Which reasons led a company that manufactures automotive components to embark on an air quality project?

At Grupo Antolin, before the pandemic, we had detected the need to keep the vehicle cabin clean and safe in environmental terms, which is why we began to work on a technological exploration that would allow us to respond to these requirements. Initially, filtration was identified as the most mature and safe technology for air purification. This technology presented some limitations that had to be overcome in order to adapt it to the interior of the automobile. That was our challenge!

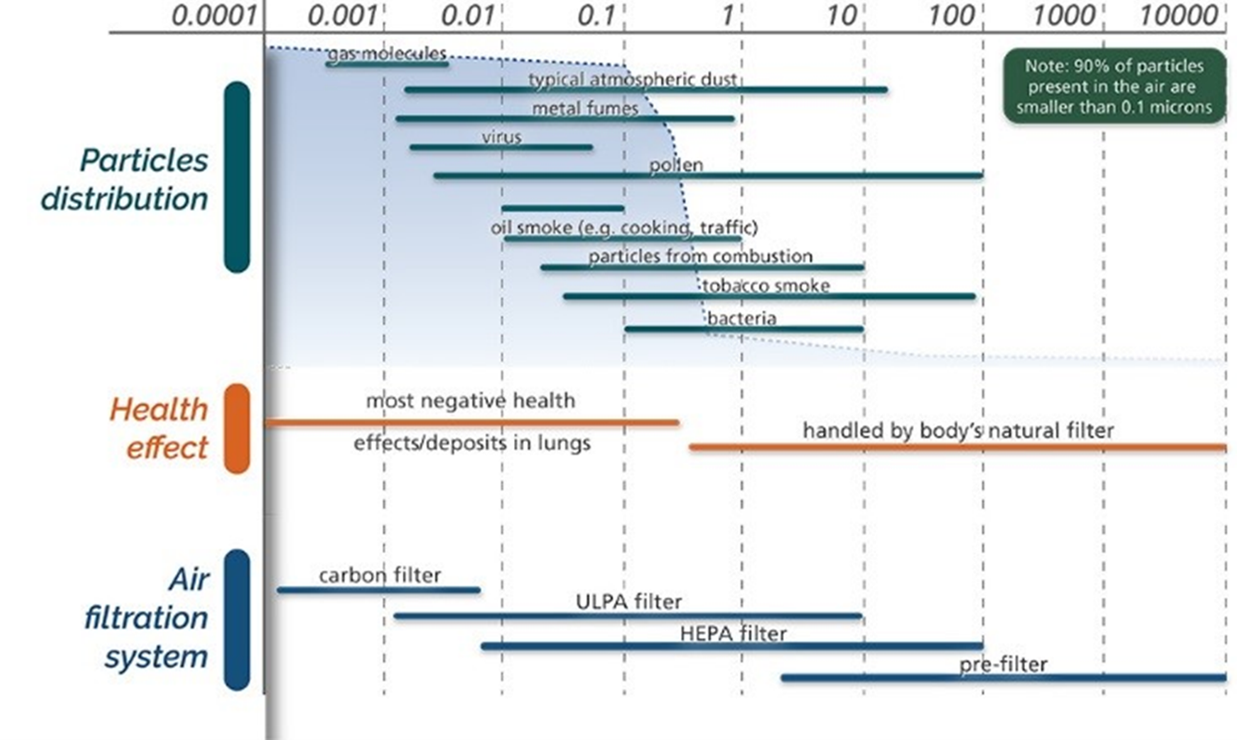

Nowadays there are plenty of devices oriented to air purification on the market. As a general rule, these devices have either a very limited filtration capacity or a design that prevents their integration into our environment. Truly efficient purifiers are mostly very noisy, bulky, heavy, and present high energy consumption. The main reason is the increased air resistance caused by the filter element when trying to increase the filtration efficiency. In general, the greater the filtration capacity, the greater the power of the fan motor that forces the air to pass through, which implies a direct increase in noise and energetic consumption. In addition, this equipment lacks the remarkable ability to detect and collect information on airborne pollutants with an aerodynamic diameter greater than 2.5 microns.

As a result of these analyses, Grupo Antolin decided to develop a more efficient device together with the company ZONAIR3D, a specialist in air purification systems. Based on their extensive knowledge in the field, the team from Grupo Antolin’s Corporate Innovation Department worked together on the development of a high-performance air purifier. The CTC (Centro Tecnológico de Componentes de Cantabria) also joined the project to support us with their fluid dynamics studies.

Our solution makes use of the main filtration mechanisms in a multi-stage design. The device has high-efficiency pre-filtration and filtration stages using screening, inertial impact, interception, and diffusion mechanisms, and an intermediate gas filtration stage using adsorption, providing the system with very high retention efficiency over the entire range of contaminants. In addition, the high-efficiency filtration stage follows the ULPA standard which requires the removal of 99.9995% of the most penetrating particles.

This solution is completed with the design of an impulsion stage formed by two parallel elements and an internal mechanical design that maximizes the fluid dynamic behavior of the system. The system also has a UV disinfection stage for the inactivation of biologically active components, viruses and bacteria, retained in the high-efficiency filter.

Illustration 1: Pollutant classification, effects, and filtration strategies.

Furthermore, the system has a proprietary monitoring solution and algorithm developed specifically to maximize the system’s detection capabilities. The gas sensors detect the presence of specific elements through oxidation reactions. On the other hand, optical sensors measure the size of airborne particles that cross their measurement area. Thanks to the in-house development and combination of these sensors, the Corporate Innovation Management team has been able to increase the sensing capabilities and to develop an automatic operating mode. This automatic operating mode evaluates the air quality by combining the two parameters to adjust the impulsion system.

An air purifier adapted to our automobiles

The results of the work carried out by Grupo Antolin have been very satisfactory. The device developed is an air purifier for the interior of the vehicle with the capacity to purify up to 20 m3/h of air working at maximum power, being able to retain and inactivate particles of less than 0.1 to 10 microns, including viruses, bacteria, allergens, and dust. In addition, it also retains other elements harmful to health such as volatile organic compounds, odors, fumes, nitrogen oxides, and sulfur oxides. The purifier has a multi-stage filtration process for superior efficiency, real-time particulate matter, and gas sensors, and additionally uses ultraviolet radiation to ensure filter sanitization and safety.

In terms of design, it exhibits optimized size and weights, and it is made out of polymeric materials validated for automotive use. It presents a LED indicator to indicate the air quality based on the measurements of its sensors and its own algorithm. It allows operation in automatic mode in addition to the manual function in which you can choose between high or low power operation. It also includes a filter replacement LED indicator and a connection to a smartphone app.

Illustration 2: Final design of aftermarket purifier.

For Grupo Antolin, the realization of this project has been a first step towards the application of this technology, as well as the acquisition of knowledge before moving on to a model integrated into the vehicle, providing additional functionality that today’s cars do not have. There are still some barriers to overcome to make this technology fully integrable into vehicles, and these challenges are what drive us to continue researching to develop a highly efficient and fully integrated model in the vehicle of the future, which is getting closer every day.