Thought LeadersAlan BanksUK Lightweight Innovations Manager Ford Motor Company

Thought LeadersAlan BanksUK Lightweight Innovations Manager Ford Motor CompanyAZoM speaks with Alan Banks from Ford Motor Company about the significance of using lightweight materials in vehicles to improve fuel efficiency and the sustainability of the industry.

Please can you introduce yourself and your professional background?

My name is Alan Banks. I am the UK Lightweight Innovations Manager at Ford Motor Company. I have been at Ford for approximately 39 years and I have a first-class BEng and an MSc. I also Chair the Board at Composites UK, Chair the Lightweighting Strategy Group for the UK Auto Council, and Chair the Vehicular Composites Leadership Forum.

How significant is the weight of a vehicle to fuel consumption, and how much can be saved by transitioning to more lightweight materials?

My work is based on our commercial vehicles, and whilst fuel economy is a critical to-buy enabler for our customers, we look at payload efficiency and total cost of ownership as the biggest metrics for our customer base. As we transition towards zero-emission vehicles, CO2 reduction is of critical importance.

In this arena where the vehicle doesn’t generate CO2 in its run time, we need to be aware of our embedded CO2 footprint. So having a clear plan for sustainability and understanding our responsibilities to our customers and the environment go hand in hand in my day-to-day life.

Alongside your role as Lightweight Structures Supervisor at Ford Motor Company, you are also team leader of the Composite Lightweight Automotive Suspension System (CLASS) and Composite Hybrid Automotive Suspension System Innovative Structures (CHASSIS) projects. What are these projects, and what do you hope to achieve with them?

These projects were predominantly research-based to determine how we can affordably deploy high-end lightweight materials at scale. The CLASS project enabled us to learn about mixed material designs and how these materials interact during manufacture and in service. This project led directly to the CHASSIS project. This reduced the weight of 3 major structural suspension members by over 46% (31.9kg) and only used a production process capable of mass production.

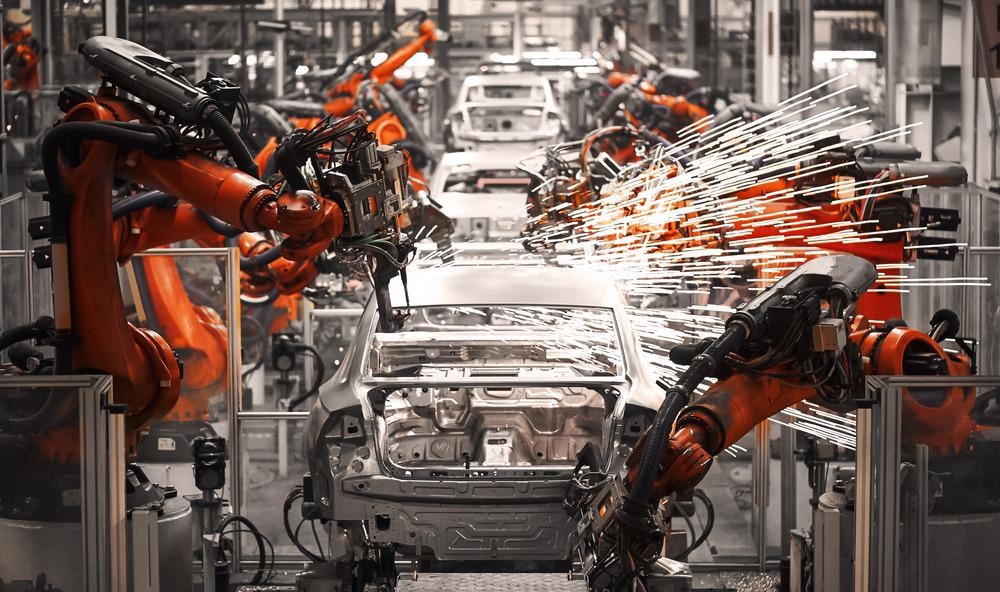

Image Credit: Jenson/Shutterstock.com

These projects have found success in other applications that are being instigated in our future platforms. The most important lesson we learned was not to be afraid of how to process mixed materials. By putting the right material in the right place, we can meet the demands of our customers sustainably and efficiently.

Could you describe some examples of lightweight advanced materials that could make a significant difference in optimizing vehicle performance, both now and in the future?

I think that the ‘now’ is more than adequately covered by the advances in aluminum processing and composite materials. However, we shouldn’t lose sight of steel. Steel is still going to be the material of choice for most OEMs due to its efficient cost/weight parameters. But steel is increasing in its research just as fast as the rest of the materials industry.

I talked about the right material in the right place and this is especially true of steel – advanced high-strength steel. I believe that it is entirely feasible to offer designs in lightweight steel with materials with a base strength of 1000MPA that are formable and weldable, reducing weight by as much as 25%. Plus, using a reduced gauge can mean cost neutrality. Lowering the weight, improving the performance, and reducing the cost without affecting recycling and sustainability aspects of the designs is a win-win-win-win. Plus we allow more payload to be carried by a single vehicle, reducing the burden on the world’s natural resources. This is far and away my biggest focus and keeps me coming to work.

Image Credit: Alex Neshitoff/Shutterstock.com

In the future, I would say advancements in nanotechnology will be coming to the fore. Graphene and carbon nanotubes are not science fiction – they are science fact. Ford has had great success in infusing graphene in some of our underhood components in the past, and this should continue. Graphene is very expensive but because you use so little of it (less than 0.1% volume typically), it can have tremendous benefits in weight, NVH, durability, and potentially cost. Graphene also has the ability to be functionalized to allow sensors in some critical structures for preventative maintenance. This could pay dividends in an autonomous future.

What steps is Ford taking to manufacture and recycle these materials in a green way?

Ford was the first major EOM to publish a sustainability report. This is now published yearly and really showcases the great work that we are doing for the environment. Of course, we realize that building machines that burn CO2 seems contrary to that ideal – but mankind has become very used to having on-demand services and products. We only have to look at the recent pandemic to see how fragile our supply chain can be and so we see it as our responsibility to further our products to meet our customer’s demands.

We have a purchasing demographic of the population who are more environmentally aware than ever before and they will demand that we take action. We could of course wait for legislation to make this happen, but at Ford we are taking a much more proactive approach. Even when the US pulled out of the Paris Climate Accord, Ford chose to stay in unilaterally – you will have seen our Chairman (Bill Ford) talking passionately about making Ford carbon neutral by 2050.

These aren’t just words – in Europe, we have committed to being all-in on electrification and we are aggressively pursuing this goal. And why? Because our customers demand it. As well as this, at the end of the life of our vehicles, we see the recycling, dismantling, and circularity of materials and components as a key step to developing better and robust solutions that will mean that nothing from a vehicle goes to landfill.

Upcycling is an area that I’m very keen to explore to turn waste into a valuable commodity. Our team in the US has recently conducted a study with Rice University to create graphene from waste plastic, and it’s this kind of innovation that will help us all in our push for circular sustainability.

You are participating in a talk at the Advanced Materials show at the NEC this month that considers how transportation lightweighting is both more sustainable and economical. Could you describe some of the key points you will be covering?

Affordable lightweighting is about encompassing scalability while enhancing our sustainability credentials. It is incredibly important that we as an industry tackle these issues together. We all have the same issue, we live on the same planet, and we all use the same resources. Collaboration I think will be key to success, not only for Ford but for the global economy. This is not a test that anyone should fail. We all share the responsibility to succeed.

Could you describe the relationship between efforts to implement lightweight materials and the shift toward greater electric vehicle manufacturing in the automotive sector?

Electric vehicles, like it or not, have added a huge amount of weight to our vehicles. More weight means more natural resources being used. This is bad enough for passenger cars, but for commercial vehicles, this detracts from payload efficiency. When people’s diving licenses are restricted to 3.5T for a Cat B license, this means a restricted payload and therefore more vehicles on the road using even more resources to manufacture. This isn’t a sustainable scenario.

Whilst it’s true that in Britain and the EU there is a driving license derogation up to 4.25T for electric vehicles, this is goods carrying vehicles only and is due to run out in 2023. Lotus founder Colin Chapman had a motto where he said ‘Just add Lightness’. This is a phrase on every email I send and I want people to have it in the forefront of their minds when they design their components.

How important are conferences like Advanced Materials for creating conversations and generating interest around advanced and lightweight materials research?

These events are where the real networking and collaborations take place. Whilst we coped virtually during the pandemic, I think everyone would agree that there is no substitute for face-to-face collaborations and networking. You get out of these events what you put in, and I am very excited to meet everyone.

About Alan Banks

Alan Banks is the Lightweight Structures Manager at Ford Motor Company. He started work at Ford in 1983 as an apprentice and his remit is to lead projects with light-weighting technologies and applications in design with mass production capability.

Alan Banks is the Lightweight Structures Manager at Ford Motor Company. He started work at Ford in 1983 as an apprentice and his remit is to lead projects with light-weighting technologies and applications in design with mass production capability.

He led the Composite Lightweight Automotive Suspension System (CLASS) project, which won the 2018 JEC World Automotive Application Innovation award and the Composite UK Innovation Award winning Composite Hybrid Automotive Suspension System Innovative Structures (CHASSIS) project.

Alan has a First-Class Honours Degree and an MSc from the University of Bradford, is a Fellow and Chartered Engineer with the Institute of Engineering Technology and a Fellow of the Institute of Innovation and Knowledge Exchange, and a member of the Society of Automotive Engineers. He is Chairman of the Board for the Composites UK Trade Association, Chairman of the Vehicular Composites Group and the Chairs the Lightweighting UK Auto Council Strategy Group.

https://www.sae.org/publications/technical-papers/content/2022-01-0341/

https://www.sae.org/publications/technical-papers/content/2020-01-0777/

https://www.sae.org/publications/technical-papers/content/2019-01-1122/

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.