Bosch wants to bring steer-by-wire systems to the market on a commercial scale by the middle of the decade. Together with Arnold NextG, the supplier of technology and services is taking the next step. The two partners have recently entered into an alliance to pool their development expertise and accelerate the process of readying the solutions for the market.

German start-up Arnold NextG specialises in the development of multi-redundant drive-by-wire systems with all interfaces for autonomous driving in small and very small batch sizes. Based in Pfronstetten-Aichelau, the start-up has employees with over 20 years’ combined experience in street legal drive-by-wire technology, giving the company unique expertise in developing retrofit solutions for all by-wire applications. Experience has shown that, thanks to the redundancy of Arnold NextG technology, the authorities can issue system approvals for driving on public roads more quickly and efficiently. Together, Bosch and Arnold NextG aim to accelerate the development of systems that can be manufactured on a commercial scale.

Steering systems of the future

Steer-by-wire systems are considered the steering systems of the future. As one of the world’s leading suppliers of electric steering systems, Bosch states that it recognised the potential of steer-by-wire systems early on and is systematically driving their development forward.

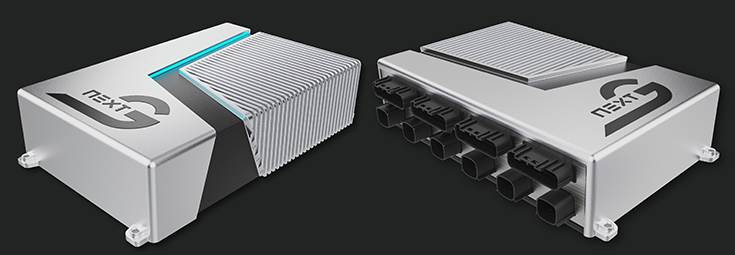

The multi-redundant NX NextMotion central control unit from Arnold NextG provides the necessary road approval up to autonomous driving (Level 5).

The multi-redundant NX NextMotion central control unit from Arnold NextG provides the necessary road approval up to autonomous driving (Level 5).

By-wire systems use electronics to transmit mechanical signals and pulses. They will also be a basic requirement for assisted and automated driving in order to fully tap the capabilities of individual functions. For example, the lane-keeping support system would be able to correct the direction of travel without the driver feeling it in the steering wheel. The vehicle can also avoid an unexpected obstacle without jerking the steering wheel and injuring the driver. With this technology, it may even be possible in the future to steer the wheels individually. This ensures a smaller turning radius and opens the door for new vehicle concepts for local traffic and goods transport in cities

“We’re seeing rapidly rising demand for steer-by-wire systems. This should prove to be an exceptionally large market over the long term – especially, although by no means only, for the age of automated driving. We’re excited to see the momentum this alliance will lend to our work on system optimization,” said Dr. Gerta Marliani, president of Robert Bosch Automotive Steering GmbH.

The aim of the partnership is to accelerate the large-scale production of steer-by-wire solutions. Steer-by-wire applications eliminate the physical connection between a vehicle’s steering wheel and its wheels. This opens up new possibilities for, say, redesigning the vehicle interior: the steering wheel can be lowered or stowed away, giving rise to entirely new cockpit concepts, especially in an age of automated driving. The technology also enables new safety features in vehicle dynamics control. For instance, even small automated steering interventions can stabilise the vehicle without the driver at the wheel even noticing. In addition, the vehicle’s driving feel can be tailored to the requirements of individual vehicle manufacturers.

Pooling by-wire expertise

“The alliance with Arnold NextG provides ideal support and accelerates our product development. We can apply our expertise in large-scale production and, with the Arnold NextG technology installed, we can now carry out tests on public roads more quickly,” said Dr. Stefan Waschul, the member of the Robert Bosch Automotive Steering GmbH management board responsible for development.

Commenting on the new alliance, Kevin Arnold, founder and CEO of Arnold NextG, said: “We’ve seen that the Bosch steer-by-wire system has the best and most natural steering feel in the market. Bosch is one of the world’s leading suppliers of electric steering systems and already offers a strong package of control technology and performance for large-scale applications downstream. That’s why I’m proud, not only to be able to build on one of the best systems, but also to have Bosch – one of the biggest automotive suppliers in the world – at our side.”

He added, “With the Arnold NextG technology, Bosch has a vehicle-agnostic development platform for drive-by-wire retrofit solutions that makes it possible to validate data and requirements for large-scale production projects at an early stage of development. Together, we can further develop this technology for large-scale manufacturing. Access to Bosch technology and the experience of a global corporation in implementing large-scale production projects is crucial for the further development of our systems.