Japanese automotive multinational Toyota has revealed how adopting Zortrax 3D printing has helped optimize its vehicle assembly operations.

At its two Polish facilities in Walbrzych and Jelcz-Laskowice, Toyota has switched from CNC machining assembly jigs and fixtures to producing them using Zortrax M300 Plus systems on-demand. In doing so, the automotive stalwart has managed to reduce the costs and lead times behind manufacturing essential tools and spares, in a way that has optimized its production line performance.

“We do not have to store spare parts, because we can 3D print them on demand. We can start a 3D printing process whenever such a need occurs,” explains Łukasz Kondek, the engineer responsible for 3D printing at Toyota. “We don’t have to wait until our tooling department (or an outsourcer) has the capacity to take care of our orders. 3D printing shortens waiting time for needed tooling from weeks to days, or sometimes even hours.”

“We can optimize our projects freely since 3D printers materialize nearly all geometries imaginable.”

M-Series 3D printing at Zortrax

While Zortrax expanded into the resin 3D printing space in 2018 with the launch of the original Inkspire system, it’s best known as a manufacturer of Fused Filament Fabrication (FFF) machines. On this side of its portfolio, the firm offers its Endureal, M200 Plus, M300 Dual, and M300 Plus 3D printers, each of which operates using its proprietary Layer Plastic Deposition Plus (LPD) extrusion technology.

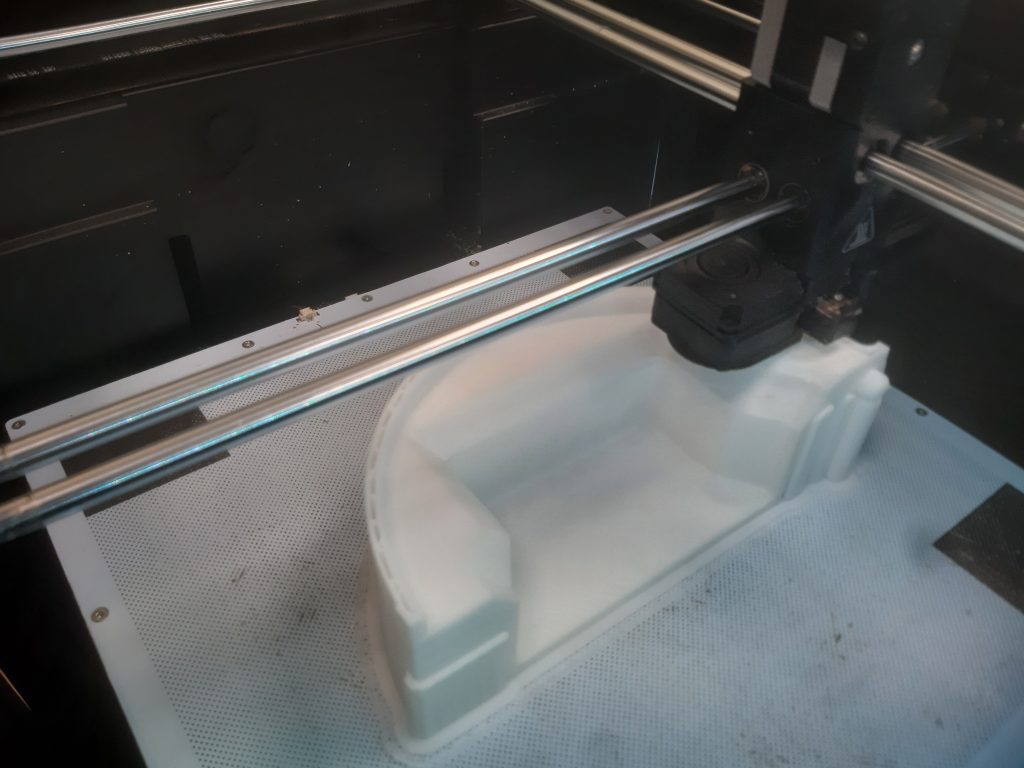

Having installed the latter, Toyota has adopted the largest of the three, which thanks to its 300 x 300 x 300 mm build volume, is capable of creating huge parts in single prints. In practice, this means users don’t have to break large-format models down into separate pieces for assembly, something that can necessitate the integration of joints – weak spots that often impact long-term durability.

The system’s packaged farm management software also makes it particularly well-suited to deployment at scale, while its support for third-party filaments has lent it wide-ranging applications, including everything from solar energy product prototyping, to the manufacture of unique Cyberpunk-inspired cosplay outfits.

To further improve the capabilities of its offering, Zortrax also continues to introduce materials and upgrades for its machines. Last year, the company rolled out a new ‘space-grade’ Z-PEEK 3D printing filament. Since then, Zortrax has launched its Full Metal Packages, which make metal 3D printing possible on the Endureal.

Toyota’s Polish 3D printing exploits

Much of the work at Toyota’s factories in Poland revolves around mounting engines into the cars it assembles and then sells in Europe. Housed inside the facilities, in which over 3,000 employees now work on both Toyota petrol and hybrid vehicles, are dedicated 3D printing labs that have installed more than 100,000 zł ($23,000) worth of Zortrax equipment.

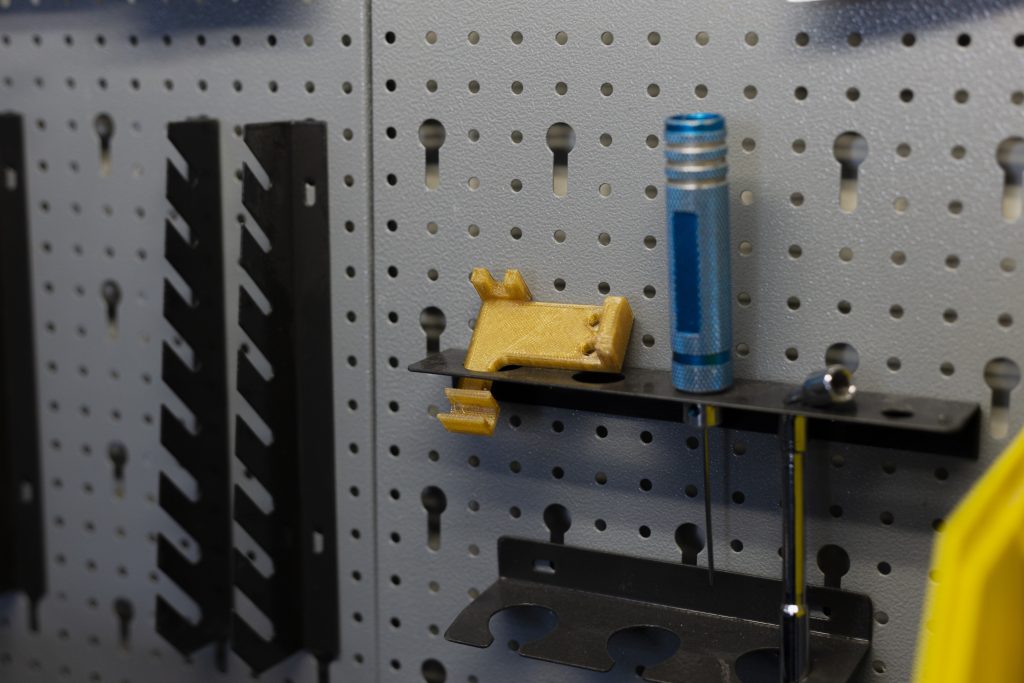

For years, engineers at Toyota’s Polish facility have deployed the Zortrax M300 Plus in jig, tooling, and spare part production applications. The parts currently 3D printed at the firm’s plant fall into four categories: positioning jigs, assembly jigs, assembly tools, and covers. Once printed, these are often combined with other components created using subtractive technologies to form integrated assemblies.

For instance, the gauges used in some Toyota vehicles feature a 3D printed body. However, as the pins on these instruments are continually in contact with a metal surface, they’re now CNC machined, in a way that improves their durability.

Additionally, Toyota’s assembly line jigs were previously manufactured by a separate department equipped with CNC machines. As a result, the company’s engineers had to design these tools around the constraints imposed on them by traditional manufacturing technologies. Since switching to 3D printing, however, Toyota has been able to slash its lead times and minimize assembly line disruption.

“One of the key benefits of implementing Zortrax 3D printers in manufacturing & industry is their tried and true, stable construction and ease of maintenance,” adds Michał Siemaszko, Head of R&D at Zortrax. “That means that global manufacturers like Toyota can rely on them while printing equipment critical to keeping the assembly line running.”

“Reliability is essential, as even short delays can generate losses that far exceed the value of the printers themselves. Therefore, what we offer large industrial customers is assurance.”

AM in automotive jigs, tools and fixtures

Toyota is far from the only car manufacturer that’s 3D printing jigs, fixtures, and tooling, and the technology continues to gain ground in automotive. In 2021, it was announced that Audi now uses more EOS-3D printed tooling at its Metal 3D Printing Centre in Ingolstadt, where models such as the A4 saloon are assembled.

That year, it was also revealed that Skoda deploys 3D printing in automotive spare part production, prototyping, and tooling applications. As part of plans to double down on digitization at its manufacturing facilities, the company has set up several print farms featuring systems developed by popular printing brands like Prusa.

Elsewhere, using ExOne binder jetting, FreeFORM Technologies has 3D printed tooling for the automotive industry as well. In the past, the firm has 3D printed a complex end-of-arm tooling component for Allegheny Electric Service, which in turn, attached it to a six-axis FANUC robot as part of a part inspection system.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the automotive production process at Toyota. Photo via Zortrax.