Suzuki Motor Corporation has signed a joint development agreement with Canada-based Inmotive Inc for the development of a two-speed EV transmission for a future Suzuki electric vehicle.

Inmotive was founded in 2010 in Toronto, Canada. They developed the Ingear two-speed transmission, a lightweight, compact, and efficient technology to enhance the performance of EV powertrain units. Inmotive aims to accelerate the global evolution to affordable zero-emission mobility and play an important role in mitigating climate change.

With this joint development agreement for the two-speed EV transmission, Suzuki believes that it has the possibility of extending EV range through efficient use of motor torque while also lowering costs due to using a smaller electric powertrain unit and improving driving performance.

What is Ingear?

Inmotive Inc has invented Ingear, an ultra-efficient multi-speed powertrain technology for a wide range of applications. The Ingear extends EV range at very low additional cost and weight, while providing continuous torque during smooth shifts. The company says Ingear’s “highly reliable design also increases torque, acceleration, gradeability and top speed.”

The adoption rate of EVs has been hampered by range anxiety, performance issues and high cost. Inmotive states that it addresses these problems with its two-speed Ingear transmission, which provides double-digit performance improvements while allowing for cost reduction by downsizing batteries and other components. Inmotive believes Ingear will accelerate the adoption of EVs globally because it reduces both capital and operating costs of EV ownership.

How Ingear works

Most EV motors are single-speed. Typically, there are two helical reduction gears between the motor and the wheels. The motor turns about nine times for each revolution of the wheels.

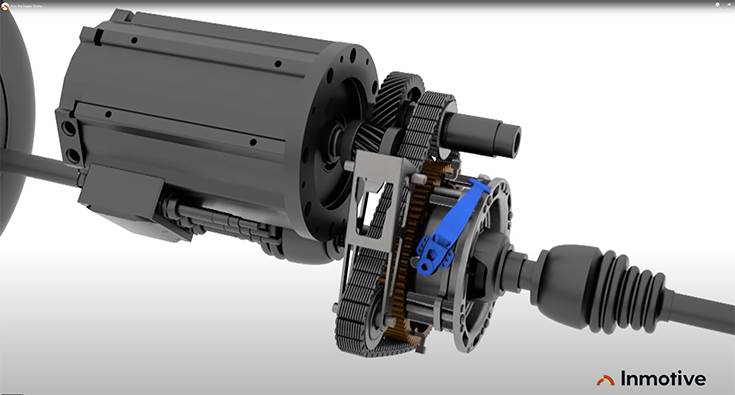

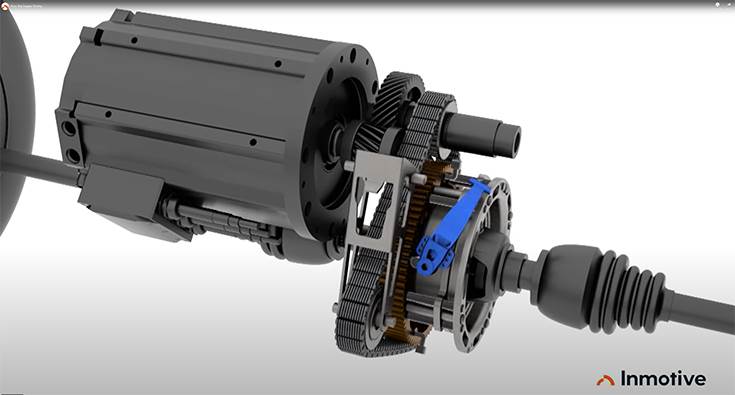

Ingear replaces the second reduction gear with a continuous chain drive and an innovative morphing sprocket that resizes during a shift. The entire shift happens during a single revolution of the wheels.

To shift, an actuator directs outer gear segments in or out of the chain path, while the motor speed is carefully adjusted so that shifts are barely perceptible and can be completed in as little as 19 milliseconds.

Combined with a chain and chain-tensioner, Ingear provides for 2:1 or similar gearing ratios. The extremely efficient chain is always kept in line with the morphing sprocket.

Low-gear is used to move the car from a standing start to half of highway speed. High-gear is used for higher-speed driving. By enabling the electric motor to operate more efficiently, more of the battery’s power is used to move the car, and less is wasted as motor and transmission heat. Less waste means more range from each charge.

ALSO READ: This EV gear-changer could be a game-changer