The transition to electric mobility, particularly in the two- and three-wheeler segments, is gaining traction in India. However, charging these electric vehicles at home or work remains risky and difficult, if not impossible, due to a lack of dedicated parking or charging time.

Furthermore, many owners live in multi-storey buildings with no dedicated parking. As a result, in the short term, the battery swapping model provides an alternative option for charging electric two- and three-wheelers and accelerating EV adoption.

The International Council on Clean Transportation (ICCT) recently investigated the landscape of battery-swapping networks for electric two-wheelers in collaboration with NITI Aayog. It is a low-cost and quick solution for these eco-friendly vehicles in India. Firstly, manufacturers can sell the vehicle without a battery, which reduces the upfront cost of the electric two- and three-wheelers by 30 percent. Secondly, battery swapping will allow urban riders to stop at a station, drop off their drained batteries, and pick up fully charged ones in seconds, improving their time efficiency.

Battery swapping is part of the larger framework of Battery as a Service (BaaS) business models, which involve users purchasing an EV without the battery and paying a regular subscription fee (daily, weekly, monthly) to battery service operators (BSOs) for battery services over the vehicle’s lifetime. Under the BaaS model, customers benefit from guaranteed access to optimised, high-performance batteries rather than owning a battery that loses performance over time.

Because BSOs own the batteries, they face significant challenges in managing insurance costs, battery operational life, and repurposing batteries for second-life applications. An intelligent and adaptive battery management system (BMS) is the key to solving this problem because it can help in not only tracking battery parameters but also accurately predicting cell/module/pack level issues in the real world and taking proactive actions to ensure battery performance, safety, and remaining useful life (RUL). Furthermore, monitoring each battery to ensure the safe and effective operation is critical for predicting BSO business sustainability.

Why predicting the RUL of the battery is essential

If the allotted batteries degrade, the owner of an electric two-wheeler who uses a BSO’s service may experience inconsistent driving range. Batteries degrade even faster if the previous user rides or drives aggressively, with rapid acceleration and braking. Furthermore, battery life is reduced by frequent total charges and deep discharge, especially at higher temperatures. Most likely, the batteries will be fast-charged at BSO’s charging stations several times daily.

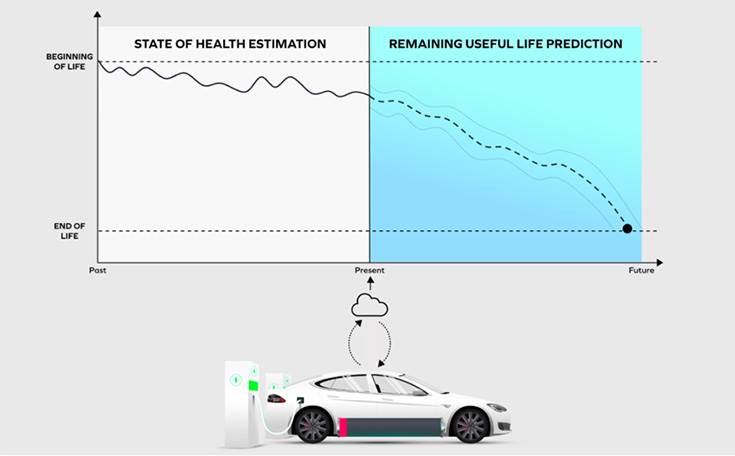

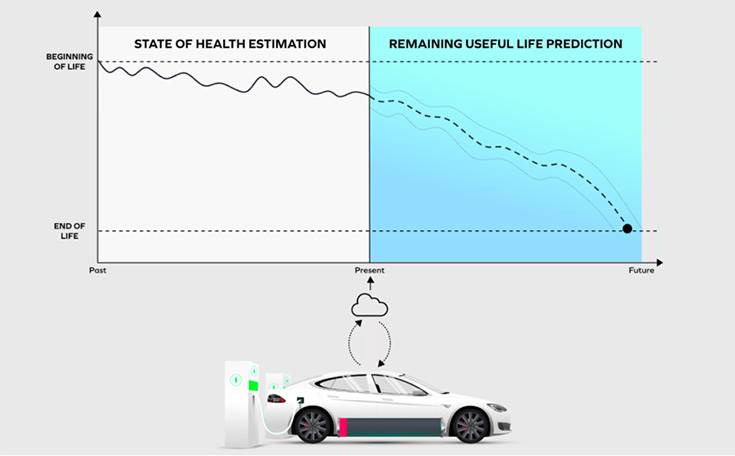

A battery’s Remaining Useful Life (RUL) is critical for any BSO operator’s business because batteries are expensive, and replacing batteries with new ones regularly will not be sustainable for BSOs and other EV ecosystem players such as financiers, insurers, and even end users. As a result, various methods and techniques have been developed to predict battery RUL and improve the accuracy of State of Charge (SoC) estimation. RUL is defined as the time the battery’s performance reaches the failure threshold (e.g., 80% for EV) for the first time, also known as the first arrival time. Figure 1 depicts the significance of predicting RUL in determining battery life.

Figure 1. The remaining functional life prediction improves battery longevity and durability. (Source: Eatron Technologies)

How AI is revolutionising the BMS

BMS powered by artificial intelligence (AI) can provide more accurate RUL indications. The AI network is based on experience and does not rely on the electrochemical principles inside the battery. AI algorithms can also learn and recognize more complex patterns in battery usage data and forecast the RUL of a battery. As more data is analysed, the AI learns, predictions become more accurate, and the benefits are automatically incorporated into decision-making.

Another advantage of RUL prediction is that it will allow the vehicle manufacturer to take a corrective/preventive decision in terms of limiting the power and SOC to avoid battery abuse and faster degradation. This kind of adaptive BMS which learns from filed data and issue over-the-air calibration updates that maximise customer benefits, such as fast charging and range while maintaining the battery’s warranty and durability.

Combining AI with a cloud connection will give BMS a much more critical role as a tool for maximizing electric two- and three-wheeler attributes and providing warranty management data. Managing and validating the RUL will also add significant value to BSO’s battery disposal. BMS can collect real-time data throughout the vehicle’s life, rather than just during the design stage, making it more than just standard AI technology. Vehicle manufacturers can add new features that provide owners with additional information, such as the RUL of an EV’s battery, which is valuable data for resale buyers.

BMS prognostics

Battery failures and fires caused by thermal runaways are becoming more common, resulting in high warranty/recall costs, a negative impact on consumer sentiment, and a slowing of EV adoption. Such fires also affect the brand value of EV manufacturers. BMS Predictive Diagnostics powered by AI aids in overcoming this challenge. Measurement noise typically drowns out early warning signs of trouble in battery cells. AI assists in determining whether we have detected an early warning sign of trouble or if it is simply measurement noise. AI-based BMS prognostics provide immediate benefits, such as eliminating the need to over-specify the battery to ensure durability, resulting in lower warranty costs.

Furthermore, the BMS can monitor and control how close to full charge and discharge the battery can get. This will extend the battery’s life. Moreover, warranty claims can be reduced by calibrating the BMS so that the battery is never charged to total capacity, never approaching deep discharge, even if the vehicle is only a few miles from a charging station. Manufacturers can also update BMS calibrations regularly to provide more range and faster charging while reducing the risk of being stranded on the side of the road with a disabled vehicle.

Looking at the benefits of continuous battery monitoring, BMS development will take centre stage in the coming days, providing the most critical battery prognostics and RUL data for BSOs. AI-powered BMS could also detect cell-related issues months before a failure occurs rather than seconds before, as is currently the case. Once electric two and three-wheelers become ubiquitous, many millions of batteries will be in use, and extending their life by a few months or years would significantly reduce CO2 emissions.

In a nutshell, advanced AI-based adaptive BMS is the most economical and sustainable way forward to go net zero.

Lead image source: Eatron Technologies