Over the past two years, the global automotive industry has been through what could easily be termed as some of the most challenging years in its century-old history, what with Covid and the associated supply chain constraints derailing its smooth operations.

With the prolonged semiconductor shortage continuing to impact production forecasts at major automakers around the world, there is no better time for the industry to introspect and relook at the nature of its interconnectedness.

Though it is a highly-intertwined industry, there is a big lacuna in the sense that information flow between companies – for instance, an OEM and a supplier – is not the most transparent, due to the different ERP or enterprise resource planning systems which inhibit organised communication between one another. Procurement personnel at OEMs and suppliers are often seen relying on phone calls and informal messaging services to gather information on raw material availability and part visibility, to further determine production plans at their end.

It is here when blockchain – the decentralised information-flow technology – that has recently gained much acclaim in the finance-technology (fin-tech) space, particularly with the rise of cryptocurrencies, holds immense potential to be an enabler of supply chain collaboration in the automotive industry and improve real-time information transfer as well as transparency between companies.

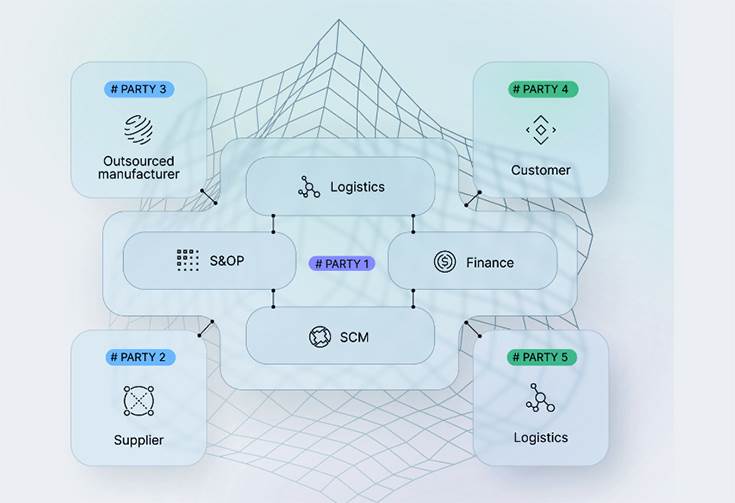

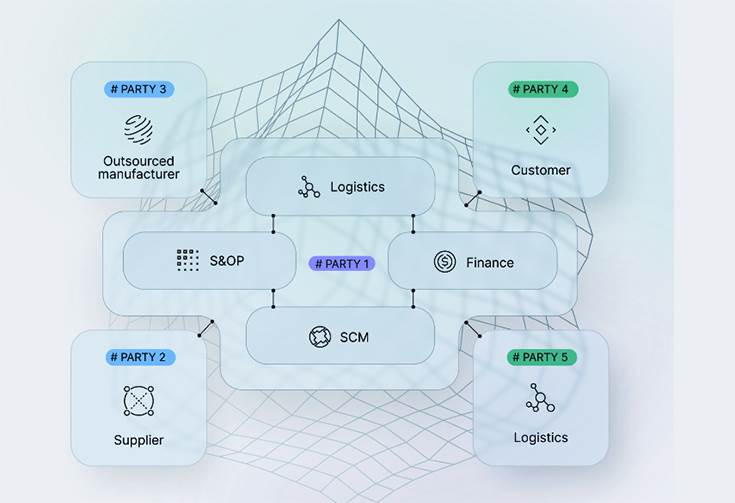

Using Blockchain and unifying all points of interaction into one single platform, Param Network enables companies to connect, transact and collaborate digitally in real-time with all their partners. It can readily connect with any ERP, SCM and EDI softwares and build multi-enterprise workflows rapidly.

Using Blockchain and unifying all points of interaction into one single platform, Param Network enables companies to connect, transact and collaborate digitally in real-time with all their partners. It can readily connect with any ERP, SCM and EDI softwares and build multi-enterprise workflows rapidly.

Digital collaboration the way forward

According to Vaideeswaran Sethuraman, founder, and CEO of Param Network, “Today, digital collaboration is imperative for enterprises; they never work in silos. There is a need for an extended-ERP environment that allows communication flow between one ERP system to another. Unfortunately, the entire backbone is missing when it comes to the automotive industry.”

“Any commerce involves a good supply chain, whether in the form of suppliers, dealers, logistics service providers or any other stakeholder,” he added.

In 2018, Sethuraman bootstrapped the Bengaluru-based Param Network that is working on developing Blockchain platform as an overlay to integrate different ERP systems between different companies, and enabling a seamless flow of information that drives transparency and real-time information visibility.

“Large ERPs are not designed to work in a collaborative fashion but blockchain is good in establishing peer-to-peer networking. While blockchain technology is working wonders when it comes to the fin-tech space, there have been a lot more use cases that have emerged in the last 3-4 years,” he said.

In the present scenario, where the industry lacks visibility of supplies week after week, any trusted stream of real-time information such as that about raw material sourcing as well as inventory level at suppliers’ warehouses, could go a long way in eliminating avoidable costs, and significantly enhancing production efficiencies.

“So, we realised that it was important to develop a purpose-built network, which could bring together all suppliers, dealers, and other partners into a common network where they could freely share information. We thought, we will bridge the gap between Web2 to Web3 by building the right stack for the supply chain collaboration,” Sethuraman added.

However, this begs a question as to why two companies cannot arrive at a common ERP platform for easier information flow or better, adopt a third-party service for information transfer? According to Sethuraman, the answers lie in the fact that large organisations work independently, and information security is the most critical thing for these enterprises. No company would jeopardise sensitive information by getting on to a third-party information platform, according to Sethuraman.

ERP-to-ERP communication

The company is working to offer a digital solution to allow companies to share information in an ERP-to-ERP-readable format that allows them to do a lot more in terms of collaboration. “Just think about the possibilities if SAP can talk to an Oracle, and the kind of automation companies can do on top of that,” Sethuraman explained.

“That is where we decided to build a fundamental digital backbone for enterprises to interconnect, exchange data and build trust over this network,” he said.

With the introduction of this platform, Param Network is leveraging the core principle of blockchain technology – decentralisation of information – to ensure bringing in controlled transparency within a particular transaction.

“We have built a non-crypto proprietary blockchain platform for enterprises and it allows to share data in a highly secured fashion. We use high-end cryptography to ensure end-to-end encryption. As a service provider, even we cannot access any data as it does not come to our cloud and goes directly from one ERP to another. We are a data-blind company,” Sethuraman said.

Param Network aims to solve the pain points of the supply chain by providing each stakeholder with the desired outsourced-manufacturing visibility. “Today’s ERPs cannot talk to one another and that is where we intend to bring inventory, production, and despatch visibility – which are more critical today than ever before for the automotive industry to develop more resilience in the system,” he added.

Reducing adoption friction

The company is offering its solutions to big corporations within the e-commerce space and automotive industries, wherein Bosch is one of its key clients for whom it is providing transportation-order management services for creating visibility and generating real-time invoices through smart contracts. Param Network claims that the invoice can be generated within a few seconds of the order getting delivered, therefore, significantly reducing the invoice cycle by approximately 100 days.

“We are cutting down on precious time by giving a trustworthy digital interface. It is one of the use cases on our platform,” said Sethuraman. “Right now, we have a product-market fit and we have a consistent revenue stream over the last one-and-a-half years. We are aggressively growing in India, and have started putting our foot in the US for expanding in the North America region. We are warming up the market and we expect 2023 to bring good sales for our services,” he added.

At present, Param Network is focusing on the automotive supplier ecosystem and gradually eyeing OEMs. “We are mostly working on the supplier side, and are also reducing the friction for adoption by offering the entire solution stack free, in turn, for their suppliers, who could use either an electronic data interchange (EDI) or application programming interfaces (APIs) to use the services.”

“We have converted the platform into a low-code tool and therefore, any supply chain workflow can be built using our drag-and-drop UI. While other solutions aim automation within the organisation, we go beyond,” Sethuraman signed off on a pragmatic note.