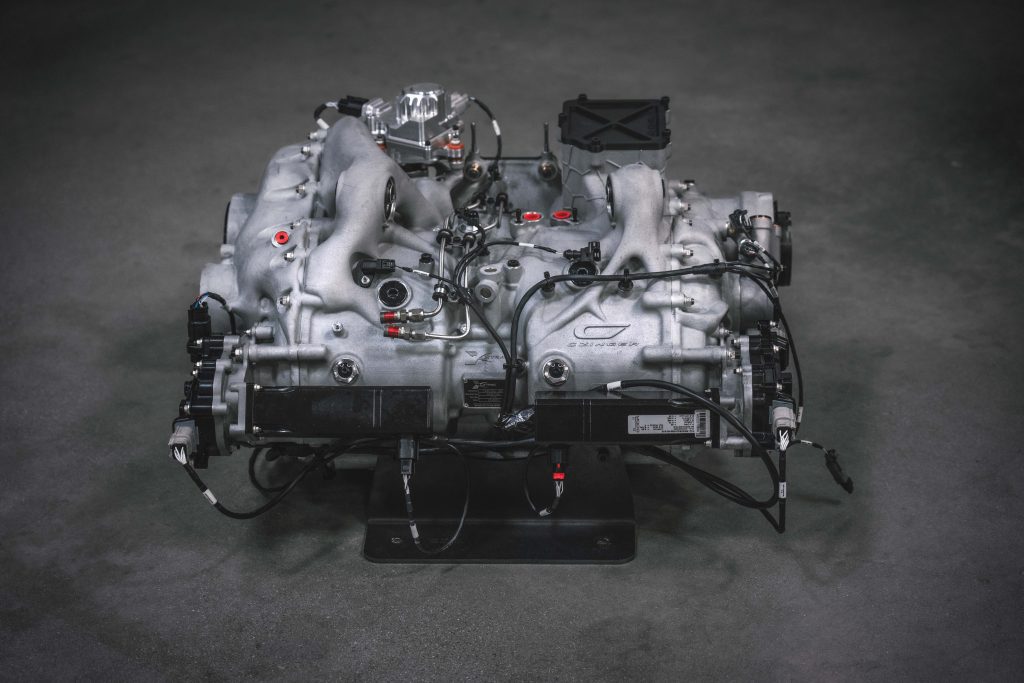

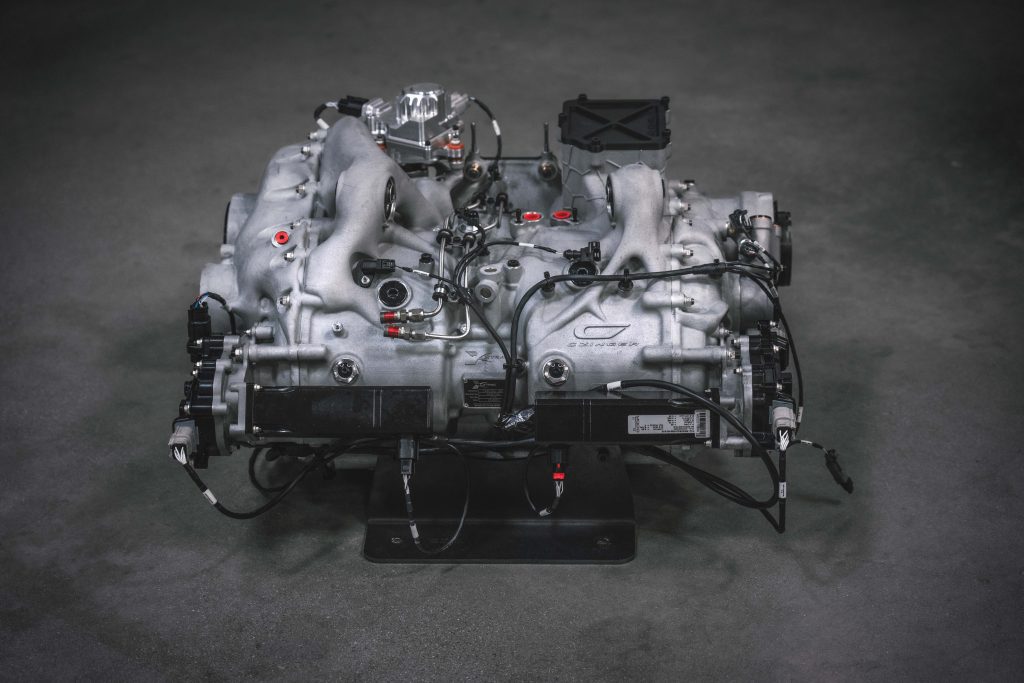

California based motor company Czinger Vehicles is working with Motorsport & High Performance Automotive (HPA) gearbox production specialists Xtrac, to produce a topology-optimized and additively manufactured gearbox.

The 3D printed automated 7-speed semi-sequential gearbox, billed as an industry first, will be incorporated into Czinger’s 21C Hypercar. The gearbox offers sub-100ms shifts, the highest torque transmitted per mass of gearcase for any road-legal vehicle, dual barrel gear actuation, and a 48V- electrically actuated twin barrel system which is said to make it the fastest single clutch synchromesh gearbox in existence.

A unique printing process is used alongside proprietary aluminum to produce the gearbox. It is claimed that this process has facilitated significant weight savings, strong structural performance, high production quality, and efficient printing times. Moreover, this AM process has eliminated the need for tooling, reducing development times and allowing for real-time design improvements to be made.

“We are proud to team Czinger’s world-class engineers with those at Xtrac,” commented Czinger Co-Founder and SVP Operations Lukas Czinger. “Together, we have developed an incredible industry first, gearbox that is truly at the pinnacle of performance. We can’t wait to shatter more track records as we utilize this system in 21C”.

Xtrac CEO Adrian Moore called the project “groundbreaking”, with Xtrac “pleased to be at the forefront of cutting-edge gearbox manufacturing by creating these 3D printed casings”. “It has been extremely interesting and very stimulating for our engineers working closely together to bring this cutting-edge innovation to life,” continued Moore.

The 21C Hypercar

The gearbox will be introduced into Czinger’s 21C Hypercar, a $2 million vehicle which leverages AM technology for a number of its components.

To produce the car, Czinger utilized sister firm Divergent Technologies’ Divergent Adaptive Production System (DAPS). DAPS is essentially an automated hardware-software assembly platform which combines 3D printing and generative design to offer an end-to-end alternative to the traditional automotive production processes. Capable of computational engineering, printing, and assembling automotive builds with minimal human intervention, DAPS enables the production of multiple different car models on the same machine, whilst allowing for rapid design iteration.

During Goodwood 2022, 3D Printing Industry spoke to Kevin Czinger, the founder of Czinger vehicles, who revealed that the 1,250 horsepower hypercar’s chassis and suspension system is almost completely 3D printed. “If you look at the chassis itself, almost all the frame structure is designed, printed and assembled using DAPS. As is the entire suspension system, except things like shock absorbers, that’s all 3D printed. I’d say the induction and exhaust elements of the engine, they’re all 3D printed as well”, highlighted Czinger.

The 21C’s V8 engine is also boosted by electric motors held in place by printed ‘MotorNodes’. Furthermore, DAPS-printed ‘BrakeNodes’ allows calipers to be integrated into its brake uprights, yielding a 40 to 50% part count reduction and 40% weight savings.

AM and the automotive industry

Czinger is not the only automotive company who have utilized AM technology in the production of key components for their vehicles. In 2021, Rodin Cars, a New Zealand-based automotive manufacturer, announced that its ‘FZERO’ hypercare was set to incorporate a 3D printed gearbox. Rodin partnered with US 3D printer manufacturer 3D Systems’ Application Innovation Group (AIG) to produce the gearbox, leveraging a DMP Factory 500 system.

At the time, this gearbox was believed to be the first of its kind, offering a unique eight-speed sequential transmission system. 3D Systems claimed that, given its complex internal galleries, thin-wall bearing structure, and overall weight of just 68 kilograms, the gearbox couldn’t have been manufactured in any other way.

Elsewhere, in 2022 British sports car manufacturer Aston Martin introduced a new roadster featuring a unique 3D printed rear assembly produced by Divergent Technologies and its DAPS system. In the rear of its DBR22 model, Aston Martin integrated a support structure composed of multiple 3D printed aluminum parts bonded together, yielding a significant weight saving. “Divergent is proud to be working with Aston Martin Lagonda and other major global OEMs to transform the future of automotive design and engineering”, commented Kevin Czinger.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Czinger and Xtrac’s 3D printed gearbox. Photo via Shamin Abas.