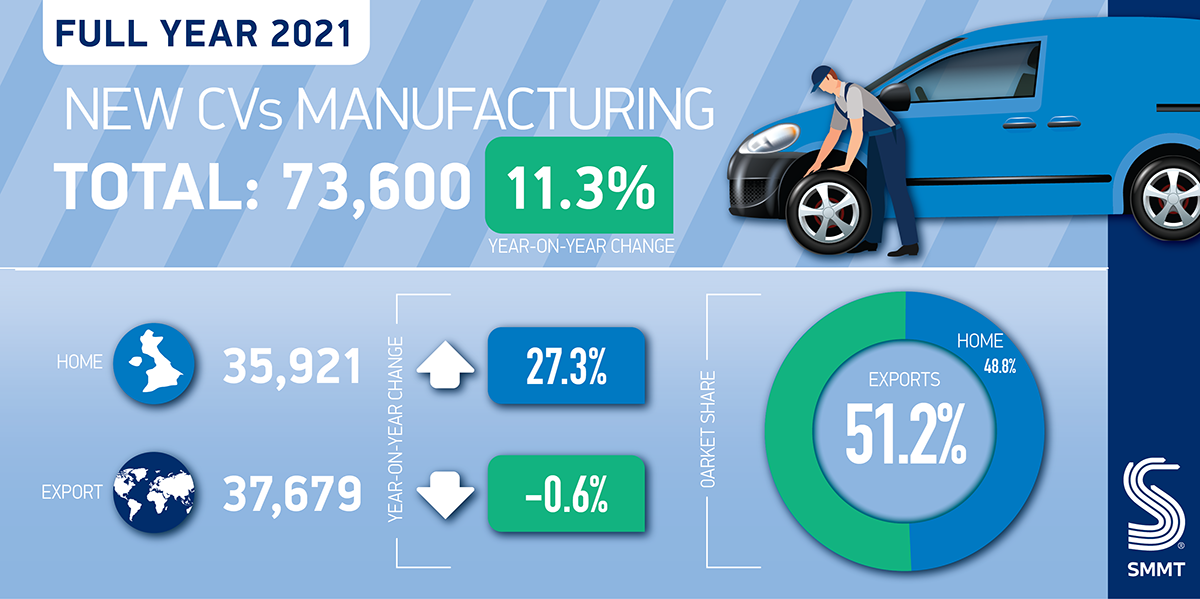

- British commercial vehicle production rises 11.3% to 73,600 units, but remains -14.4% down on pre-pandemic five-year average.

- Increase driven by production for UK, up 27.3%, while output for overseas markets broadly stable, down -0.6%.

- More than half of all British-built CVs exported, with the majority destined for EU roads.

UK commercial vehicle (CV) production grew 11.3% in 2021, following the worst year on record (dating back to 1933), with 73,600 of the latest vans, trucks, taxis, buses and coaches leaving factory lines, according to the latest figures released today by the Society of Motor Manufacturers and Traders (SMMT).1

Despite the global semiconductor shortage – a by-product of the Covid-19 pandemic – CV manufacturers demonstrated their resilience, securing component supply allowing production lines to remain fully operational. Growth was largely driven by an increase in sales of rigid 2 axle trucks and vans as demand for home deliveries soared during lockdowns. December’s output grew 3.2% to finish off a robust year, given the challenging business environment.

While this is positive news, it must be viewed in the context of a Covid-ravaged 2020, which saw social distancing measures and lockdowns throughout the year badly affect manufacturing capabilities. The 2021 performance, although an improvement on 2020, was still -14.4%, or some 12,356 units, down on the five-year pre pandemic average.2

Over the course of the year, production for the UK increased by more than a quarter (27.3%), while manufacturing for overseas markets was broadly stable, down just -0.6%. Despite this, more than half (51.2%) of all output was exported, with the bulk heading to EU markets (93.2% export share).

Mike Hawes, SMMT Chief Executive, said,

After the worst year in a lifetime, the growth in production for commercial vehicles during 2021 is extremely welcome. Despite a plethora of challenges, manufacturers have remained operational throughout the year. The sector isn’t out of the woods yet, however, and challenges remain heading into 2022. Support will be necessary to ensure the supply chain can overcome ongoing semiconductor-related shortages as well as measures to ensure energy costs do not rise to an extent that it significantly undermines competitiveness.

Notes to editors

1. 1933: 65,508 – 2020: 66,116

2. Full year production 2015-2019 average – 85,956