With growing electrification of mobility and transportation systems, battery design and thermal management are increasingly becoming areas of high priority for OEMs and system suppliers which intend to offer top-notch safety in their products.

Multiphysics simulation systems provider COMSOL is tapping into this requirement of the automotive ecosystem, and solving the industry’s challenges of modelling thermal runaway and abuse in batteries, and enabling determination of the right cell arrangement, as well as battery pack designs which can consistently offer reliable operation.

In a virtual masterclass on the subject – Modelling thermal runaway and abuse in batteries – held on June 21, in association with Autocar Professional, COMSOL Applications Engineer Dr Rustam Shekhar explained the core competencies of the COMSOL Multiphysics simulation tool, and how it can be leveraged by domain experts to model and design a battery pack.

In a virtual masterclass on the subject – Modelling thermal runaway and abuse in batteries – held on June 21, in association with Autocar Professional, COMSOL Applications Engineer Dr Rustam Shekhar explained the core competencies of the COMSOL Multiphysics simulation tool, and how it can be leveraged by domain experts to model and design a battery pack.

Dr Shekhar explained that the company’s battery design module can handle various chemistries, and go beyond the typical lithium-ion cell chemistry, and look at sodium-ion and other emerging cell chemistries as EVs undergo a continuous phase of evolution. The modelling of such a battery pack would require the electrochemistry of the cells, with the COMSOL suite allowing analyses.

“The analyses could be performed by conducting time-dependent studies, including target analyses and some impedance plots which help in model comparison with external data, and help measure battery performance. The system allows to assess fundamental equations like Nernst-Planck equation, and kinetics theories pertaining to the electrodes,” Dr Shekhar said.

Nipping thermal runaway

In a tropical country like India where the predominant parts of its geography reel from high temperatures for a major part of the year, many EV OEMs have faced the problem of thermal runaway in the recent past, leading to a spade of fires erupting out of the vehicle’s battery pack.

According to Dr Shekhar, “Thermal runaway in a battery pack is majorly caused due to external causes such as short circuiting, accidental impact, or external potential and current changes. If these conditions are met, it can impact the battery performance and cause battery failure.

“Such conditions can potentially affect the battery performance, wherein it primarily is a failure of the electrolyte, leading to the connection of the positive and negative electrodes. This causes a short circuit, and an exothermic reaction which is chemical in nature,” he explained.

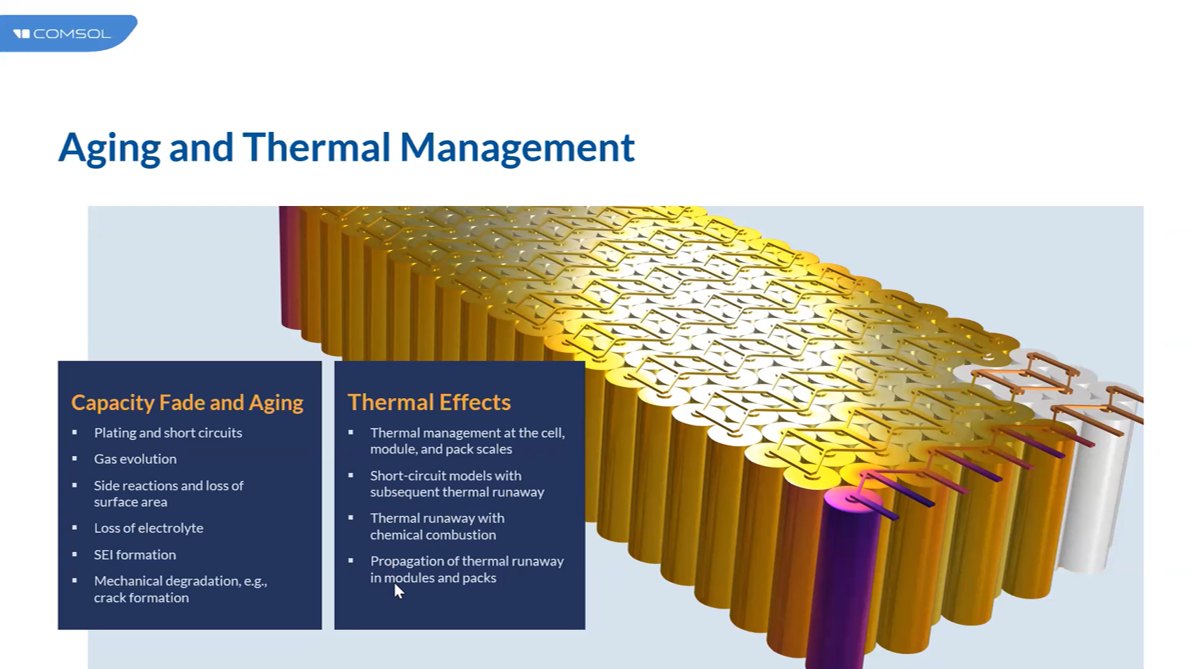

Robust thermal management of a lithium-ion battery pack is extremely important as poor thermal management could lead to battery ageing, or thermal runaway. As a result, the COMSOL Multiphysics simulation allows modelling of the battery pack across various conditions to optimise the thermal management of a battery pack to eliminate chances of failure.

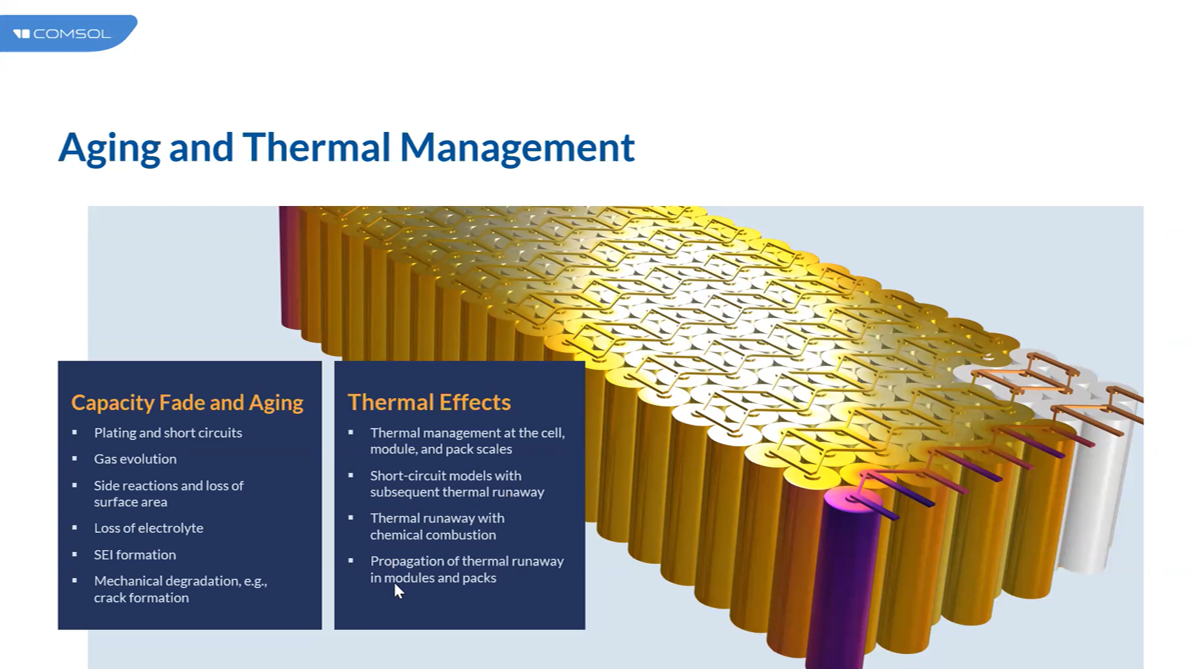

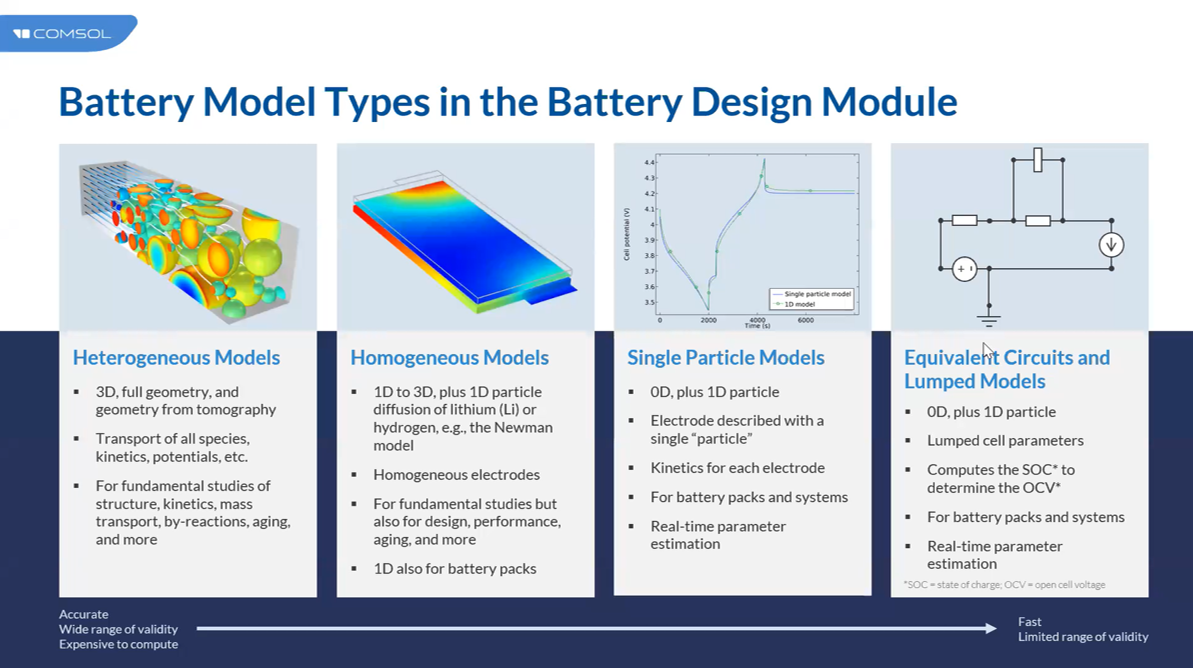

Battery modelling approach One can take various approaches to model a battery, including micro-scale-level modelling to pack-level modelling, as well as that ranging from 1D to 3D. Different models such as heterogeneous and homogenous models, single-particle models, and the more conventionally used equivalent circuits and lump models can also be evaluated.

One can take various approaches to model a battery, including micro-scale-level modelling to pack-level modelling, as well as that ranging from 1D to 3D. Different models such as heterogeneous and homogenous models, single-particle models, and the more conventionally used equivalent circuits and lump models can also be evaluated.

Dr Shekhar explained that while the electrochemistry allows one to go into the detail, and specifically model electrode particles, it is akin making a physical electrode – mixing two kinds of particles, getting binders, and coming up with a structure. “The physics of electrochemistry, mass transport, by-reactions and ageing, and other phenomenon taking place inside a battery. A heterogenous model allows working with real structures, and imposing models as geometries, to define physics to conduct the analyses,” he said.

On the other hand, homogenous models allow for cell-level analyses by modelling all the three layers – anode, cathode, and separator. While various failure mechanisms can be ascertained with the homogenous model, it is also used to conduct fundamental studies for design, performance, and ageing, among others.

Dr Shekhar further explained that in conditions where the cell is being modelled in zero-dimension, without involving any geometry, the single-particle model can enable kinetic analyses, on-board simulation as well as real-time parameter assessment. Lastly, the equivalent circuits and lumped models compute the state-of-charge and open-cell-voltage parameters of the battery, and aid battery pack and system analyses.

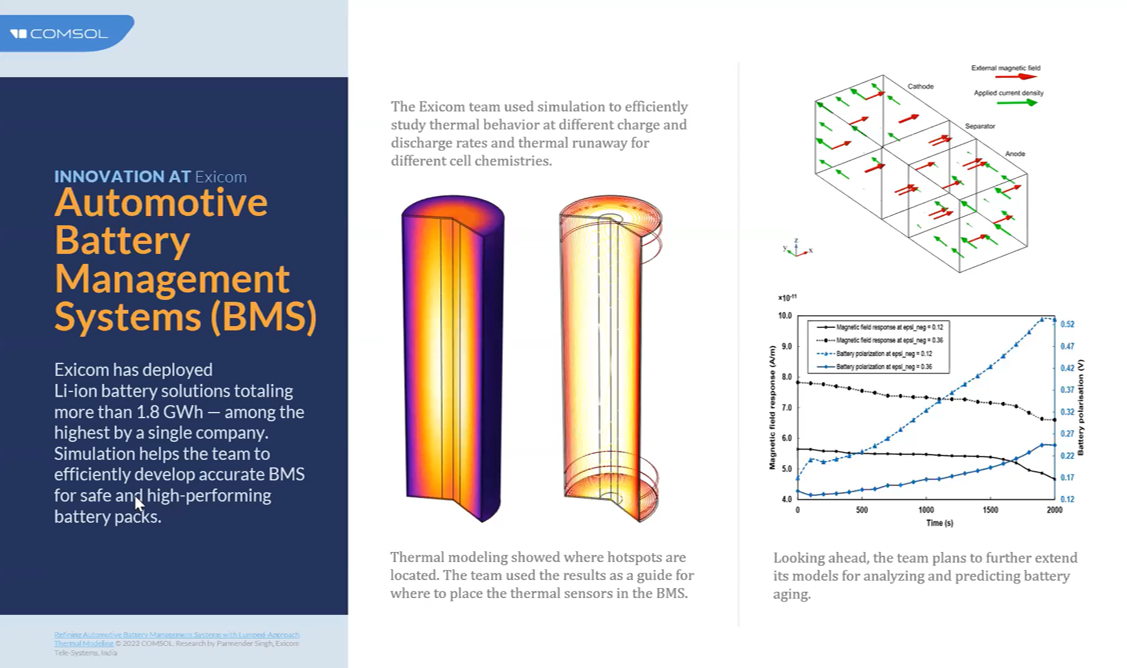

While these are the various models which can be leveraged to determine the battery pack modelling, citing a user case study from Exicom, which is an EV battery and charging solutions provider, Dr Shekhar mentioned that the company has been leveraging COMSOL Multiphysics simulation tools to efficiently develop accurate BMS for safe and high-performing battery packs. As per COMSOL, the Exicom team used simulation to efficiently study thermal behaviour at different charge and discharge rates, and thermal runaway for different cell chemistries.

While these are the various models which can be leveraged to determine the battery pack modelling, citing a user case study from Exicom, which is an EV battery and charging solutions provider, Dr Shekhar mentioned that the company has been leveraging COMSOL Multiphysics simulation tools to efficiently develop accurate BMS for safe and high-performing battery packs. As per COMSOL, the Exicom team used simulation to efficiently study thermal behaviour at different charge and discharge rates, and thermal runaway for different cell chemistries.