× {{dictionary[‘Added to your cart’]}} × {{dictionary[‘CART WARNING’]}} {{dictionary[‘Sorry, your cart is currently full. Please remove ‘]}} × {{dictionary[‘Cookie message and title’]}} × Pagination Warning! Sorry, Please add a number less than maximum pages {{dictionary[‘User Licence – pop up text’]}} You have been detected as being located in: {{userLang}} A media site housing news, photo… Continue reading FUTURE JAGUAR AND LAND ROVER VEHICLES WILL HELP CURE MOTION SICKNESS

Category: Official Press Release

Wed 31 Oct 2018

PRODUCTIONISATION OF ADVANCED MODULAR PASSENGER AUTONOMOUS SEATING (PAMPAS)

The Productionisation of Advanced Modular Passenger Autonomous Seating (PAMPAS) project is a feasibility study funded through the European Union’s Horizon 2020 research and innovation programme to prove the economic potential for the mass production of Gordon Murray Design’s innovative light-weight automotive seats.

Gordon Murray Design recently revealed its new seat innovation – the iStream® lightweight seat, which incorporates glass or recycled carbon-fibre composite bonded to a tubular frame to achieve a dramatic 30% weight saving vs a conventional modern seat. The building of composite car seats has traditionally been expensive due to the unsuitability of the composite manufacturing process for mass production, but the revolutionary iStream manufacturing process overturns this convention, utilising a composite sandwich panel structure and metallic frame combination, which costs no more than a conventional car seat.

To ensure the already technically proven seating system can enter into series production as a commercially viable proposition, major deliverables from the PAMPAS project will be to undertake a study to establish market trends and growth expectations of seating systems within the automotive industry and to investigate and assess manufacturing business model options.

*** Key advantages of iStream lightweight seat:

30% weight saving vs conventional modern seat.

iStream lightweight composite structure (glass or carbon).

Full four-way adjustment and fold-flat mode.

ECE R17 Luggage retention.

Professor Gordon Murray, Chairman of Gordon Murray Design said: “Gordon Murray Design is pleased to announce the Productionisation of Advanced Modular Passenger Autonomous Seating (PAMPAS) project as an important further development of the revolutionary iStream® manufacturing technology and is another example of a new innovation that can be implemented in a cost-effective and robust manner, appropriate for mass production”.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 827005.

-Ends-

Notes to Editors:

Gordon Murray Design’s iStream lightweight seat is currently on display at the Advanced Engineering show at the NEC between 31st October to 1st November 2018 on Stand M80 in Hall 3/3A.

About Gordon Murray Design Limited

Gordon Murray Design is a visionary design and engineering company with its headquarters in Shalford in Surrey, plus R&D and manufacturing facilities in Dunsfold. It was established in 2007 with a focus on developing an innovative and disruptive manufacturing technology trademarked iStream®, and has since built a global reputation as one of the finest automotive design teams in the world.

The company’s unique approach and truly creative thinking enables Gordon Murray Design to deliver complete car programmes in a highly efficient and innovative way from concept and design, through to prototype and development for production.

About iStream

Rather than the traditional method of combining hundreds of panels of stamped metal, iStream uses tubular metal with 10 – 15 structural composite panels. iStream Superlight® is the ultimate automotive lightweighting technology as it maximises the iStream approach by using cored honeycomb carbon fibre composite and an aluminium frame to save almost 50% in weight against a standard stamped metal chassis.

iStream is an acronym for iS = Stabilised; T = Tube; R = Reinforced; E = Exo-frame; A = Advanced; M = Manufacturing.

www.istreamtechnology.co.uk

About iStream lightweight seat

***Advantages of the iStream lightweight seat:

iStream lightweight composite structure (glass or carbon)

Full four-way adjustment and fold-flat mode

30% weight saving vs conventional modern seat

Satisfies all applicable European automotive requirements (UN ECE), including luggage retention requirements

Ultra-low tooling and developments costs

Flexibility of design through low cost tooling

Low part count

Simple, high-speed assembly

Suitable for low and high-volume applications

Can achieve low seating position

Excellent package performance

Anti-submarining design

Competitive piece cost

Patent protected

Enquiries:

For further information please contact Sarah Smith, Communications Officer at Gordon Murray Design Limited sarah.smith@gordonmurraydesign.com +44 (0)1483 484700.

DOWNLOADSDownload Release

Plant opens for electric air conditioning compressors: MAHLE strengthens its systems competence in electric vehicles

Press releases

Press archives

Media service

Publications

Press contact

Home

Press

Press releases

Plant opens for electric air conditioning compressors: MAHLE strengthens its systems competence in electric vehiclesStuttgart, October 31, 2018 – MAHLE has opened its first production plant for electric compressors. MAHLE will manufacture e-compressors for international automobile manufacturers at the production location in Balassagyarmat/Hungary and has already obtained several customer projects. Series production will start in 2019.

Presse releaseDownload [PDF; 43 KB] First MAHLE production line for e-compressorsElectric compressors remove the link between air conditioning systems and combustion enginesSeveral customer projects have already been wonCompressors are the heart of air conditioning systems—and the e-compressor will remove the link between air conditioning systems and combustion engines. Its role in the air conditioning of electric vehicles is therefore critical. “Electric compressors are of major strategic importance to MAHLE, because they enable us to build on our position as a complete systems provider in the field of air conditioning for electric vehicles too,” explains Dr. Jörg Stratmann, Chairman of the Management Board and CEO of the MAHLE Group. MAHLE also develops and produces the necessary electric drives as well as electronics and software.

The plant in Balassagyarmat will be particularly important when it comes to production rollout. “This location will help to further strengthen our existing market position,” adds Bernd Eckl, Member of the Management Board of the MAHLE Group and responsible for the Thermal Management business unit. At the same time, the opening of the production plant is a green light for the additional e-compressor production locations that will follow.

With the consistent implementation of its dual strategy—the further optimization of the internal combustion engine on the one hand and the simultaneous development of solutions for the widespread adoption of e-mobility on the other—MAHLE is instrumental in shaping the future of mobility as a key player in the automotive industry.

About MAHLEMAHLE is a leading international development partner and supplier to the automotive industry as well as a pioneer for the mobility of the future. The MAHLE Group is committed to making transportation more efficient, more environmentally friendly, and more comfortable by continuously optimizing the combustion engine, driving forward the use of alternative fuels, and laying the foundation for the worldwide introduction of e-mobility. The group’s product portfolio addresses all the crucial issues relating to the powertrain and air conditioning technology—both for drives with combustion engines and for e-mobility. MAHLE products are fitted in at least every second vehicle worldwide. Components and systems from MAHLE are also used off the road—in stationary applications, for mobile machinery, rail transport, as well as marine applications.

In 2017, the group generated sales of approximately EUR 12.8 billion with about 78,000 employees and is represented in more than 30 countries with 170 production locations. At 16 major research and development centers in Germany, Great Britain, Luxembourg, Spain, Slovenia, the USA, Brazil, Japan, China, and India, around 6,100 development engineers and technicians are working on innovative solutions for the mobility of the future.

For further information, contact:MAHLE GmbH

Margarete Dinger

Corporate Communications/Public Relations

Pragstraße 26–46

70376 Stuttgart/Germany

Phone: +49 711 501-12369

margarete.dinger@mahle.com

Annual report

This was our year 2017

Download

[PDF; 5087 KB]

Key figures

[PDF; 1464 KB]

Annual report website

MAHLE Performance

Our customer magazine

More

DENSO Announces Full Acquisition of EASE Simulation, Inc.

Searching for your content…

No results found. Please change your search terms and try again.

DENSO Announces Result of Interim Dividend and the Revision of Year-end Dividend Forecast

Searching for your content…

No results found. Please change your search terms and try again.

Statement: Reflash

October 31, 2018 , Auburn Hills, Mich. – FCA US LLC is voluntarily recalling an estimated 86,053 vehicles in the U.S. to reflash a powertrain controller. These vehicles may – in rare instances – exhibit engine stall during deceleration, most often while slowing to a stop. If a stall occurs under these circumstances, the engine may… Continue reading Statement: Reflash

Solid-State Battery Breakthrough: Fisker Inc.’s Scientists File Patents on Superior Energy Density Tech, Shattering Conventional Thoughts on EV Range and Charge Times

Fisker’s scientists, including the co-founder of global battery tech pioneer Sakti3, filed patents this week on flexible, superior energy density solid-state batteries.

Breakthrough technology will enable dramatically longer ranges of more than 500 miles on a single charge and charging times as low as one minute – faster than filling up a gas tank.

Automotive applications anticipated to be production grade ready from 2023 onwards. • Fisker’s solid-state batteries will feature three-dimensional electrodes with 2.5 times the energy density of lithium-ion batteries.

LOS ANGELES (November 13, 2017) – Fisker Inc., designer and manufacturer of uniquely stunning electric vehicles complemented with some of the longest EV ranges on earth, has filed patents this week – under a non-publication request – on flexible solid-state battery technology to challenge conventional thought on vehicle battery energy density, range, charging times and manufacturing costs.

Fisker’s scientists have reached an early breakthrough in solid-state technology. The wider team includes the co-founder of solid-state battery technology pioneer, Sakti3 – a first inventor of the seminal patents. Implications for Fisker’s vehicles beyond 2023 – as well as the larger EV industry as a whole – are significant. The patent includes claims over novel materials and manufacturing processes that are critical in achieving the required energy density, power and cost targets that are paramount for the widespread use of electric vehicles.

REVOLUTIONARY SCIENCE. MULTIPLE INDUSTRY FIRSTS

Current limitations in solid-state technology include low electrode current density, limited temperature ranges, limited materials availability, high costs and non-scalable manufacturing processes. Early results show that Fisker’s solid-state technology enables the construction of bulk three-dimensional solid-state electrodes with 25 times more surface area than flat thin-film solid-state electrodes and extremely high electronic and ionic conductivities – enabling fast charging and cold temperature operation. As a result, Fisker’s battery delivers 2.5 times the energy density of typical lithium-ion batteries – with the potential of costing one third of the 2020 projected price of those batteries due to advances in materials and manufacturing.

Several failure modes affect solid-state batteries, including low power and low rate capability due to high contact resistance and low ionic mobility in the layered electrode structures. Delamination issues due to volume changes and residual stresses during charge/discharge processes; dendrite penetration and stability vs. metallic lithium electrodes; and low ionic diffusion, particularly in low temperature climate due to solid-state material limitations, are also roadblocks. With the newly announced technology, Fisker’s scientists are addressing these technical bottlenecks. Figure: Fisker solid-state technology is capable of constructing bulk three-dimensional solid-state electrodes with 25 times more surface area than flat thin-film solid state electrodes and extremely high electronic and ionic conductivities – enabling fast charging and cold temperature operation.

Fisker anticipates the technology may be ready for automotive applications post 2023. Such long lead times are due to the lack of supply chains with particular raw materials and appropriate manufacturing tools, as well as established quality procedures for materials repeatability. Once the technology is fully validated, the battery will deliver a vehicle range of more than 500 miles on a single charge, and charging times as low as one minute – allowing technology to bypass the internal combustion engine and push the automobile into mass electrification. Fisker is in active discussions with various industrial groups around potential non-automotive partnerships – with the possibility of battery applications that may be commercialized much earlier than 2023.

Fisker’s flexible solid-state electrode construction will enable batteries with versatile voltage and form factors. They may be wound in cylindrical cells with higher voltage output, allowing usage of current tooling and machinery for battery packs – in addition to lesser cell-to-cell connections, thermal management and safety requirements. This further reduces battery system costs.

THE FISKER EMOTION LUXURY ELECTRIC FOUR-DOOR SEDAN: CES 2018 LAUNCH

The much-anticipated 2018 launch of the Fisker EMotion luxury electric vehicle at the Consumer Electronics Show will showcase a proprietary battery module with advanced thermal management using 21700 NCM cells from LG Chem. The company has been simultaneously working on proprietary technology that will enable charging for a 127-mile range in nine minutes. Fisker’s solid-state battery and extreme fast charging technologies will be on full display at the vehicle’s launch at CES.

“Our aggressive vision for the entire EV and automotive industry, not just for Fisker Inc., revolves around making the impossible, possible – and this global solid-state battery breakthrough is reflective of our utmost seriousness in making that vision a reality,” said Henrik Fisker, chairman and CEO of Fisker Inc. “It used to be about the efficiency of the gasoline engine. Now, it’s all about who breaks the code and smashes the barriers to future battery technologies that will enable mass market electrification. Our scientists have been working tirelessly to deliver. We’ve done it, and this is just the beginning.”

“This breakthrough marks the beginning of a new era in solid-state materials and manufacturing technologies,” said Dr. Fabio Albano, VP of battery systems at Fisker Inc. “We are addressing all of the hurdles that solid-state batteries have encountered on the path to commercialization, such as performance in cold temperatures; the use of low cost and scalable manufacturing methods; and the ability to form bulk solid-state electrodes with significant thickness and high active material loadings. We are excited to build on this foundation and move the needle in energy storage.”

About Fisker Inc.

California-based Fisker Inc. is revolutionizing the automotive industry by developing the most emotionally stunning luxury electric vehicles complemented with the longest EV range on earth. The brainchild of EV pioneer and world-leading automotive designer, Henrik Fisker, Fisker Inc.’s mission is to set a new standard of excellence and performance in the electric vehicle industry – developing unique, high-performance electric vehicles with truly disruptive design and groundbreaking battery technology.

Topics:

Fisker News,

Fisker Solid State Battery,

Sustainability,

Innovation

Subscribe Here!

Recent Posts

Posts by Tag

Fisker News (7)

Innovation (7)

Autonomous Vehicles (4)

Fisker EVs (4)

Sustainability (4)

Emotion EV (3)

Fisker Solid State Battery (3)

Future (3)

Autonomous Electric Public Transportation (1)

ORBIT Electric Shuttle (1)

Safety (1)

Smart City (1)

See all

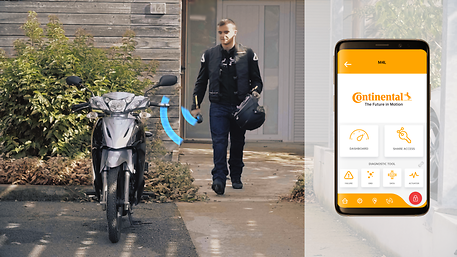

Connectivity Through Engine Control Units: New M4L module from Continental brings Bluetooth-capability to small motorcycles

“ Highly integrated management system for single-cylinder injection engines fulfills the newest exhaust standards and now also facilitates connectivity with the outside world Continental presents a new system alongside app functions such as keyless start technology and error diagnostics on the EICMA Regensburg, October 31, 2018. Motorcycle markets are undergoing a radical shift thanks to… Continue reading Connectivity Through Engine Control Units: New M4L module from Continental brings Bluetooth-capability to small motorcycles

AUDI AG after three quarters: key financials impacted by extraordinary factors

The third quarter of this year featured numerous adverse factors for the Audi Group: As expected, restrictions in the sales portfolio caused by the changeover to WLTP had an increasingly negative effect. At the same time, the densely packed program of phase-outs and ramp-ups in connection with the broadest model initiative in Audi’s history reached… Continue reading AUDI AG after three quarters: key financials impacted by extraordinary factors

JAGUAR LAND ROVER REPORTS SECOND QUARTER RESULTS FOR 2018/2019 FINANCIAL YEAR

× {{dictionary[‘Added to your cart’]}} × {{dictionary[‘CART WARNING’]}} {{dictionary[‘Sorry, your cart is currently full. Please remove ‘]}} × {{dictionary[‘Cookie message and title’]}} × Pagination Warning! Sorry, Please add a number less than maximum pages {{dictionary[‘User Licence – pop up text’]}} You have been detected as being located in: {{userLang}} A media site housing news, photo… Continue reading JAGUAR LAND ROVER REPORTS SECOND QUARTER RESULTS FOR 2018/2019 FINANCIAL YEAR