eVTOL developer Joby Aviation announced it has signed a long-term supply agreement with Toyota Motor Corporation to support a mutual goal of reaching mass production of electric passenger aircraft in the US. The agreement extends upon an existing partnership between the two companies.

Joby Aviation, Inc. ($JOBY) is a California-based company developing electric, vertical takeoff and landing (eVTOL) aircraft with the goal of operating a fast, quiet passenger transportation service to cities around the globe.

The start-up caught our attention back in 2018 when it announced $100 million in funding, led by some big names in tech, including the venture arms of Intel, JetBlue, and Toyota. In 2020, Toyota led Joby’s Series C funding round, investing $394 million of the $590M pledged.

As part of the investment, Toyota acquired a minority stake in the eVTOL company as part of a collaboration in which it said it would share its expertise in manufacturing, quality, and cost controls to support Joby’s development and production of electric aircraft.

Today, Toyota and Joby have extended their yearslong relationship with a new supply agreement to further the latter’s progress of scaling eVTOL production.

Toyota to supply key eVTOL parts to Joby Aviation

As Joby Aviation’s largest external shareholder, Toyota is now expanding its involvement in eVTOL development and production. Through previously announced collaborations, Toyota has already shared production and assembly advice, including insight into the design of Joby’s pilot production line in Marina, California.

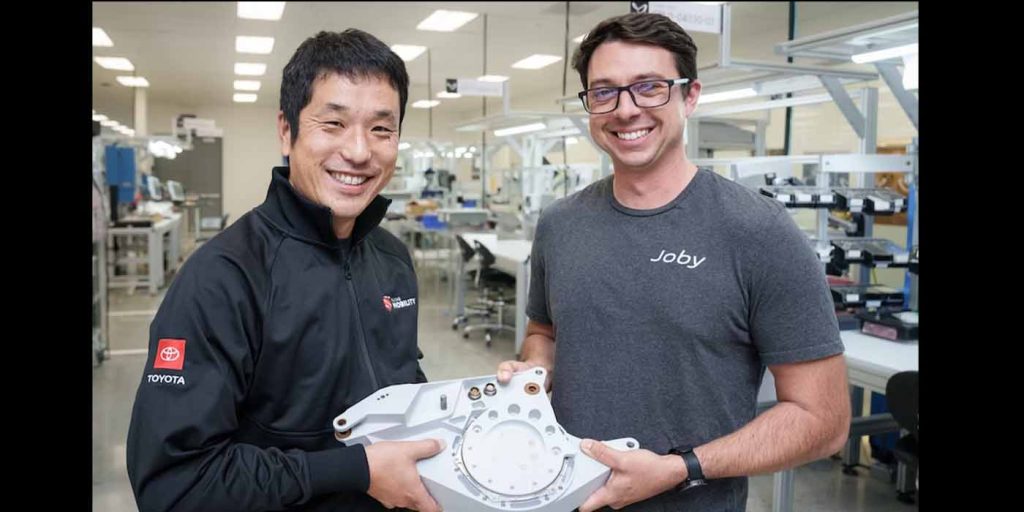

Under a new long-term agreement, Toyota will supply Joby with key powertrain and actuation components vital to the production of its eVTOLs. Toyota Motor Corporation Connected Company president Keiji Yamamoto spoke to the latest agreement with Joby Aviation:

We are very pleased to have reached this milestone with our key partner. Our mutual goal is mass production of eVTOL and helping Joby apply the best practices of the Toyota Production System in meeting high quality, reliability, safety, and strict cost standards. We are excited about the potential for further collaboration as we seek to realize Mobility for All with a seamlessly integrated air-to-ground mobility network.

The key eVTOL components will be designed by Joby and manufactured by Toyota. Those parts will then be shipped to Joby’s powertrain and electronics facility in San Carlos, California, for final assembly before shipping to the aviation company’s pilot production line in Marina for eVTOL integration.

The pilot line was designed by both companies to validate scalable tooling and assembly process at low volumes before attempting mass eVTOL production. With Toyota’s help, Joby is confident it can deliver a “best-in-class” eVTOL at scale.

Looking ahead, the eVTOL technology could eventually transport passengers in Toyota’s native Japan, as Joby is already working with the automaker’s subsidiary Aero Asahi on a taxi shuttle service overseas. Joby relayed that it has already applied to the Japan Civil Aviation Bureau (JCAB) to validate its aircraft type certification and plans to obtain Federal Aviation Administration (FAA) certification as well.

FTC: We use income earning auto affiliate links. More.