A slowdown in consumer electronics including smartphone sales is turning out to be a blessing in disguise for more than half a million Indians waiting for delivery of their cars.

A surge in demand for mobile phones, personal computers, televisions and appliances during the pandemic had led to a demand-supply mismatch for semiconductors, causing a shortage of the component for automakers and forcing them to cut down vehicle production for several months in the past one year.

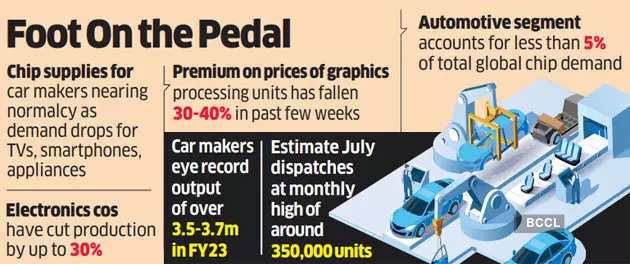

That situation is now changing. With consumers prioritising their expenses on consumer electronics amid high inflation, supplies of chips have improved for automakers. Vehicle makers have stepped up production and the industry estimates the July dispatches of cars and SUVs from factories to be the highest ever for a month at around 350,000 units; the previous peak of 334,000 units was recorded in October of 2020. With easing of the chip shortage, they also predict fiscal 2023 sales to be a new record high at 3.5-3.7 million passenger vehicles.

Tata Motors group chief financial officer PB Balaji said the slowdown in white goods industry helped improve supplies of chips and that he did not expect any major shortage concerns on domestic vehicle production due to the component’s shortage. On its British unit Jaguar Land Rover, the company is projecting its highest ever output in five quarters in July-September. Speaking at the automaker’s post-earnings call, Balaji also said he expected vehicle supply to improve every successive month.

Two-wheeler maker Bajaj Auto is likely to double its inventory, which is very low at present, in the next two months. Ahead of the key festivals, it aims to take the stock to an “optimum level” of six weeks. Bajaj Auto executive director Rakesh Sharma said in a recent media call that the supply situation had seen a dramatic improvement since July second half.

There is a fair amount of reason to think why the situation will ease every passing month, Tata Motors’ Balaji said. “The visibility of chip availability has improved quite significantly when compared to the early part of May and June, with production ramp-up happening in Q2. There is still some firefighting, but it is nowhere in the scale of challenge that we had even two-three months back.”

SMARTPHONE SHIPMENTS FALL

Consumer industry executives said amid weak demand for entry to mid-segment smartphones, laptops, smart televisions and appliances, companies had slashed production by up to 20-30% since May-June. They expect this to continue at least in August as well.

Godrej Appliances business head Kamal Nandi said the lead time for the availability of chipsets had progressively come down for them as well, from the peak of nine months a year ago to about three months now. “Most global economies are reporting a slowdown in electronic sales, so the supply situation has dramatically improved,” he said.

Chipsets are used across all segments of smartphones and laptops whose demand has fallen, while for appliances, it is mostly used in premium products. In smartphones, companies are holding unsold inventory of 10 weeks, more than double the usual, according to Counterpoint Research. Smartphone shipments have fallen 5% quarter-on-quarter in April-June, the research firm said.

Automotive accounts for just 5% of the global semiconductor demand, but that is one of the sectors where demand is still strong. Quarterly results of major global chip manufacturers suggest that demand for chips from consumer electronics has been softer. But plants are running at full capacity, thanks to the automotive and industrial segments.

Global chipset suppliers like Samsung, Intel and Qualcomm too have flagged lower demand, especially for entry level electronics. This can be gauged from the fact that the premium over maximum retail prices of graphic processing units — called the brain of gaming machine — has dropped by 30-40% in the past few months.

US chipmaker Intel’s revenue from the client computing segment — which caters to the desktop and notebook segment — fell 25% year-on-year in the April-June quarter due to a moderation in education, consumer and inventory reduction.

World’s largest chip manufacturing company, Taiwan Semiconductor, said supply was still short of its order book through the next half of 2022, with auto and industrial helping keep capacity full, even as there was a slowdown in demand from the consumer, PC and android smartphone segments.