14.

September 2019

Nice

Press Contact (2)

Willem Spelten

Head of MBC Brand, Design & Special Media Communications

willem.spelten@daimler.com

Tel: +49 (0)711 17-75847

Fax: +49 (0)711 17-79099473

Lars Zeppenfeld

Manager Design Communications

lars.zeppenfeld@daimler.com

Tel: +49 (0)711 17-75834

Fax: +49 (0)711 17-91437

Download

Filter

Settings

Do you really want to delete the data record?

Please wait a moment …

Please wait a moment …

Please wait a moment …

Please wait a moment …

The highlights: Design Essentials III – The main points at a glance

Nice, Sep 14, 2019

Interview with Gorden Wagener: “Our design showcases the luxury of the brand.”

Nice, Sep 14, 2019

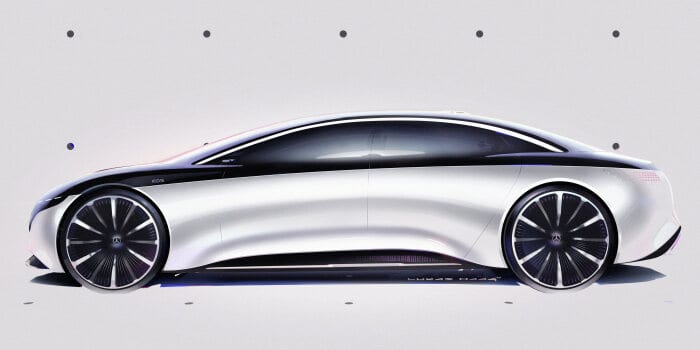

Exterior design: Seamless, digital and electric

Nice, Sep 14, 2019

Interior design: Blending the digital and analogue worlds

Nice, Sep 14, 2019

UI/UX design: Maximum simplicity paired with sensuous experiences

Nice, Sep 14, 2019

International Design Centres: Working on the future

Nice, Sep 14, 2019

Product design yesterday

Nice, Sep 14, 2019

Product design today

Nice, Sep 14, 2019

Product design tomorrow

Nice, Sep 14, 2019

Loading