NEW DELHI: Energy storage based on lithium-ion batteries can help India achieve its greenhouse gas mitigation targets, but the country has meagre lithium deposits and is heavily dependent on imports for its energy transition. That’s why it is important to have a reuse/recycle ecosystem for lithium-ion batteries within the country to minimise import dependence.

A circular economy for lithium batteries is all the more important because India, which is home to some of the most polluted cities on Earth, will be the third largest market for energy storage by 2040, behind China and the United States.

The circularity efforts will not only help in price recovery but also save India from geopolitical risks and environmental hazards arising from the mishandling of battery waste, such as water and soil contamination, and air pollution.

In order to channelise depleted batteries towards refurbishment or recycling, the environment ministry on August 24 notifi ed the Battery Waste Management Rules, 2022 for the management of various types of waste batteries, including lithium-ion batteries from electric vehicles, in an environmentally sound manner.

“Notification of these rules is a transformative step towards implementation of the announcement made by Prime Minister Narendra Modi in his address to the nation on Independence Day, 2021 to promote Circular Economy in full earnest,” said the ministry while notifying the new rules.

The 2022 rules provide for a mechanism of ‘extended producer responsibility’ (EPR) that makes manufacturers responsible for collecting waste batteries, ensuring their refurbishment or recycling, and the recovery of metals and other materials from them. Since the rules mandate the minimum percentage of recovery of materials, the move will bring new technologies and investment in the recycling and refurbishment industry and create new business opportunities.

“EPR, the principle in waste management globally, can really address both upstream as well as downstream issues of lithium-ion batteries (LIB). Introduction of an EPR-based framework for LIBs and LIB products with targets for collection and recovery can help in addressing some of the concerns,” said Ravi Agarwal, director, Toxics Link, one of the oldest Delhibased organisations working in the domain of hazardous waste management. Agarwal stressed on the need for cost-effective technologies to recycle lithium batteries in India. He said the recyclers need to have an economic motivation to sustain battery recycling.

Since India’s EV production will rely heavily on imports of lithium battery materials from China, a parliamentary standing committee on industry too had last year recommended that the government explore other sources of battery raw material to ensure their unhampered supply. “Increased collection and recycling effi ciency rates of lithium-ion batteries can mitigate dependence on imported materials and help retain the value of recovered materials within the country’s economy,” said Agarwal.

Under the Battery Waste Management Rules, 2022, the responsibility for the safe and environmentally sound management of used batteries is on the manufacturers and other stakeholders involved in dealing with waste batteries. Waste estimation is, however, a big issue at this stage because while India uses many types of lithium batteries, it has no database.

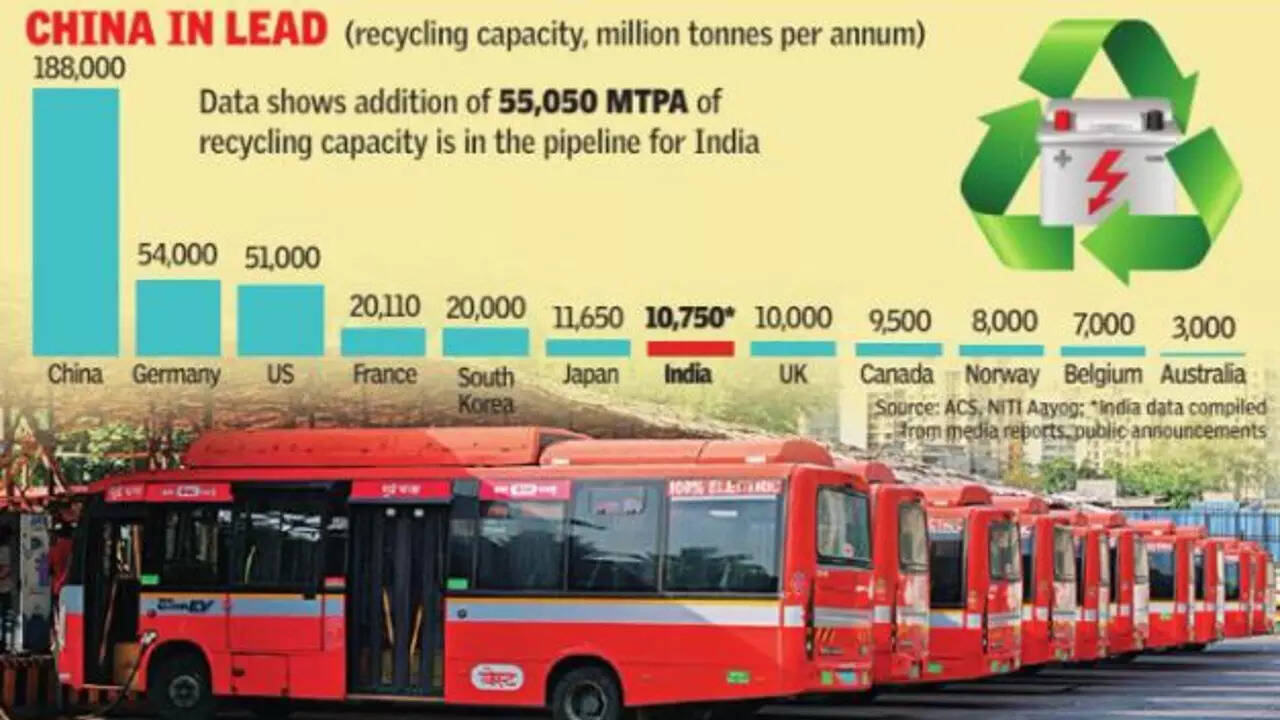

The government think tank NITI Aayog, in its report ‘Advanced Chemistry Cell Battery Reuse and Recycling Market in India’, has also emphasised the need for recycling, noting how the demand forraw materials is expected to magnify in India as the government is pushing for local manufacturing of lithium cells. But currently there are no local resources for some of the rare metals required for cell component manufacturing.

“Either the cell components or the raw materials must be imported to meet the demand if cell manufacturing takes off in the country. Recycling of batteries can generate a source for these rare metals. Using recycling technologies, 95% of metals can be recycled for use in manufacturing new batteries,” the Niti Aayog report says.

The new rules have replaced the Batteries (Management and Handling) Rules, 2001, which did not have specifi c provisions for managing waste from LIB used in EVs. Covering all types of batteries, including LIB, portable batteries, automotive batteries and industrial batteries, the 2022 rules are expected to promote setting up of new industries and entrepreneurship in collection and recycling/ refurbishment of waste batteries. Since the rules prescribe the use of a certain amount of recycled materials for making new batteries, they will help in reducing the dependency on new raw materials and save natural resources.

Under the new rules, environmental compensation will be imposed for non-fulfi lment of EPR targets, responsibilities and obligations. The funds collected as environmental compensation will be utilised in the collection and refurbishing or recycling of uncollected and non-recycled waste batteries.