It seems like just yesterday that Elon Musk ushered a gig worker in a spandex suit onto the Tesla AI Day 2021 stage and told us it was an robot — or at least probably would be one eventually. In the intervening 13 months, the company has apparently been hard at work, replacing the squishy bits from what crowd saw on stage with proper electronics and mechanizations. At this year’s AI Day on Friday, Tesla unveiled the next iteration of its Optimus robotics platform and, well, at least there isn’t still a person on the inside?

Tesla

Tesla CEO Elon Musk debuted the “first” Optimus (again, skinny guy in a leotard, not an actual machine) in August of last year and, true to his nature, and proceeded to set out a series of increasingly incredible claims about the platform’s future capabilities — just like how the Cybertruck will have unbreakable windows. As Musk explained at the time, the Optimus will operate an AI similar to the company’s Autopilot system (the one that keeps chasing stationary ambulances) and be capable of working safely around humans without extensive prior training.

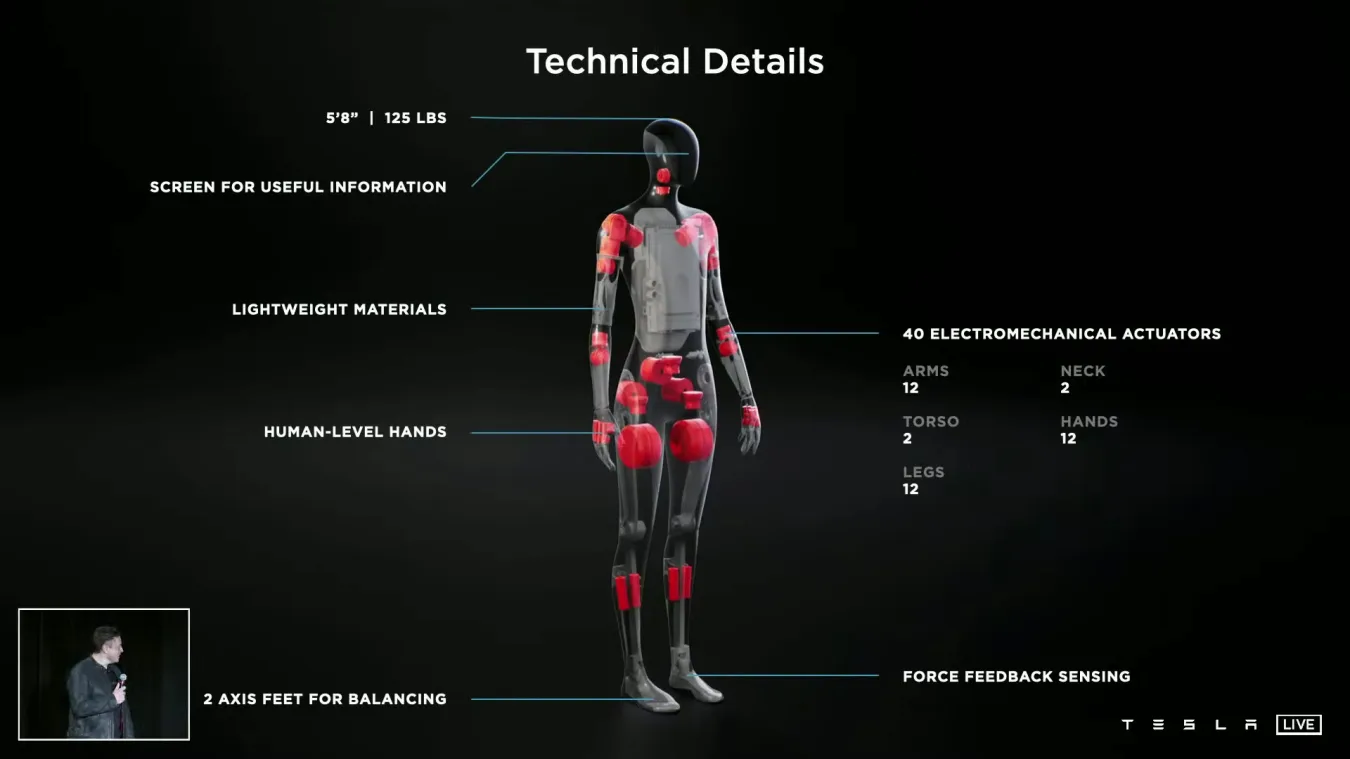

Additionally, the Tesla Bot would understand complex verbal commands, Musk assured the assembled crowd, it would have “human-level hands,” be able to both move at 5 MPH and carry up to 45 pounds despite standing under 6-feet tall and weighing 125 pounds. And, most incredibly, Tesla would have a working prototype for all of that by 2022, which brings us to today.

Tesla

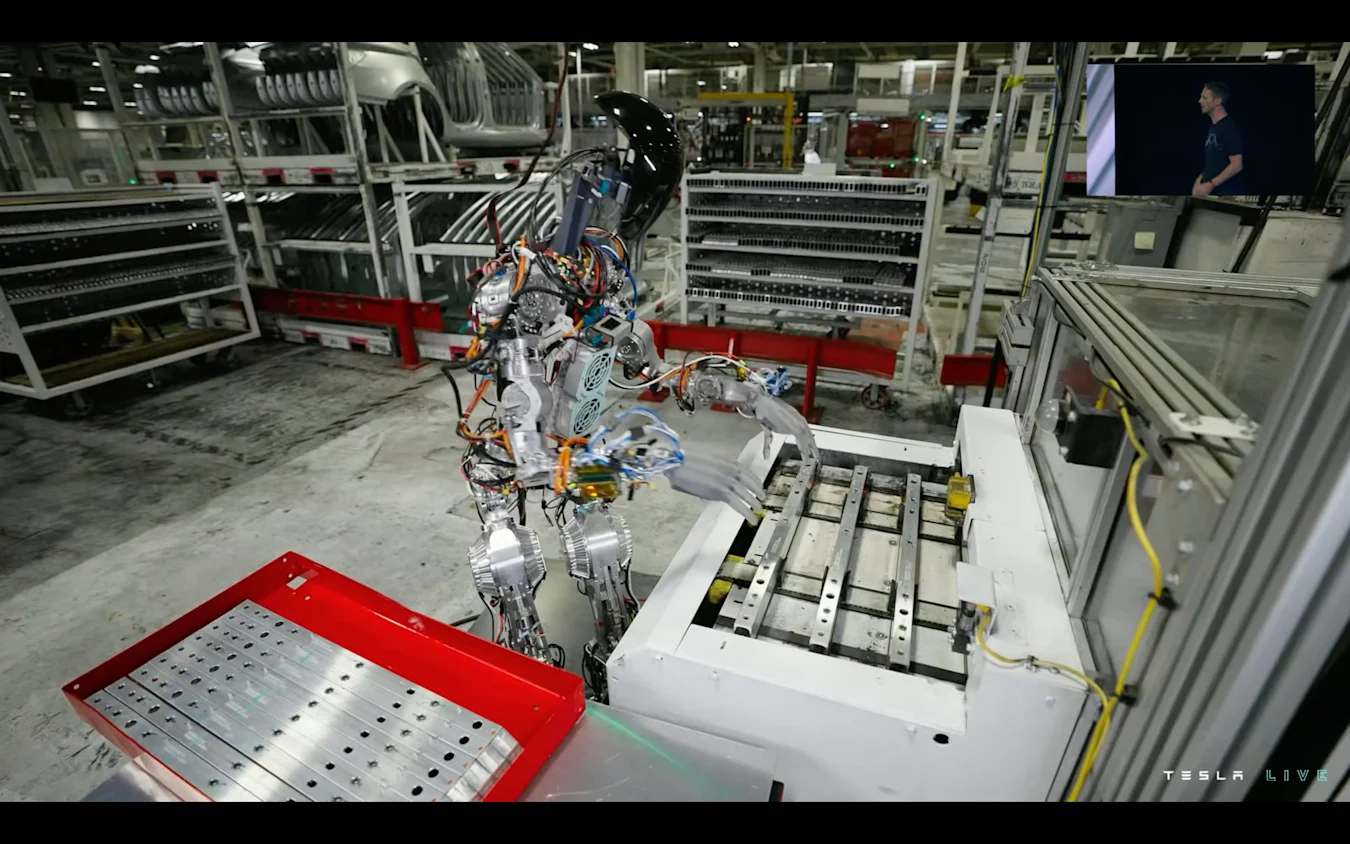

Kicking off the event, CEO Elon Musk was joined almost immediately on stage by an early development platform prototype of the robot — the very first time one of the test units had walked unassisted by an umbilical tether. Lacking any exterior panelling to reveal the Tesla-designed actuators inside, the robot moved at a halting and ponderous pace, not unlike early Asimos and certainly a far cry from the deft acrobatics that Boston Robotics’ Atlas exhibits.

Tesla

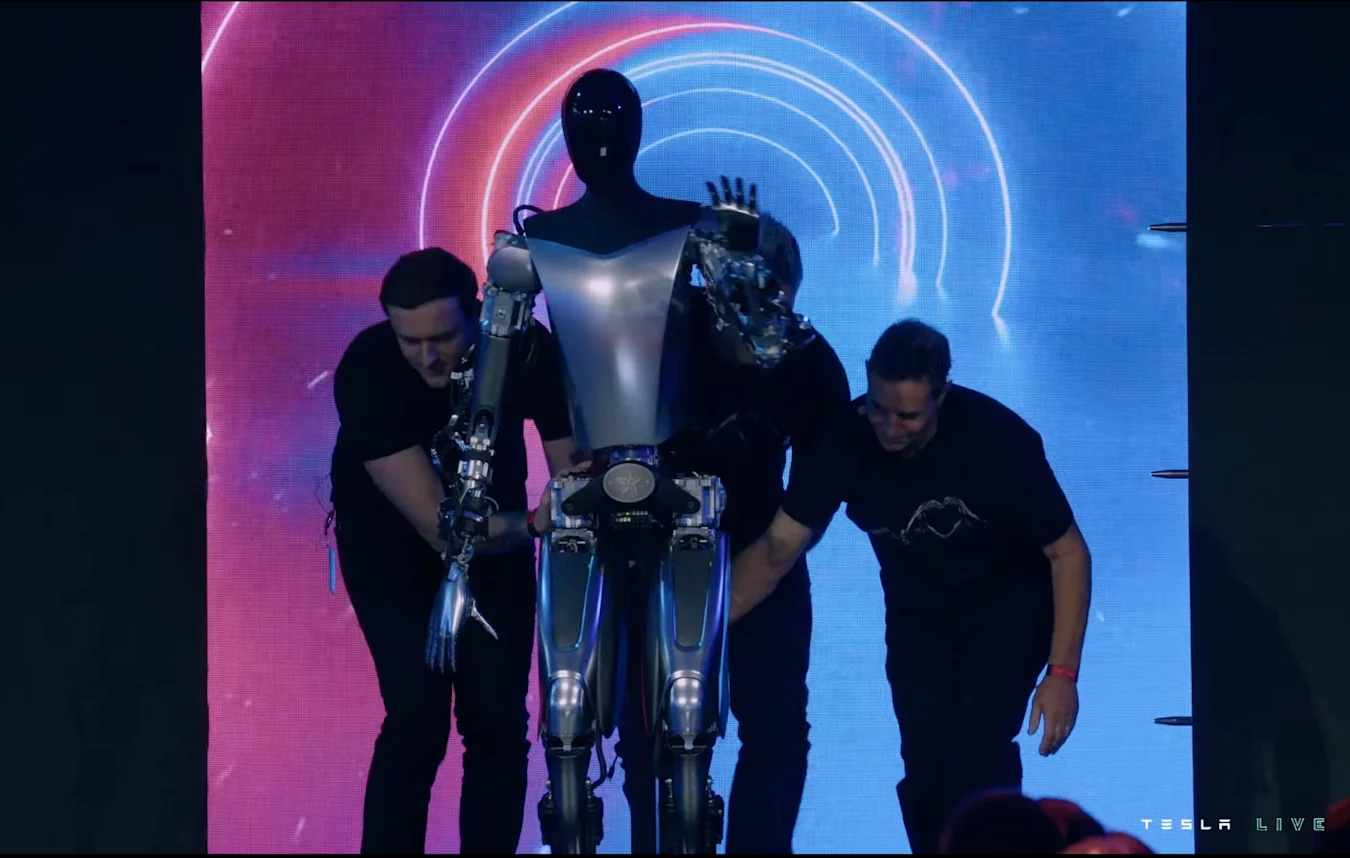

The Tesla team also rolled out a further developed, but still tethered iteration as well, pictured above. “it wasn’t quite ready to walk,” Musk said, “but I think we’ll walk in a few weeks. We wanted to show you the robot that’s actually really close to what is going to production.”

Tesla

“Our goal is to make a useful humanoid robot as quickly as possible,” Musk said. “And we’ve also designed it using the same discipline that we use in designing the car, which is to say… to make the robot at an high volume at low cost with higher reliability.” He estimates that they could cost under $20,000 when built at volume.

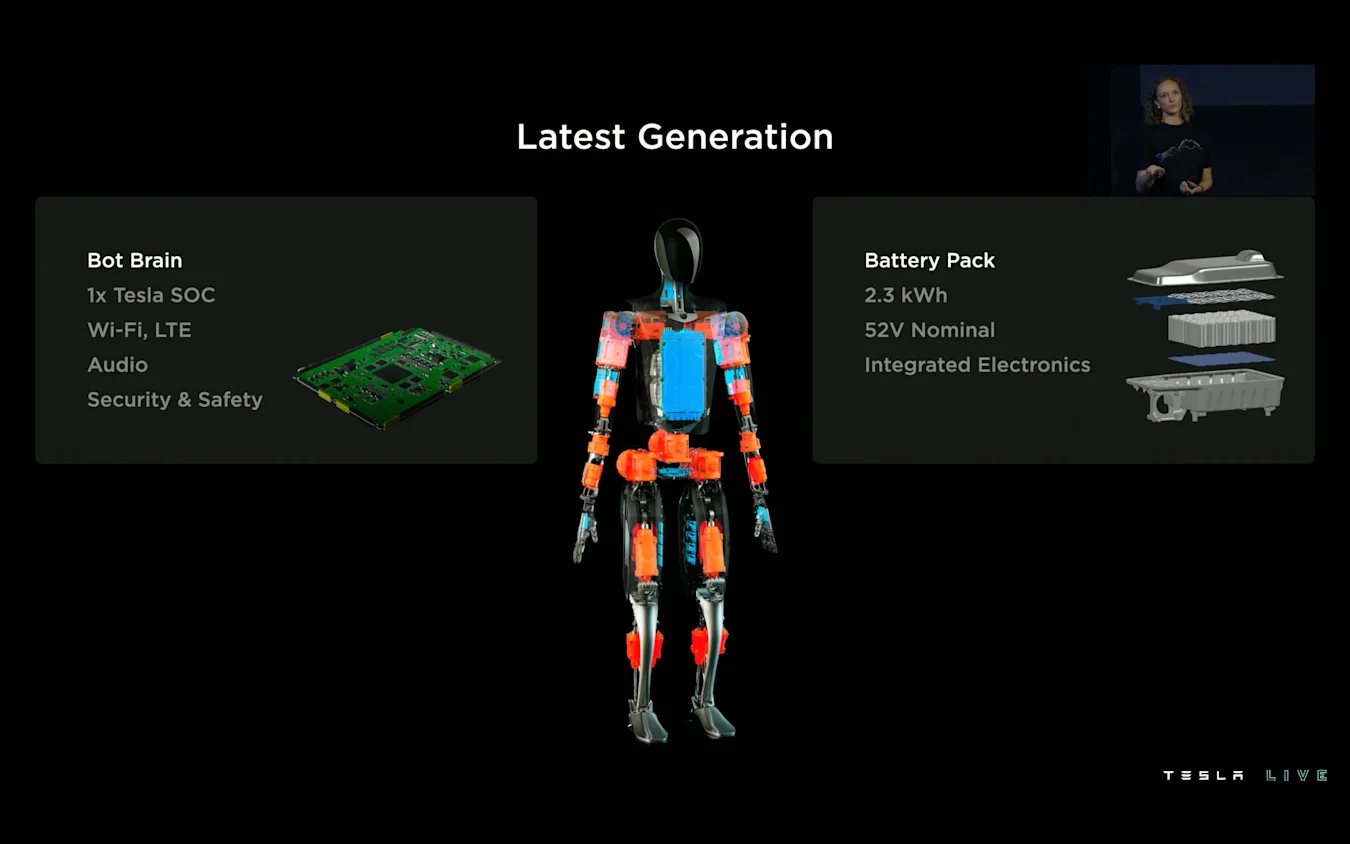

The Optimus will be equipped with a 2.3 kWh battery pack which integrates the various power control systems into a single PCB. That should be sufficient to get the robot through a full day of work, per Tesla’s engineering team which joined Musk on stage during the event.

Tesla

“Humans are also pretty efficient at somethings but not so efficient at other times,” Lizzie Miskovetz, a Senior Mechanical Design Engineer at Tesla, and a member of the engineering team explained. While humans can sustain themselves on small amounts of food, we cannot halt our metabolisms when not working.

“On the robot platform, what we’re going to do is we’re going to minimize that. Idle power consumption, drop it as low as possible,” she continued. The team also plans to strip as much complexity and mass as possible from the robot’s arms and legs. “We’re going to reduce our part count and our power consumption of every element possible. We’re going to do things like reduce the sensing and the wiring at our extremities,” Miskovetz said.

Tesla

What’s more, expensive and heavy materials will be swapped out with plastics that trade slight losses in stiffness with larger savings in weight. “We are carrying over most of our designing experience from the car to the robot,” Milan Kovac, Tesla’s Director of Autopilot Software Engineering said.

To enable the Optimus to move about in real world situations, “We want to leverage both the autopilot hardware and the software for the humanoid platform, but because it’s different in requirements and inform factor,” Miskovetz said. “It’s going to do everything that a human brain does: processing vision data , making split-second decisions based on multiple sensory inputs and also communications,” thanks to integrated Wi-Fi and cellular radios.

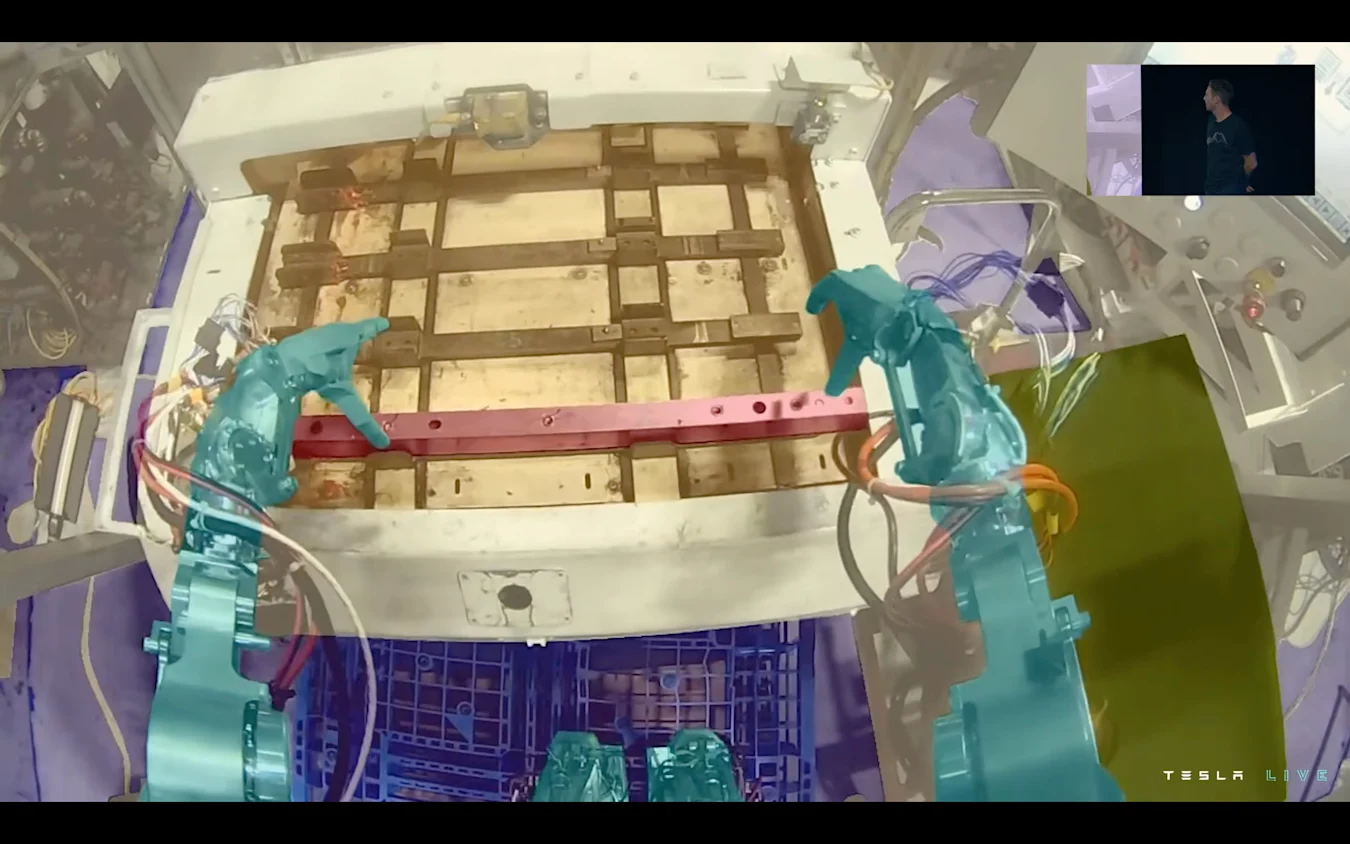

“The human hand has the ability to move at 300 degrees per second, as tens of thousands of tactile sensors. It has the ability to grasp and manipulate almost every object in our daily lives,” Kovac said. “We were inspired by biology. [Optimus hands] have five fingers and opposable thumb. Our fingers are driven by metallic tendons that are both flexible and strong because the ability to complete wide aperture power grasps while also being optimized for precision, gripping of small, thin and delicate objects.”

Tesla

Each hand will offer 11 degrees of freedom derived from its six dedicated actuators, as well as “complex mechanisms that allow the hand to adapt to the objects being grasped.” Kovac said. “We [also] have a non-backdrivable finger drive. This clutching mechanism allows us to hold and transport objects without having to turn on the hand motors.”

“We’re starting out having something that’s usable,” Kovac concluded, “but it’s far from being useful. It’s still a long and exciting road ahead of us.” Tesla engineering plans to get the enclosed, production iteration up and walking around without a tether in the next few weeks, then begin exploring more real-world applications and tangible use cases the Optimus might wind up in.

“After seeing what we’ve shown tonight,” Kovac said. “I’m pretty sure we can get this done within the next few months or years and maybe make this product a reality and change the entire economy.”

All products recommended by Engadget are selected by our editorial team, independent of our parent company. Some of our stories include affiliate links. If you buy something through one of these links, we may earn an affiliate commission. All prices are correct at the time of publishing.