Global automotive manufacturer Peugeot has integrated Stratasys’ 3DFashion technology into the interior of its new Inception concept.

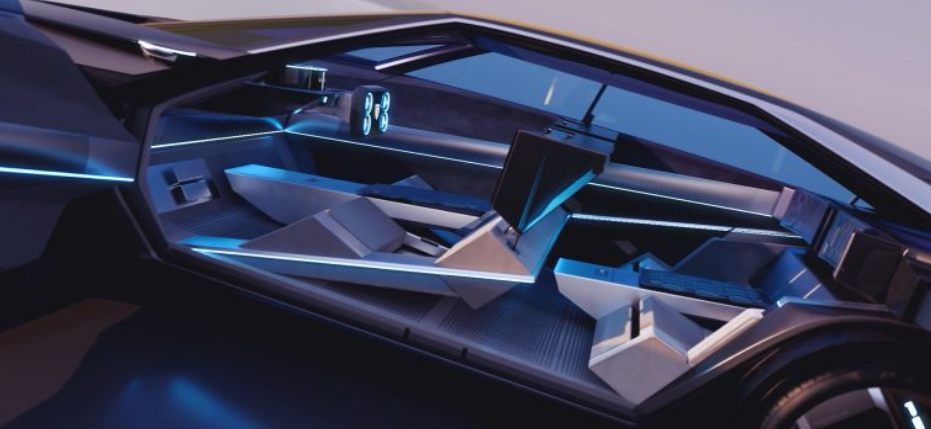

The manufacturer claims its novel embellishment methods helped achieve unprecedented resolution. The Inception concept, spearheaded by Peugeot’s Brand Design Director Matthias Hossann, represents a major change for the brand, reflecting its vision for electric vehicles, says the company. Peugeot describes the interior as “revolutionary” and features advanced materials made with Stratasys J850 TechStyle 3D printers.

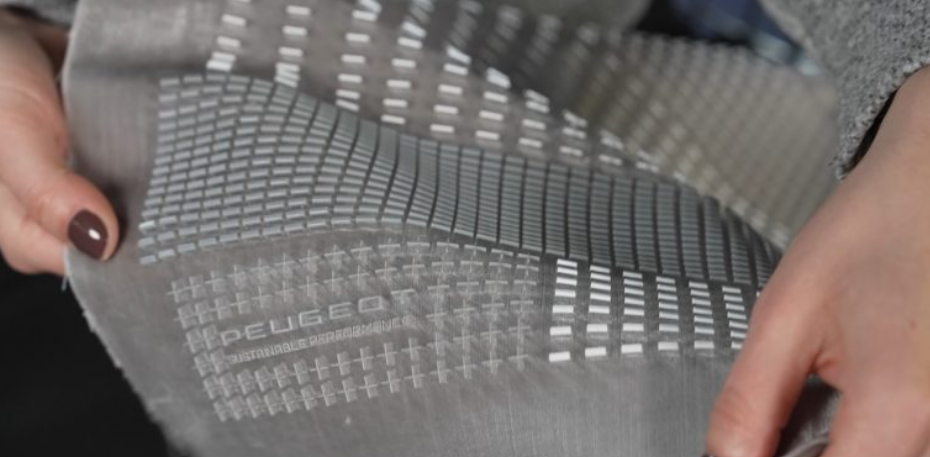

“At Peugeot, we always like to combine function with aesthetics,” said Maud Rondot, CMF Designer, Advanced Design Team at Peugeot, the department responsible for the future vision of the Peugeot brand. “Our objective with the Inception concept’s seating area was to modernize the velvet material used and decompartmentalize the design by extending it to also serve as a visually impactful floor mat.”

3D printed velvet interior transforms the Inception Concept

The interior of the Inception concept car reflects Peugeot’s new design principles for electric vehicles. It boasts a minimalist cockpit that is intended to improve the driver’s experience. Central to these features, the immersive seats are covered in velvet crafted from 100% recycled polyester. The velvet material extends seamlessly onto the floor, featuring intricate 3D patterns produced using “state-of-the-art” Stratasys 3D printing technology.

Rondot states that the Inception concept employs Stratasys’ direct-to-textile 3D printing for the floor area instead of protective overlays. This approach combines functionality, texture, and aesthetics in a distinct manner, which she believes is unattainable with other technologies. The concept’s core theme is the relationship between light and materials, which is achieved through carefully chosen materials that align with the car’s appearance.

Additionally, Peugeot adopted single-material effects to facilitate the transition to a fresh architecture, increased space, and decompartmentalization. As part of this approach, the team chose a metallic tone for the velvet upholstery, intending to manipulate light and evoke a futuristic ambiance. They utilized the J850 TechStyle 3D printer to produce semi-transparent ‘micro-architectures’ that align with this idea.

“Although we have access to relatively flat designs with current embellishment methods, it is not possible to build thickness and height. This is why we turned to Stratasys, and it is thanks to the company’s exclusive 3DFashion technology that we could 3D print directly onto the flexible material,” added Rondot. “Often, there is a delta between what we imagine and what we can obtain, so it was quite magical to see our idea arrive precisely as envisaged and with a remarkable quality of execution.”

On the road with 3D printing technologies

Europe’s leading carmaker Volkswagen recently acquired an extra MetalFAB 3D printing system from metal 3D printer manufacturer Additive Industries to advance automotive manufacturing. This move includes optimizing parameters and integrating MetalFAB’s Powder Load Tool and Powder Recovery Station to boost productivity. The MetalFAB system is equipped with full-field lasers and automated build changeovers, enabling rapid production rates and unmanned operations. Volkswagen’s decision to expand its MetalFAB collection is driven by the 3D printer’s advanced automation, which reduces manual processes and enhances safety.

Californian motor company Czinger Vehicles partnered with Xtrac, specialists in producing Motorsport & High Performance Automotive (HPA) gearboxes. This collaboration saw the development of a topology-optimized and additively manufactured gearbox. This novel gearbox is a 3D printed automated 7-speed semi-sequential transmission, making it a “significant achievement” in the industry, says the manufacturer. It was seamlessly integrated into Czinger’s 21C Hypercar. Notable features of the gearbox included rapid sub-100 millisecond shifts, the highest torque-to-mass ratio among road-legal vehicles, dual barrel gear actuation, and a 48V-electrically actuated twin barrel system.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the interior of Peugeot’s Inception Concept car uses velvet material that extends from the seats to the floor and features stunning 3D patterns created with Stratasys’ 3DFashion technology. Image via Stratasys.