Hyundai Motor Group has officially announced the setting up of a US-only $5.54 billion (Rs 45,943 crore) plant to establish itself as a global top tier electric vehicle OEM.

On October 25, the Korean carmaker held a ground-breaking ceremony for the new electric vehicle-only plant ‘Hyundai Motor Group Metaplant America (HMGMA)’ in Bryan County, Georgia, USA. Approximately $1 billion (Rs 8,293 crore) is anticipated to be invested by non-affiliated HMGMA suppliers in connection with the project in other locations.

Along with Georgia governor Brian Kemp, U.S. senators Raphael Warnock and Jon Ossoff, U.S. representative Buddy Carter, and U.S. Department of Commerce’s Don Graves, top company executives including chairman Chung Eui-sun, Hyundai Motor president Jae-Hoon Jang and Global Chief Operating Officer Jose Munoz were present at the event.

“Hyundai and the people of Georgia share many qualities: respect for our histories, ingenuity, creativity, and determination to make the world better for the next generation,” said Hyundai Motor Group Executive Chair Euisun Chung. “Today, our EVs are recognised as best in class, and with this partnership, we are determined to be the global leader in electrification, safety, quality, and sustainability. With the Hyundai Motor Group Metaplant America, we will continue to evolve beyond an automaker to the world’s leading mobility solutions provider.”

HMGMA will be built on a site of 11.83 million square metres with a scale capable of mass-producing 300,000 electric vehicles per year. Construction of the plant will begin in the first half of next year and mass production of EVs will begin in the first half of 2025. HMGMA is also expected to become a key base for Hyundai Motor Group to target the US electric vehicle market.

The US factory will produce EVs for all three brands of the Hyundai Motor Group – Hyundai, Kia and Genesis – with a flexible manufacturing system designed to produce multiple types of EVs to respond nimbly to local customer demands.

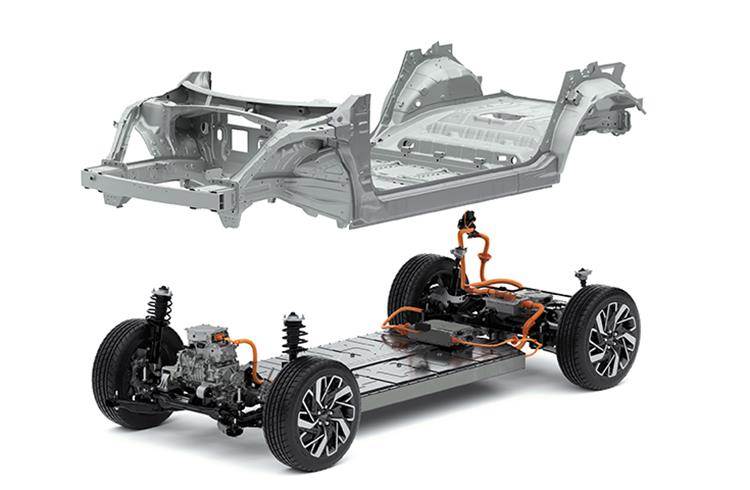

Electric-Global Modular Platform (E-GMP) platform will underpin cars of varying sizes from Hyundai, Kia and Genesis, ranging from hatchbacks to full-size SUVs.

Achieving economies of scale across US-based plants

Since the three Hyundai Motor Group production bases in the US are adjacent to each other, economies of scale can be expected in terms of parts procurement and supply chain management. HMGMA is about 420km away from Kia Georgia in the same state and about 510km away from Hyundai Motor America’s manufacturing subsidiary in Alabama (HMMA).

Hyundai Motor Group plans to operate HMGMA as a top-notch, future-oriented, innovative factory which will see the use of a manufacturing innovation platform empirically developed at it Singapore Global Innovation Center (HMGICS).

HMGICS’ manufacturing innovation platform includes demand-oriented artificial intelligence (AI)-based intelligent control system, eco-friendly low-carbon method to achieve carbon neutrality and RE100 (100% renewable energy use), human-friendly facilities that enable safe and efficient work. have.

Targeting sales of 3.23m EVs worldwide by 2030

The Korean carmaker plans to sell a total of 3.23 million EVs in the global market by 2030 and achieve a market share of about 12%. In the US, it aims to sell 840,000 EVs by 2030.

In the third quarter of this year (January to September), Hyundai Motor and Kia sold 47,095 EVs in the US, up 212.0% YoY. Hyundai sold 22,418 units of the Ioniq 5, a 142.3% increase while Kia also sold 24,677 EVs including the EV6 (17,564 units), resulting in a 322.2% increase in sales.

In the US, the proportion of EVs in Hyundai Motor Group’s total sales including internal combustion engines (4.3%, in the first three quarters of 2022) also increased significantly compared to January-September last year (1.3%). Hyundai Motor Group expects that EV sales in the US will grow more explosively when HMGMA starts full-fledged operation.

Strategic alliance with global battery company

Hyundai Motor Group plans to establish a stable local procurement system necessary for the manufacture and sale of electric vehicles, not only finished cars but also batteries. It plans to form a strategic alliance with a global battery company and establish a battery cell factory near HMGMA.

The joint battery plant will jointly develop and mass-produce battery products optimised for Hyundai Motor, Kia, and Genesis EVs, and HMGMA plans to produce and sell highly competitive electric vehicles with high efficiency, high performance and safety in a timely manner.

Hyundai Motor Group plans to accelerate the transition to electrification by building production bases for electric vehicles in Korea as well as in the United States. Hyundai Motor will build a new electric vehicle plant on the site of the driving test site in Ulsan plant, and Kia will build a PBV electric car plant in Autoland Hwaseong. Both will start mass production from 2025, the same time as HMGMA.

Using the three bases for electric vehicles in Korea and abroad as a stepping stone, the Hyundai Motor Group’s position in the global automobile market will rise to the next level, so that exports of domestic and overseas automobiles and electric vehicles can be expected to expand. In fact, last year, Hyundai Motor and Kia’s domestic production increased 12% compared to 2004, just before the operation of Hyundai Motor’s Alabama plant, and finished car exports also increased by 79% during the same period.

By 2030, Hyundai Motor (including Genesis) plans to build a line-up of 18 electric vehicles and Kia 13 EVs to produce 1.44 million electric vehicles annually in Korea alone.

ALSO READ:

Hyundai bullish on India EV growth story, plots 6 BEVs by 2028