Honda has developed and showcased the new capabilities of the latest generation of its prototype Honda Autonomous Work Vehicle (AWV) to improve construction industry and worksite efficiencies at CONEXPO-CON/AGG 2023 in Las Vegas, last week.

“As we continue to advance the Honda AWV platform, we want to meet with potential business partners and companies at CONEXPO that are interested in field testing the vehicle at their worksite,” said Jason VanBuren, systems engineering manager at American Honda Motor Co. “We believe the Honda AWV can be a valuable solution to supporting construction teams while also enhancing worksite efficiencies and safety. Leveraging Honda’s decades of experience developing reliable, safe and clean mobility technology, we aim to address issues such as labor shortages and improved environmental performance.”

The fully programmable all-electric Honda AWV third-generation prototype leverages the company’s emerging advanced autonomous technology to create a rugged off-road work vehicle that is designed to support construction-related activities and enhance workforce productivity. With the ability to operate autonomously – or manually via remote control – the Honda AWV could provide a wide range of services to industries that need autonomous operation or delivery solutions, especially where workforce constraints make other solutions impractical. The company is also exploring the development of attachments and tools that could make the vehicle a suitable platform for many work environments.

Honda states that it has successfully field tested the second-generation Honda AWV at a large-scale solar construction site in the Southwest U.S. Based on real-world testing, the company is now introducing the third-generation Honda AWV which features a number of enhancements.

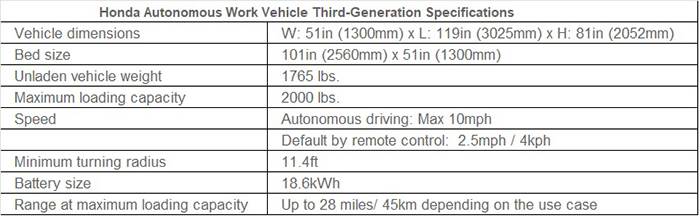

Key features of the third-generation Honda AWV include:

– Increased bed size to 2 pallets and greater loading capacity of 2000 pounds.

– Improved navigation in locations where GNSS (global navigation satellite. system) service is weak or unavailable through the use of LiDAR sensors.

– Simplified tablet-based programming interface and cloud connectivity.

– Higher speed in autonomous mode – up to 10 miles per hour/ 16kph.

– Increased battery size and longer operating time of up to 10 hours.

– Enhanced avoidance function for vehicles stopped on road.

– Lower bed for easier loading and improved ergonomics.

The Honda AWV employs a suite of sensors to operate autonomously, using GPS for location, radar and lidar for obstacle detection and cameras for remote monitoring. Previous field tests have also successfully verified that multiple Honda AWVs can transport and deliver construction materials and supplies at precise points along a pre-set route. The vehicle leverages Honda’s extensive portfolio of mobility technologies, using common components from its automobiles and other products.

Honda, which aims to commercialise the AWV, is looking for partners to participate in field testing, as well as to improve functions and enhance services, especially in the areas of product distribution, product support / aftermarket sales, and software and attachment development.