Schaeffler’s new software tech centre in Pune to strengthen its e-mobility portfolio

Global supplier Schaeffler, which is expanding its software and electronics expertise, has inaugurated a new centre of competence in software development in Pune.

The facility, in which Schaeffler is investing 10 million euros (Rs 84 crore), will develop electronics and software for the company’s automotive components and systems, especially for e-mobility and chassis applications. It will also play a key role as a strategically important part of the company’s global R&DF network.

The newly formed entity – Schaeffler Technology Solutions India – is a wholly owned subsidiary of the Schaeffler Group and will employ 200 engineers in India by end of 2022 and will be part of Schaeffler’s E-Mobility business division. Schaeffler plans to ramp up the development team in India during the next years, making the country a main location and competence centre for software and electronics development.

Uwe Wagner, Chief Technology Officer at Schaeffler AG, said, “Strengthening competencies in mechatronics, electronics, and software plays a decisive role in Schaeffler’s company strategy Roadmap 2025. In this way, we will actively shape the transformation toward sustainable and electrified mobility. As part of the Schaeffler global R&D network, Schaeffler Technology Solutions India will play a key role here. Together, we are very well equipped to continue our successful journey to pioneer motion.”

“Electrified powertrains have been part of Schaeffler’s core business since 2018 and we have become a leading systems supplier in electromobility in recent years. To further strengthen and expand this position, we will rely on a global R&D network for software and electronics development in the future. Our newly formed entity Schaeffler Technology Solutions India in Pune will become a main location in this network,” said Dr. Jochen Schröder, head of the E-Mobility business division of Schaeffler.

Focus on software for e-mobility projects

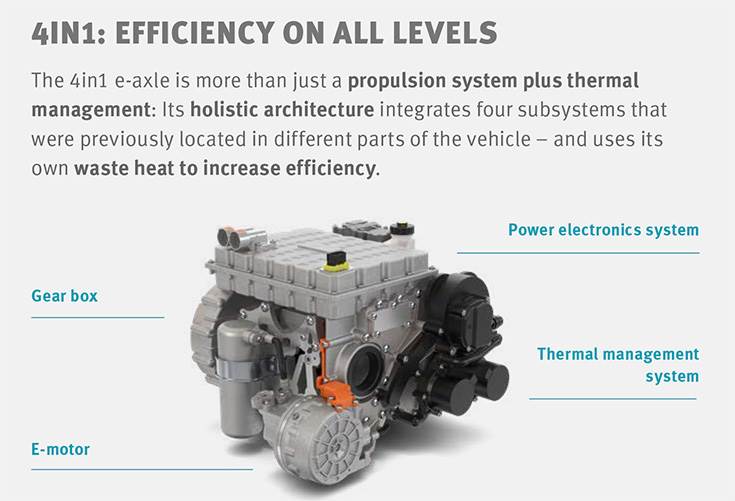

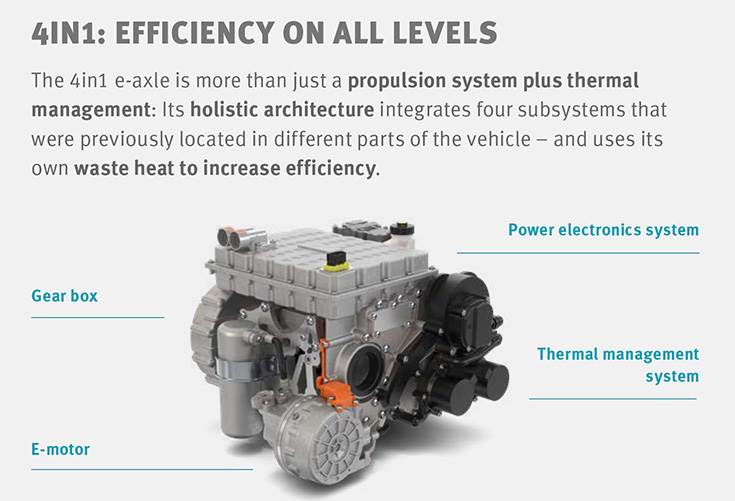

Schaeffler already offers a very broad range of solutions for electric drives and is aiming for major growth in this area. The company develops everything from individual electromobility components to highly complex systems such as a 4in1 electric that integrates electric motor, power electronics, transmission, and thermal management into one comprehensive system.

The 4in1 e-axle is a highly integrated and compact complete system for the powertrain.

This strategy of developing both individual components and complete systems for electric powertrains is paying off for Schaeffler – both technically and commercially. During the first nine months in 2022, the e-mobility business at Schaeffler totaled an order intake of 4.7 billion euros (Rs 39,696 crore) relating to the E-Mobility business division.

The engineers at the new technology centre in Pune will be contributing to this business in the areas of software development, electronics, mechatronics, and validation which are key to seamlessly blend electrical and mechanical components for overall system reliability and efficiency.

Yogesh Patwardhan, Director, Schaeffler Technology Solutions India, said, “In the last few years, we have witnessed fast paced change in technology scape driven by consumer preferences. Schaeffler group is committed to enable the transition towards sustainable mobility by harmonising our manufacturing competency with digitalisation, electric and electronics competencies. As a result, we leverage local strengths that the world has to offer and India has long established itself with its vast engineering talent availability. Schaeffler has a strong base in India already and this center was a natural extension of our commitment to expand our local footprint.”

Schaeffler develops and manufactures a diverse mix of efficient and sustainable drive solutions for a wide range of applications – everything from bicycles to 40-ton trucks. The activities in this area include semi- and fully electrified powertrains, fuel cell systems, and the development of efficient internal combustion engines. It is engaged not just with CO2-efficient powertrains but also with new chassis applications, including technologies that enable highly automated driving.

The new development centre in India will contribute in multiple projects focusing on a range of complex functional safety topics from quality management to ASIL D applications and cybersecurity, leveraging AUTOSAR platform and architecture.