responsible for Human Resources.

“I am excited about the momentum with which issues are now being driven forward,” Diess wrote on LinkedIn. “Our new Trinity plant will set productivity standards and we will also increase the attractiveness of Wolfsburg’s city center.”