Continental targets sustainability in tyres with recycled rubber, rice husk and plastic bottles

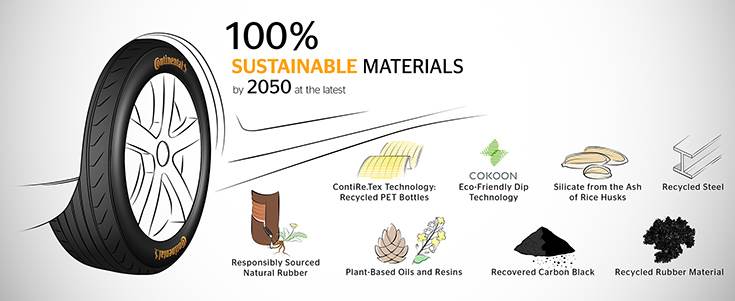

Technology and tyre company Continental is upping the sustainability quotient in its tyres. For some time now, the material experts and tyre engineers at Continental, which has targeted all tyres to be made of sustainable materials by 2050 at the latest, have been engaged in plenty of R&D activity on this front.

While there is still a long way to go until then, step by step, it is already becoming apparent which raw materials will find their way into tyre construction in the future. These include waste products from agriculture – such as the ash from rice husks – rubber from dandelions, recycled rubber or PET bottles.

laus Petschick, Head of Sustainability at Continental Tires, says: “Continental is on the road toward becoming the most progressive manufacturer in the tyre industry in terms of sustainability. We aim to use 100% sustainable materials in our tyre products by 2050 at the latest. Our innovative power enables us to break new and even more sustainable ground. This encompasses everything from the origin and sourcing of our materials through to the reuse and recycling of our tyres.”

Already today, around 15 to 20% renewable or recycled materials are used in a standard passenger car tyre from Continental. To further increase the proportion of sustainable materials and conserve valuable resources, the company continuously analyses and reviews all raw materials used in tyre production. Passenger car tyres from Continental consist of as many as a hundred different raw materials and depending on the application, season and environment, they have to fulfill specific requirements.

Recycled rubber, rice husks and PET bottles: sustainable materials in tyre production.

Recycled rubber, rice husks and PET bottles: sustainable materials in tyre production.

Natural rubber still essential

Natural rubber is essential for ensuring outstanding tyre performance. This natural product accounts for between 10 and 40% of the entire weight of modern high-performance tyres. Its special properties include the high level of strength and durability, which are caused by the strain-induced crystallization of the rubber. The tyre industry is the biggest consumer of global rubber production, accounting for more than 70 percent.

However, Continental considers natural rubber a sustainable material only if it is sourced responsibly. Therefore, it employs an integrated approach aimed at making the complex and fragmented supply chains for natural rubber more sustainable. This includes using cutting-edge digital technology, local involvement and close collaboration with capable partners with the goal of improving transparency and traceability along the entire value chain.

Meanwhile, with its Taraxagum project, Continental is pursuing an innovative approach to ensure that it can become less dependent on natural rubber grown primarily in southeast Asia. The tire manufacturer is working alongside partners on industrializing the extraction of natural rubber from specially cultivated dandelion plants.

Sustainable plant-based fillers

In addition to rubber, fillers such as silica are essential to tyre assembly. Silica, for example, helps to optimise characteristics such as grip, rolling resistance and tyre life. In the future, rice husks will be used as the source material for sustainably produced silica. Rice husks are a waste product of rice production and cannot be used as food or animal feed. Silica derived from the ash of rice husks is more energy-efficient when used in manufacturing than that obtained from conventional materials such as quartz sand.

Plant-based oils – such as rapeseed oil and resins based on residual materials from the paper and wood industries – already offer an alternative to crude-oil-based fillers in Continental’s tyres. Only oils that meet technical quality standards and are not suitable for consumption are used. Oils and resins allow for flexibility in terms of tire compounds and so improve the material’s grip.

Expanding the circular economy

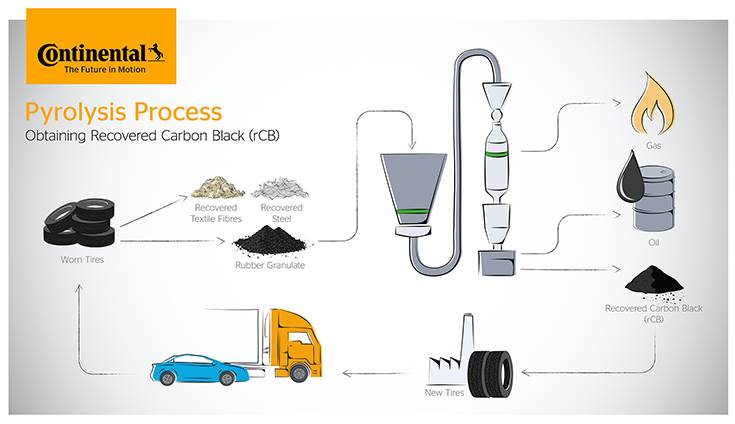

Continental is aiming for fully circular operations in its tyre production by 2050. In addition to the use of renewable materials, the company is working systematically on using recycled raw materials in tyre production. This is intended to ensure that carbon black – another crucial filler in rubber compounds – can be obtained on a large scale in the future.

Continental has recently signed a development agreement with Pyrum Innovations with a view to further optimising the recycling of materials from old tires. To do this, Pyrum breaks the old tyres down into their constituent parts in an industrial furnace using a special pyrolysis process. In this way, valuable raw materials contained in end-of-life tyres can be extracted and recycled.

Continental has recently signed a development agreement with Pyrum Innovations with a view to further optimising the recycling of materials from old tires. To do this, Pyrum breaks the old tyres down into their constituent parts in an industrial furnace using a special pyrolysis process. In this way, valuable raw materials contained in end-of-life tyres can be extracted and recycled.

In addition to pyrolysis, Continental is also making use of mechanical processing of end-of-life tyres. Rubber, steel and textile cord in particular are separated, in a highly sophisticated process, from one another. The rubber is then prepared for re-use as part of new rubber compounds.

Continental is working to advance innovative technologies and sustainable products and services throughout its entire value chain, from sourcing sustainable materials to recycling end-of-life tyres.

Continental is working to advance innovative technologies and sustainable products and services throughout its entire value chain, from sourcing sustainable materials to recycling end-of-life tyres.

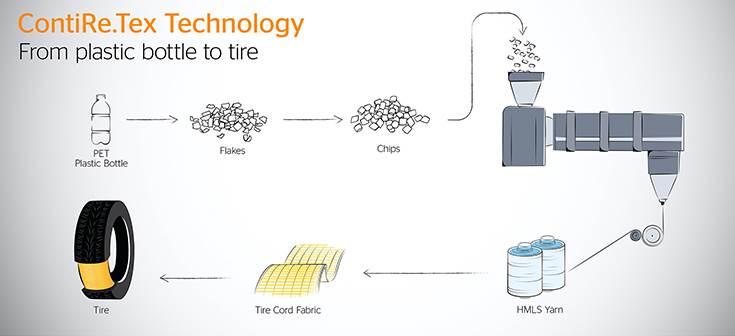

Recycled plastic bottles in tyre casing

Recycled raw materials are going to play a big role in making tyres more sustainable. “We use recycled materials whenever possible. Comparable quality and material properties to conventional raw materials are crucial for us,” says Petschick.

For example, Continental is working with partners to obtain high-quality polyester yarn for its tyres from recycled PET bottles. PET bottles often end up in incinerators or landfills otherwise. With its ContiRe. Tex technology, the tyre manufacturer has developed a more energy-efficient and eco-friendly alternative that allows it to reuse between nine and fifteen plastic bottles for each tire, depending on the tire size. The recycled PET has already replaced conventional polyester in the structures of some tire casing. The PET bottles used are sourced exclusively from regions where there is no closed recycling loop.

ALSO READ:

Tech Talk: Sustainable tyres pass a new milestone

Apollo Tyres develops concept tyre with 75% sustainable materials