“MAHLE will position itself as the system champion in e-mobility,” said Arnd Franz, Chairman of the MAHLE Management Board and CEO, during a Tech Day in the run-up to the IAA Mobility in Munich in September.

Systems expertise is a crucial success factor in electrification, Franz noted at the event held at Hydrogen Test Center in Stuttgart, which is owned by the Group. This is because the interaction of the individual components in electric drives is much more complex than in internal combustion engines.

The ‘perfect motor’

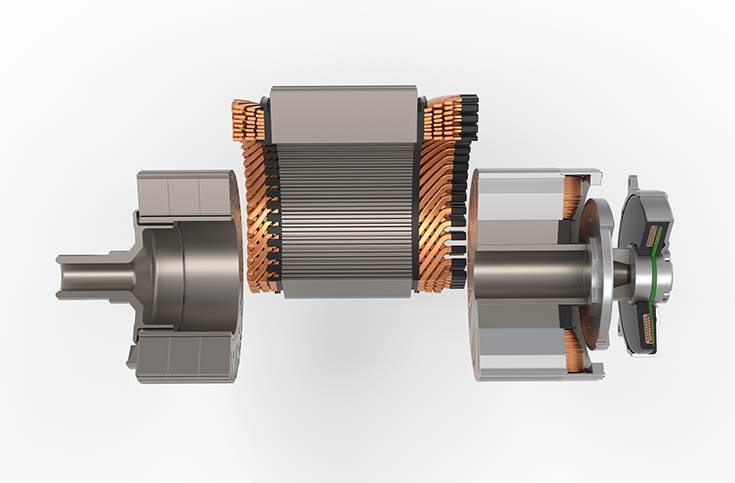

In the past two years, MAHLE introduced two highly innovative electric motors: the MCT (Magnet-free Contactless Transmitter), which operates contactless and without rare earths, and the endurance champion SCT (Superior Continuous Torque) electric motor. Now, for the first time, the Group is combining the characteristics of the two concepts in a technology kit. “With this unique construction kit for electric motors, we can offer our customers customised solutions,” Franz said.

With the new tech kit for e-motors, MAHLE is combining the advantages of its benchmark products SCT and MCT electric motors for the first time.

With the new tech kit for e-motors, MAHLE is combining the advantages of its benchmark products SCT and MCT electric motors for the first time.

MAHLE’s new technology kit for electric motors combines the advantages of the benchmark SCT and MCT electric motors. The ‘perfect motor’ combines permanently high peak power, contactless and thus wear-free power transmission, the elimination of rare earths, and the highest efficiency. In addition, MAHLE has developed a new thermal management module that brings together essential thermal management components. This reduces installation space, development effort and costs and makes the complete system significantly more efficient: Up to 20% more cruising range is possible — the battery needs to be charged less often. MAHLE will present both products to a broad audience for the first time at the IAA Mobility this September.

“Electrification is the topic of the future for MAHLE,” Franz said. Battery electric vehicles (BEVs) offer MAHLE a sales potential almost three times higher than vehicles with combustion engines. In this area, the Group is focusing on electric drives and intelligent charging. The aim is to increase cruising range and performance, as well as to advance fast-charging capability and charging convenience.

New automated positioning system for inductive charging technology has the vehicle detect the induction surface in the ground and provide positioning assistance to the driver.

New automated positioning system for inductive charging technology has the vehicle detect the induction surface in the ground and provide positioning assistance to the driver.

In terms of charging infrastructure, MAHLE is focusing on wireless charging in addition to wired solutions for long-term parkers (MAHLE chargeBIG) – a convenient and promising alternative for e-vehicles. Together with Siemens, MAHLE is developing a complete system comprising infrastructure and automotive engineering in order to set standards for inductive charging systems. During Tech Day, the automotive supplier unveiled a new automated positioning system for this charging technology, in which the vehicle detects the induction surface in the ground and provides positioning assistance to the driver.

The Group is also working on innovative products for independent workshops in the service and spare parts business. The latest example is a new vehicle- and manufacturer-independent battery diagnostic solution for electric vehicles, which MAHLE will launch in the current year. E-Health Charge combines charging and diagnostics and provides reliable information about the ‘health’ of the high-voltage battery. The measurement takes less than 15 minutes.

Efficient thermal management is what makes efficient e-mobility possible in the first place. Heating and cooling in vehicles is an essential technology field for electrification and a core business of MAHLE. “MAHLE has excellent expertise in both areas-electrification and thermal management. This enables thermal systems solutions for battery electric vehicles, hybrids and conventionally driven vehicles,” Franz said.

New thermal management module

In the case of the e-car, key end customer acceptance factors depend on thermal management: Service life of the battery, cruising range of the e-car, performance of the drive system and fast-charging capability. This significantly increases the complexity of the system. To reduce this complexity again while increasing efficiency, MAHLE has developed a new thermal management module. It combines, for example, a heat exchanger, coolant pumps, condenser, chiller, sensors and valves in one unit. This reduces installation space, development effort and costs. At the same time, the complete system becomes significantly more efficient: Up to 20 percent more cruising range can be achieved with the MAHLE module in a system network with a heat pump compared to a pure electric heater architecture. The higher cooling performance also improves fast charging capability.

The IAA Mobility will take place in Munich from September 4-10, 2023. MAHLE will present its technologies at the exhibition center (Summit) in Hall A2 and in the Testing Area in Hall C2.

With the new technology kit for electric motors, MAHLE is combining the advantages of its benchmark products SCT and MCT electric motors for the first time.