Sporty, emotional, efficient, and intelligent: the new Mercedes-Benz C-Class Stuttgart. “Upgrade your comfort zone” – Mercedes-Benz will reveal the new C-Class under this claim in a digital world premiere on the Mercedes me media platform on Tuesday, February 23rd, 2021 at 2:00 p.m. (CET). Markus Schäfer (Member of the Board of Management of Daimler AG… Continue reading @Daimler: “Upgrade your comfort zone”: Digital World Premiere of the new C-Class on Mercedes me media

Author: Daimler Official News

@Daimler: Production anniversary at Mercedes-Benz: 50 million passenger cars from the global production network

Stuttgart. Anniversary and premiere at Mercedes-Benz: The first new Mercedes-Maybach S-Class from Factory 56 is also the 50-millionth car from Mercedes-Benz to roll off the line in the global production network. “Mercedes-Benz has always been synonymous with luxury. That’s why I’m very proud of this very special production anniversary: Fifty million vehicles produced is a… Continue reading @Daimler: Production anniversary at Mercedes-Benz: 50 million passenger cars from the global production network

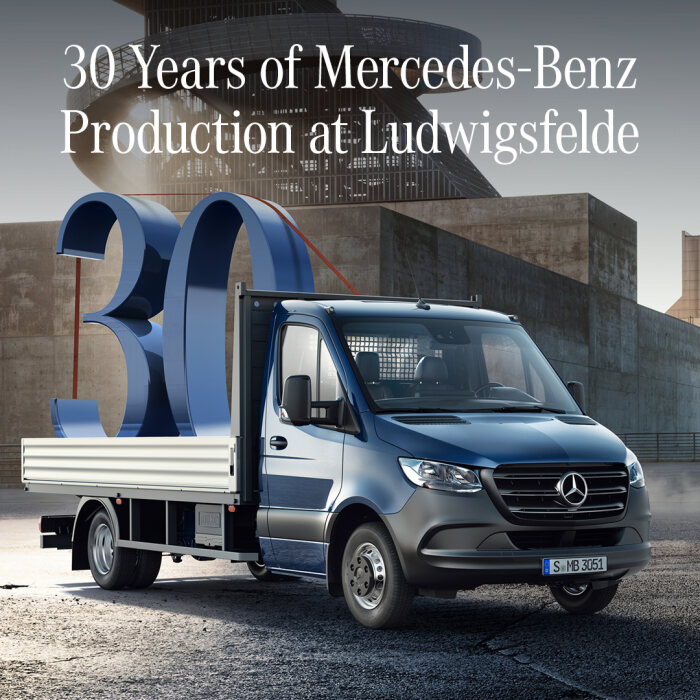

30 years under the banner of the three-pointed star – Mercedes-Benz plant in Ludwigsfelde celebrates a special anniversary

08.

February 2021

Ludwigsfelde, Germany

From truck to van – a fresh start after the fall of the wall Economic power and security for the region Changes in production through the years Ludwigsfelde, Germany – Exactly thirty years ago, an LN2 truck was the first Mercedes-Benz vehicle to roll off the production line in Ludwigsfelde, which is now Daimler's third largest van production plant in the world. Today, about 200 of the so-called open model series of the Sprinter (chassis, platform vehicle, tractor head) are manufactured daily, well over 50,000 per year. Over 820,000 vehicles of the brand with the star have now been produced at the Brandenburg plant and sold all over the world.

From truck to van – a fresh start after the fall of the wall

The truck with model designation LN2 led the way, rapidly followed by the first van, the T2, which was also built from 1991 until 1996. The T2 was followed by the Vario and finally the Mercedes-Benz Sprinter, the open model variants of which have been in production in Brandenburg since 2006. Currently, in Ludwigsfelde the third Sprinter generation with its derivatives the wind runner and the traction head are being produced. These form the basis for many different types of vehicle, for example ambulances, camper vans or refrigerated vans.

Economic power and security for the region

Three decades ago, the plant in Ludwigsfelde was one of the largest and therefore most important industrial employers in the region. Brandenburg's Prime Minister Dr Dietmar Woidke on the occasion of the anniversary: “What began 30 years ago has become a success story. I am glad that the former GDR vehicle construction in Ludwigsfelde was stabilised and expanded thanks to the entry of Mercedes-Benz after 1990. Ludwigsfelde is thus one of the success stories of German unity. With the traditional Stuttgart-based company, Brandenburg has a long-standing reliable and strong economic partner. The state government is aware of the current difficult situation of companies and their employees in times of the Corona pandemic. We are doing everything we can to ensure that the framework conditions continue to be good so that we can get off to a good start after the foreseeable end of the pandemic. And of course this also applies to the Sprinter production in Ludwigsfelde. Last summer I visited the factory. And I got a picture of the sprinter production under corona conditions with special protective measures. The commitment of the workforce and the high demands placed on the safety and health of the employees at the plant are impressive.”

In previous years, Mercedes-Benz Vans has invested a great deal in the future of the plant, a total of around one billion euros. “The plant is a mainstay in our current worldwide production network,” said Dr Ingo Ettischer, Head of Production for Mercedes-Benz Vans. “We have already set the course in recent years to set up Ludwigsfelde for the future, particularly in view of the transformation to electric and connected vans. Plus there's the increasing digitisation of production. All of this requires innovative power, expertise and a professional approach – as the Ludwigsfelde team impressively proves every day.”

The most important capital: the team

Today, more than 2,000 people work for Mercedes-Benz in Ludwigsfelde, most of them on the production of the latest generation of the Sprinter. “There is one decisive factor that determines our sustainable success here at the plant and that is our team,” said the Plant Manager and Managing Director of Mercedes-Benz Ludwigsfelde GmbH, Dr Markus Keicher. “Only with the right people can you produce vehicles successfully over such a long period of time. You need a skilled and practised team that gives its very best every day so that vehicles can be produced to customers' specifications and hold their own on the roads of the whole world – for years and years.”

Changes in production through the years

Production has changed considerably over the past thirty years and the factory has been constantly developed. Thanks to its efficiency and numerous innovations, Ludwigsfelde is now one of the Group's most modern sites. In recent years, digitisation has increased considerably in the production of Mercedes-Benz Vans, in the form of driverless transport systems, exoskeletons, or the use of RFID chips in logistic processes.

Additional quotes:

Changes in production through the years

Steffen Seidel, Head of Series Preparation at the Ludwigsfelde plant, has been at the works for almost 30 years and said of changes in production: “When we built the first vehicles in 1991, the production plant looked very different from the way it does today. Most of the manual section of the tasks has been replaced to a large extent by a far greater degree of automation. Today we make considerably more than 200 vehicles per day in two shifts, something that would have been hard to imagine thirty years ago. This was made possible thanks to the innovative power of the staff, new production technologies, by improving the ergonomics at the workplace, and by constantly improving the series preparation. Here the latest methods of digitisation, parts manufacture, bodies for pre-series vehicles, and training methods for production staff are constantly being added to and improved. With it, highly complex and extremely challenging product start-ups, such as the various Sprinter generations, were successfully mastered at the Ludwigsfelde plant. I personally am fascinated by the field of tension between increasingly sophisticated product developments and putting them into practice in our factory in an increasingly digitalised world.”

Combined growth – Ludwigsfelde and Mercedes-Benz

Andreas Igel, the Mayor of Ludwigsfelde, said on the subject of Mercedes-Benz's roots in the area, “We have achieved a lot together, and the history of the town of Ludwigsfelde is inseparably linked with the success story of the factory – not just over the past thirty years. The factory has contributed to making Ludwigsfelde an attractive location for its inhabitants over the past decades, and to helping the town and the region to develop constantly. We as a town are proud of this long-standing, reliable partnership and we would like to congratulate the management and the entire staff on thirty years of 'Mercedes-Benz Made in Ludwigsfelde'! We will do everything we can to further strengthen this partnership in the interests of the employees and of the people of the region,” promised Igel.

Press Contact

Thomas C. Rosenthal

Global Technology Communications Mercedes-Benz Vans – Future Transportation & adVANce

thomas_christian.rosenthal@daimler.com

Tel: +49 176 30933075

Silke Walters

Manager Global Business Communications Mercedes-Benz Vans

silke.walters@daimler.com

Tel: +49 176 30909308

Press Contact Overview

Media

Download

Pictures (14)

Documents (1)

Media Contact (2)

Filter

Show thumbnails

Show list

Slideshow

Settings

Preview

Do you really want to delete the data record?

Please wait a moment …

Please wait a moment …

Please wait a moment …

Please wait a moment …

20C0303_001

Legend

:

Brandenburg's Prime Minister Dr. Dietmar Woidke visited Mercedes-Benz Ludwigsfelde in 2020. In the picture (from left to right): Dr. Dietmar Woidke, Prime Minister of brandenburg; Dr. Markus Keicher, Site Manager Mercedes-Benz Ludwigsfelde.

Release date

:

Feb 8, 2021

21C0072_001

Legend

:

30 years Mercedes-Benz from Ludwigsfelde

Release date

:

Feb 8, 2021

21C0072_002

Legend

:

30 years Mercedes-Benz from Ludwigsfelde

Release date

:

Feb 8, 2021

21C0072_003

Legend

:

Mercedes-Benz Ludwigsfelde: Aerial view of the plant site in 2020

Release date

:

Feb 8, 2021

21C0072_004

Legend

:

Mercedes-Benz Ludwigsfelde: Aerial view of the plant site in 2020

Release date

:

Feb 8, 2021

21C0072_005

Legend

:

Mercedes-Benz Ludwigsfelde company sign

Release date

:

Feb 8, 2021

21C0072_006

Legend

:

Production at the Mercedes-Benz Ludwigsfelde plant

Release date

:

Feb 8, 2021

21C0072_007

Legend

:

Production at the Mercedes-Benz Ludwigsfelde plant

Release date

:

Feb 8, 2021

21C0072_009

Legend

:

Celebration on the occasion of a million commercial vehicles from Ludwigsfelde in 2010

Release date

:

Feb 8, 2021

21C0072_010

Legend

:

Line sequence of the first Mercedes-Benz at the Ludiwgsfelde plant on 2/8/1991 (Werner Niefer, Chairman of the Board of Management of Mercedes-Benz AG 1989-93, Manfred Stolpe, Prime Minister of the State of Brandenburg 1990-2003)

Release date

:

Feb 8, 2021

21C0072_011

Legend

:

Mercedes-Benz Ludwigsfelde: Aerial view of the plant site in 1997

Release date

:

Feb 8, 2021

21C0072_012

Legend

:

The founding of the Mercedes-Benz plant 30 years ago was celebrated in Ludwigsfelde at the south gate on February 01, 2021.

Release date

:

Feb 8, 2021

21C0072_013

Legend

:

30 years Mercedes-Benz from Ludwigsfelde

Release date

:

Feb 8, 2021

21C0072_014

Legend

:

30 years Mercedes-Benz from Ludwigsfelde

Release date

:

Feb 8, 2021

Loading

Mercedes-AMG Motorsport expands its international GT involvement and will also be competing with customer teams in the DTM

04.

February 2021

Affalterbach

Mercedes-AMG Motorsport is expanding its globally successful GT programme and will also be represented in the German DTM race series in 2021. In the inaugural season of the reframed series, multiple customer teams will be competing for points, victories and titles with cars from the traditional brand from Affalterbach. Like in previous years, the Mercedes-AMG Customer Racing schedule also includes numerous further high-quality race series and international motorsport classics: in the process, the 24-hour races at the Nürburgring and in Spa are fixed elements on the calendar, just like the rounds of the GT World Challenge Europe, the Intercontinental GT Challenge and, of course, the ADAC GT Masters, all of them with high-class field. During their activities around the globe, the international customer teams are supported by a strong driver line-up.

Mercedes-AMG will be present with customer teams in the 2021 DTM High-class races and series on the GT calendar for Mercedes-AMG Motorsport Top drivers in action for Mercedes-AMG Customer Racing Teams worldwide Mercedes-AMG Motorsport keeps pushing ahead with the expansion of its international customer sports programme and will be present in the DTM in 2021. In the reframed sprint series that will also be held with cars to GT3 regulations from this season, starting off at Monza in mid-June, AMG intends to add to its successful DTM history with eleven drivers’ titles, 14 teams’ titles and seven manufacturers’ titles. The current planning involves the participation of multiple Customer Racing Teams to compete for points with their Mercedes-AMG GT3s.

Next to that, an equally strong focus by Mercedes-AMG in the 2021 season is on numerous highlight series and endurance racing classics in which this year, several customer teams will be competing for success with extended support from Mercedes-AMG again: next to the legendary 24-hour races at the Nürburgring and Spa-Francorchamps, these also include the endurance races of the Intercontinental GT Challenge (IGTC) as well as the races of the GT World Challenge and the Nürburgring Endurance Series (NLS). The ADAC GT Masters is also playing a central role again in Mercedes-AMG Customer Racing’s planning: in the super sports car league with its traditionally strong entry, all four customer teams that were involved there last year managed to score race wins. At the end of the season, no other manufacturer had more victories to its tally.

Excellent driver line-up for worldwide customer sports activities

With the Dubai 24-hour race and the historic 1-2 in the season-opening round of the IMSA WeatherTech SportsCar Championship at Daytona, this year’s Mercedes-AMG Motorsport GT programme has already had a highly successful start. For the numerous further challenges this year, the line-up of the drivers who will be out to race with customer teams at circuits worldwide has now been finalised. Once again, it assembles some of the best-known and most successful drivers in international GT racing. Like in the previous year, Maximilian Buhk (GER), Maro Engel (GER), Maximilian Götz (GER), Thomas Jäger (GER), Raffaele Marciello (ITA) and Luca Stolz (GER) will primarily be racing the Mercedes-AMG GT3 this season.

For the current motorsport season, additions to the line-up include Daniel Juncadella (ESP). The former DTM driver already raced for points with the Mercedes-Benz SLS AMG GT3 back in 2015. Most recently, the 29-year-old Spaniard raced a Mercedes-AMG GT3 in the 2020 ADAC TOTAL 24h-Rennen Nürburgring where he was among the fastest drivers at the Nordschleife straight away following a long absence from GT racing. Moreover, Jules Gounon (FRA) is a member of the promising line-up: in 2017, the now 26-year-old scored six class podium results for the AKKA ASP Customer Racing Team in the Blancpain GT Series. In the same season, Gounon also claimed the ADAC GT Masters championship crown and secured the overall win in the 24-hour race at Spa-Francorchamps.

Further experienced drivers will be providing additional support for the renowned driver team in selected races such as the 24-hour race at the Nürburgring or rounds of the Intercontinental GT Challenge.

Expansion of the sim racing involvement

At the virtual race tracks, the Mercedes-AMG GT3 will have an increased presence this season as well. Last year already, many teams and drivers achieved esports success with the virtual GT3 from Affalterbach. Now, Mercedes-AMG Motorsport is putting further GT aces from real-world motorsport behind the wheels of the sim rigs. Adam Christodoulou, Daniel Juncadella and Raffaele Marciello, who are all competing in real-world motorsport as well, will be competing for success in selected sim racing events and will be supported for the first time by Daniel Morad (CAN), an established sim racing professional.

Stefan Wendl, head of Mercedes-AMG Customer Racing: “This year, we can rely on an excellent driver line-up again. I am convinced that, like this, we are supporting our teams in the best possible way for their worldwide racing activities and can be in a position to win at any time. The goal is to win championship titles on all continents and to run at the front in the 24-hour highlights in particular, as we were already able to prove especially at Daytona. To the strongly contested series in which we were already present last year, the DTM will now be added, another series with a long tradition to expand our international involvement. From my perspective, we are in a very good position for all the upcoming challenges with the Mercedes-AMG GT3 and the Mercedes-AMG GT4, both in terms of our goals at the real-world race tracks and concerning our involvement in sim racing.”

Press Contact

Jochen Übler

Manager Global Communications Mercedes-AMG

jochen.uebler@daimler.com

Tel: +49 7144 302-92470

Press Contact Overview

Media

Download

Pictures (14)

Documents (2)

Media Contact (1)

Filter

Show thumbnails

Show list

Slideshow

Settings

Preview

Do you really want to delete the data record?

Please wait a moment …

Please wait a moment …

Please wait a moment …

Please wait a moment …

MercedesAMGCustomerRacing_GT_Programm_2021_01

Legend

:

Mercedes-AMG Motorsport will be participating in the 2021 DTM.

MercedesAMGCustomerRacing_GT_Programm_2021_02

Legend

:

#88 Mercedes-AMG GT3, AKKA ASP Team

MercedesAMGCustomerRacing_GT_Programm_2021_03

Legend

:

#2 Mercedes-AMG GT3, GetSpeed Performance

MercedesAMGCustomerRacing_GT_Programm_2021_04

Legend

:

Mercedes-AMG GT3s, Haupt Racing Team

MercedesAMGCustomerRacing_GT_Programm_2021_05

Legend

:

Simracing, Mercedes-AMG GT3

MercedesAMGCustomerRacing_GT_Programm_2021_06

Legend

:

Maximilian Buhk (GER)

MercedesAMGCustomerRacing_GT_Programm_2021_07

Legend

:

Maro Engel (GER)

MercedesAMGCustomerRacing_GT_Programm_2021_08

Legend

:

Maximilian Götz (GER)

MercedesAMGCustomerRacing_GT_Programm_2021_09

Legend

:

Jules Gounon (FRA)

MercedesAMGCustomerRacing_GT_Programm_2021_10

Legend

:

Thomas Jäger (GER)

MercedesAMGCustomerRacing_GT_Programm_2021_11

Legend

:

Daniel Juncadella (ESP)

MercedesAMGCustomerRacing_GT_Programm_2021_12

Legend

:

Raffaele Marciello (ITA)

MercedesAMGCustomerRacing_GT_Programm_2021_13

Legend

:

Daniel Morad (CAN)

MercedesAMGCustomerRacing_GT_Programm_2021_14

Legend

:

Luca Stolz (GER)

Loading

@Daimler: All systems go for the compact electric car from Mercedes-EQ: The EQA is now available for order

Environmental bonus of 9000 euros makes the EQA particularly attractive in Germany Stuttgart. EQA is the name of the entry-level model from the all-electric world of Mercedes-EQ. Prices in Germany start at 47,540.50 euros[i] for the EQA 250 (combined power consumption: 15.7 kWh/100 km; combined CO2 emissions: 0 g/km)[ii] with 140 kW. Other variants for… Continue reading @Daimler: All systems go for the compact electric car from Mercedes-EQ: The EQA is now available for order

@Daimler: Daimler plans separation

Intention to split Daimler’s industrial businesses and establish two independent pure-play companies Spin-off and separate listing of Daimler Truck planned Significant majority stake to be distributed to current Daimler shareholders Intention to rename Daimler as Mercedes-Benz at the appropriate time Mercedes-Benz will be the world’s pre-eminent luxury car business, committed to leading in electric drive… Continue reading @Daimler: Daimler plans separation

@Daimler: Welcome on board: Karin Rådström takes over management of Mercedes-Benz Trucks

Karin Rådström took up her position as Member of the Board of Management, Daimler Truck AG, responsible for Mercedes-Benz Trucks, today. Rådström most recently has been responsible for sales and marketing at Scania as a member of the Executive Board. “We are very pleased to welcome Karin to our global leadership team. She has a… Continue reading @Daimler: Welcome on board: Karin Rådström takes over management of Mercedes-Benz Trucks

Over the air: updates become upgrades at Mercedes-Benz

28.

January 2021

Stuttgart

Stuttgart. Mercedes-Benz is further expanding the possibility of keeping programs and systems in the vehicle up to date through updates over the air (OTA). What started with Mercedes-Benz vehicles in the USA in 2013 is standard for the MBUX infotainment system today. Some twelve million over-the-air updates have now been performed. Many MBUX customers around the world can visit the Mercedes me Store to book and add additional services and optional extras. With over-the-air updates, completely new features enter the vehicle that is already with the customer: updates turn into upgrades.

Updating the navigation maps stored in the vehicle began with the E-Class in 2016. What previously required the insertion of a data medium such as a DVD, or a workshop visit, now takes place automatically over the air every three months, assuming the customer has activated this service in the Mercedes me Portal.

“Over-the-air updates are not new for us. Thanks to our many years of experience and many successfully run OTA campaigns over the years, our customers always have the latest software in the vehicle. With 'over the air', it is not just software updates that we can deliver to vehicles already sold, but also features which haven't even been invented yet. OTA enables the vehicle to become a more and more effective tool for the customer as time goes on”, says Georges Massing, Head of Digital Vehicle & Mobility at Mercedes-Benz AG.

How does over the air work in concrete terms? As soon as a new update is available from Mercedes-Benz, a message is shown in the central display; the download and installation of the update run in the background. Important note: the user then has to agree again explicitly to the activation. In this way, the vehicle is always up to date with software. To transmit the data, Mercedes-Benz relies on mobile radio technology and the communication module installed in the vehicle – this is the most secure way.

A further option for an updated and improved user experience is the additional booking of new functions in the Mercedes me Store: Smartphone Integration such as CarPlay or Android Auto, In-Car Office or the digital radio DAB+ for optimum radio reception are available there. And the best thing of all: services whose subscription has expired can also be renewed quickly and easily online via the Mercedes me Store.

However, some features and services will not even require an update in the vehicle. The reason being that MBUX is a hybrid system and draws upon data and software stored in the vehicle as well as upon information stored in the cloud. This applies, for example, to the voice assistant “Hey Mercedes”. It constantly learns new words and phrases through exchange with the cloud. Questions such as “Where is the nearest pizza place?” or “How did the national football team do today?” naturally also rely on the latest information in the cloud.

In addition, the latest traffic and weather information is constantly transferred to the vehicle, including associated data such as the snow depth in ski areas.

Currently, A-Class customers who have been using MBUX since 2018 are now receiving the additional streaming services TIDAL and Amazon Music, as well as access to the Mercedes me Store in MBUX, while in specific languages MBUX is switching to use the familiar form of “you”. In this way, updates become upgrades.

Depending on the age of the vehicle there are more functions available for downloading which are already on board more recently built models. The A-Class is shown as an example here (the dates will differ for other model series with MBUX):

Produced from … to …

MBUX functions

… 03/2018 to 10/2018

… 10/2018 to 06/2019

… 06/2019 to 06/2020

… 06/2020 to 12/2020

Online music: TIDAL

x

on board

ex factory

on board

ex factory

on board ex factory

Mercedes me Store

x

x

on board

ex factory

on board ex factory

The familiar form of “you” (certain countries)

x

x

x

on board ex factory

Online music: Amazon Music

x

x

x

x

x= OTA update possible

The next step in the update strategy of Mercedes-Benz comes with the new S-Class. Its electronics architecture allows over-the-air updating of more than 50 control units in the vehicle and of the entire MBUX system, including the central display, without a workshop visit.

Press Contact

Georg Walthart

Communications Connected Car & Mercedes me

georg.walthart@daimler.com

Koert Groeneveld

Head of Global Product and Technology Communications

koert.groeneveld@daimler.com

Tel: +49 160 8614747

Press Contact Overview

Media

Download

Pictures (3)

Videos (4)

Documents (1)

Media Contact (2)

Filter

Show thumbnails

Show list

Slideshow

Settings

Preview

Do you really want to delete the data record?

Please wait a moment …

Please wait a moment …

Please wait a moment …

Please wait a moment …

21C0039_002

Legend

:

Over the air update: Mercedes-Benz vehicles are constantly learning “over the air”. In the meantime, around 12 million Mercedes vehicles Over the Air have been updated. Updates become upgrades

Release date

:

Jan 28, 2021

21C0039_003

Legend

:

Over the air update: Mercedes-Benz vehicles are constantly learning “over the air”. In the meantime, around 12 million Mercedes vehicles Over the Air have been updated. Updates become upgrades

Release date

:

Jan 28, 2021

21C0039_004

Legend

:

Over the air update: Mercedes-Benz vehicles are constantly learning “over the air”. In the meantime, around 12 million Mercedes vehicles Over the Air have been updated. Updates become upgrades

Release date

:

Jan 28, 2021

Loading

@Daimler: Personnel changes in the Mercedes-Benz Trucks production network: Sven Gräble takes over from Gerald Jank

Sven Gräble will take over as Head of Mercedes-Benz Trucks Operations at Daimler Truck AG and will thus be responsible for the global production network of Mercedes-Benz Trucks. In this role, he succeeds Gerald Jank, who will retire on January 31, 2021, after more than 32 years with the company. In the global production network… Continue reading @Daimler: Personnel changes in the Mercedes-Benz Trucks production network: Sven Gräble takes over from Gerald Jank

@Daimler: Preliminary results for the financial year 2020 significantly above guidance and market expectations

Stuttgart, Germany – Daimler completed the financial year of 2020 in a challenging environment with a very strong fourth quarter, in particular with regard to Industrial Free Cash Flow. All divisions contributed to this success. Mercedes-Benz Cars and Vans exceeded key financial metrics of the financial year 2019. Industrial Free Cash Flow, Daimler Group EBIT,… Continue reading @Daimler: Preliminary results for the financial year 2020 significantly above guidance and market expectations